(c)PRECAUTIONS WHEN CONNECTING PIPES:

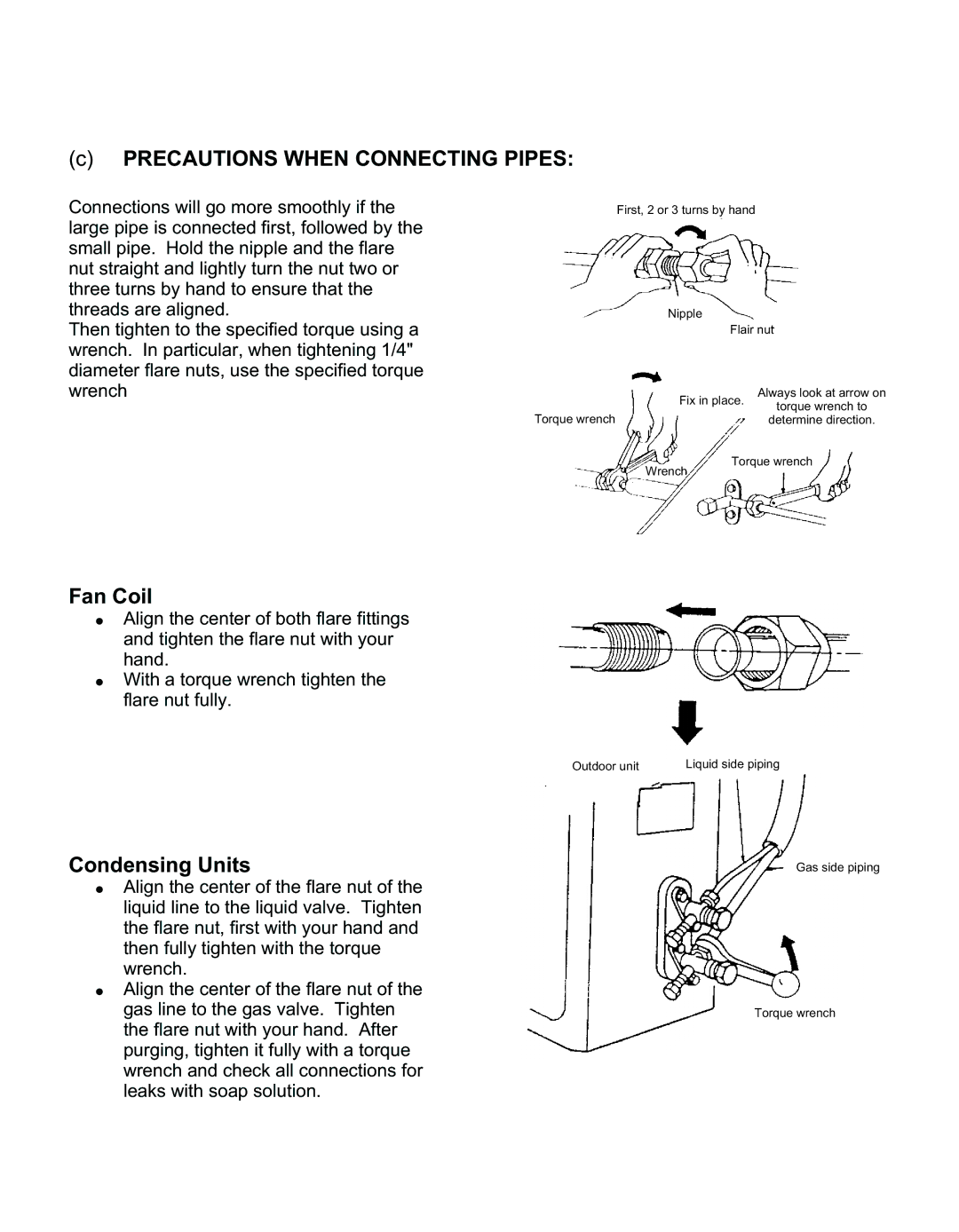

Connections will go more smoothly if the large pipe is connected first, followed by the small pipe. Hold the nipple and the flare nut straight and lightly turn the nut two or three turns by hand to ensure that the threads are aligned.

Then tighten to the specified torque using a wrench. In particular, when tightening 1/4" diameter flare nuts, use the specified torque wrench

First, 2 or 3 turns by hand

| Nipple |

|

| Flair nut | |

| Fix in place. | Always look at arrow on |

| torque wrench to | |

Torque wrench |

| |

| determine direction. | |

Torque wrench

Wrench

Fan Coil

!Align the center of both flare fittings and tighten the flare nut with your hand.

!With a torque wrench tighten the flare nut fully.

Condensing Units

!Align the center of the flare nut of the liquid line to the liquid valve. Tighten the flare nut, first with your hand and then fully tighten with the torque wrench.

!Align the center of the flare nut of the gas line to the gas valve. Tighten the flare nut with your hand. After purging, tighten it fully with a torque wrench and check all connections for leaks with soap solution.

Outdoor unit | Liquid side piping |

Gas side piping

Torque wrench