ASSEMBLY

NOTE: This tool is shipped completely assembled. No assembly time or tools are required.

OPERATION

TO START AND STOP SAW

1.Make sure power circuit voltage is the same as that shown on the specification plate on the saw. Connect machine to power circuit.

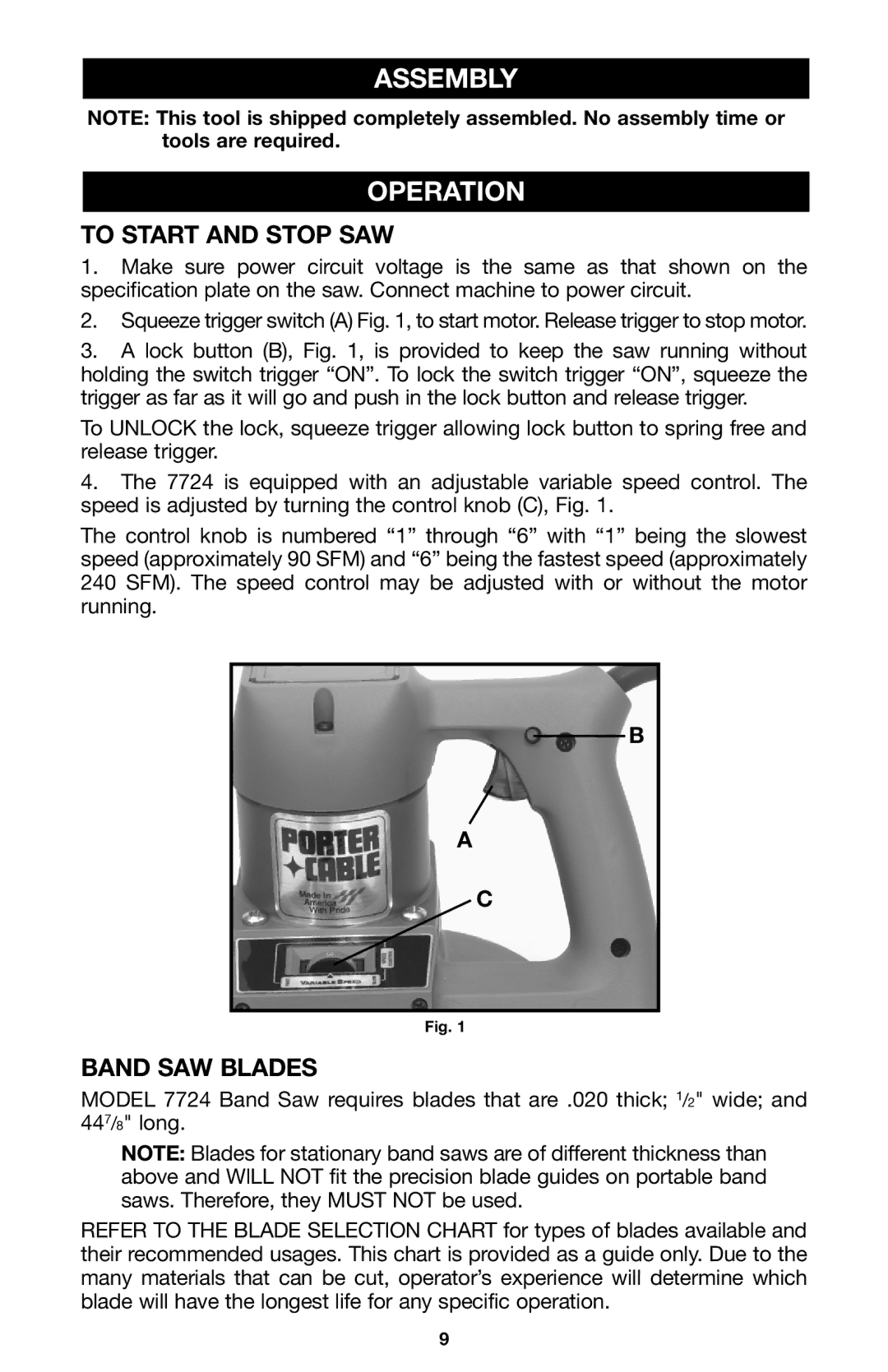

2.Squeeze trigger switch (A) Fig. 1, to start motor. Release trigger to stop motor.

3.A lock button (B), Fig. 1, is provided to keep the saw running without holding the switch trigger “ON”. To lock the switch trigger “ON”, squeeze the trigger as far as it will go and push in the lock button and release trigger.

To UNLOCK the lock, squeeze trigger allowing lock button to spring free and release trigger.

4.The 7724 is equipped with an adjustable variable speed control. The speed is adjusted by turning the control knob (C), Fig. 1.

The control knob is numbered “1” through “6” with “1” being the slowest speed (approximately 90 SFM) and “6” being the fastest speed (approximately 240 SFM). The speed control may be adjusted with or without the motor running.

B

A

C

Fig. 1

BAND SAW BLADES

MODEL 7724 Band Saw requires blades that are .020 thick; 1/2" wide; and 447/8" long.

NOTE: Blades for stationary band saws are of different thickness than above and WlLL NOT fit the precision blade guides on portable band saws. Therefore, they MUST NOT be used.

REFER TO THE BLADE SELECTlON CHART for types of blades available and their recommended usages. This chart is provided as a guide only. Due to the many materials that can be cut, operator’s experience will determine which blade will have the longest life for any specific operation.

9