Blown Air Drying

Blown Air Drying Remove the covers from all apertures to allow the escape of

the water-laden air. During drying, air must be able to flow

freely through the generator in order to carry off the moisture.

Direct hot air from two electrical fan heaters of around 1 – 3

kW into the generator air inlet apertures. Ensure the heat

source is at least 300mm away from the windings to avoid

over heating and damage to the insulation.

Apply the heat and plot the insulation value at half hourly

intervals. The process is complete when the parameters

covered in the section entitled, ‘Typical Drying Out Curve’, are

met.

Remove the heaters, replace all covers and re-commission as

appropriate.

If the set is not to be run immediately ensure that the

anticondensation heaters are energised, and retest prior to

running.

Short Circuit Method

NOTE: This process should only be performed by a

competent engineer familiar with safe operating practices

within and around generator sets of the type in question.

Ensure the generator is safe to work on, initiate all mechanical

and electrical safety procedures pertaining to the genset and

the site.

Bolt a short circuit of adequate current carrying capacity,

across the main terminals of the generator. The shorting link

should be capable of taking full load current.

Disconnect the cables from terminals “X” and “XX” of the

AVR.

Connect a variable dc supply to the “X” (positive) and “XX”

(negative) field cables. The dc supply must be able to provide

a current up to 2.0 Amp at 0 - 24 Volts.

Position a suitable ac ammeter to measure the shorting link

current.

Set the dc supply voltage to zero and start the generating set.

Slowly increase the dc voltage to pass current through the

exciter field winding. As the excitation current increases, so

the stator current in the shorting link will increase. This stator

output current level must be monitored, and not allowed to

exceed 80% of the generators rated output current.

After every 30 minutes of this exercise:

Stop the generator and switch off the separate excitation

supply, and measure and record the stator winding IR values,

and plot the results. The resulting graph should be compared

with the classic shaped graph. This drying out procedure is

complete when the parameters covered in the section entitled

'Typical Drying Out Curve' are met.

Once the Insulation Resistance is raised to an acceptable

level - minimum value 1.0 MΩ − the dc supply may be

removed and the exciter field leads “X” and “XX” re-connected

to their terminals on the AVR.

Rebuild the genset, replace all covers and re-commission as

appropriate.

If the set is not to be run immediately ensure that the

anticondensation heaters are energised, and retest the

generator prior to running.

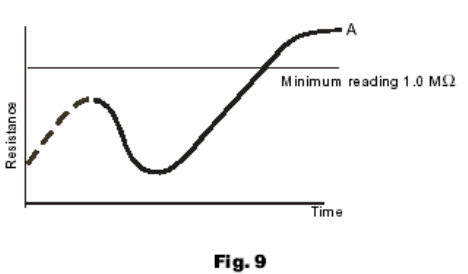

Whichever method is used to dry out the generator the

resistance should be measured every half-hour and a curve

plotted as shown. (fig 6.)

The illustration shows a typical curve for a machine that has

absorbed a considerable amount of moisture. The curve

indicates a temporary increase in resistance, a fall and then a

gradual rise to a steady state. Point ‘A’, the steady state, must

be greater than 1.0 MΩ. (If the windings are only slightly

damp the dotted portion of the curve may not appear).

For general guidance expect that the typical time to reach

point 'A' will be :

1 hour for a BC16/18,

2 hours for a UC22/27

3 hours for an HC4,5,6&7

Drying should be continued after point “A” has been reached

for at least one hour.

It should be noted that as winding temperature increases,

values of insulation resistance may significantly reduce.

Therefore, the reference values for insulation resistance can

only be established with windings at a temperature of

approximately 20°C.

If the IR value remains below 1.0 MΩ, even after the above

drying methods have been properly conducted, then a

Polarisation Index test [PI] should be carried out.

If the minimum value of 1.0 MΩ for all components cannot be

achieved rewinding or refurbishment of the generator will be

necessary.

The generator must not be put into service until the

minimum values can be achieved.

Important ! The short circuit must not be applied with

the AVR connected in circuit. Current in

excess of the rated generator current will

cause damage to the windings.

After drying out, the insulation resistances should be

rechecked to verify minimum resistances quoted above are

achieved.

On re-testing it is recommended that the main stator

insulation resistance is checked as follows :-

Separate the neutral leads