|

| C |

|

|

|

|

|

|

D |

|

|

|

|

| C |

|

|

| B |

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

A |

|

|

|

| A | B |

| A |

|

|

|

|

|

| |||

|

| A |

|

|

|

| ||

|

|

|

|

|

|

|

| |

Fig. 1 |

|

|

| Fig. 2 | Fig. 3 |

|

|

|

|

|

|

|

|

|

|

| Fig. 4A |

|

| H | E |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

| F |

|

|

|

|

| A |

|

|

|

|

|

|

|

| |

|

|

| O |

|

|

| B |

|

|

| G |

|

|

|

|

|

|

|

|

| I |

|

|

| C | A |

|

|

|

|

|

| K | ||

|

|

|

|

|

|

|

| Fig. 4B |

|

|

|

|

|

| L |

|

|

|

| S | J |

|

|

| M |

|

|

|

|

|

|

|

| ||

|

| Fig. 5 |

|

|

| Fig. 6 |

|

|

|

|

| N |

|

|

|

| |

|

|

|

|

|

|

|

| |

| A | A |

|

|

| Fig. 7 | A | R |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| K | ||

| B |

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

| P | ||||

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Fig. 9 |

|

|

|

| Fig. 11 |

|

| Fig. 8 |

|

|

|

|

|

|

| Fig. 10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

L |

| 1. ROUTER BASE | 1. BASE DE LA TOUPIE | A | A | ||

| 2. | 2. | |||||

J | D | 3. ROUTER BIT | 3. MÈCHE DE TOUPIE | SCREW | D | ||

| |||||||

H |

| 4. TEMPLET GUIDE | 4. GUIDE DE GABARIT |

|

| ||

| 5. LOCKNUT | 5. |

|

| |||

B |

| 1. BASE DEL REBAJADORA |

| C | |||

A |

|

| |||||

| 2. |

|

|

| |||

|

|

|

| B | |||

|

| 3. BROCA |

|

|

| ||

| C | 4. GUIA DE PATRON |

|

|

| ||

K | 5. TUERCA INAFLOJABLE | Fig. 14 | Fig. 15 | ||||

| |||||||

|

|

|

|

|

| ||

|

| 5 |

| 1 |

|

| |

F | E |

|

|

| E |

| |

|

|

| B |

| |||

G |

|

|

|

|

|

| |

| Fig. 12 | 4 |

| Fig. 13 |

|

| |

|

| 2 |

|

| |||

|

| 3 |

|

|

| ||

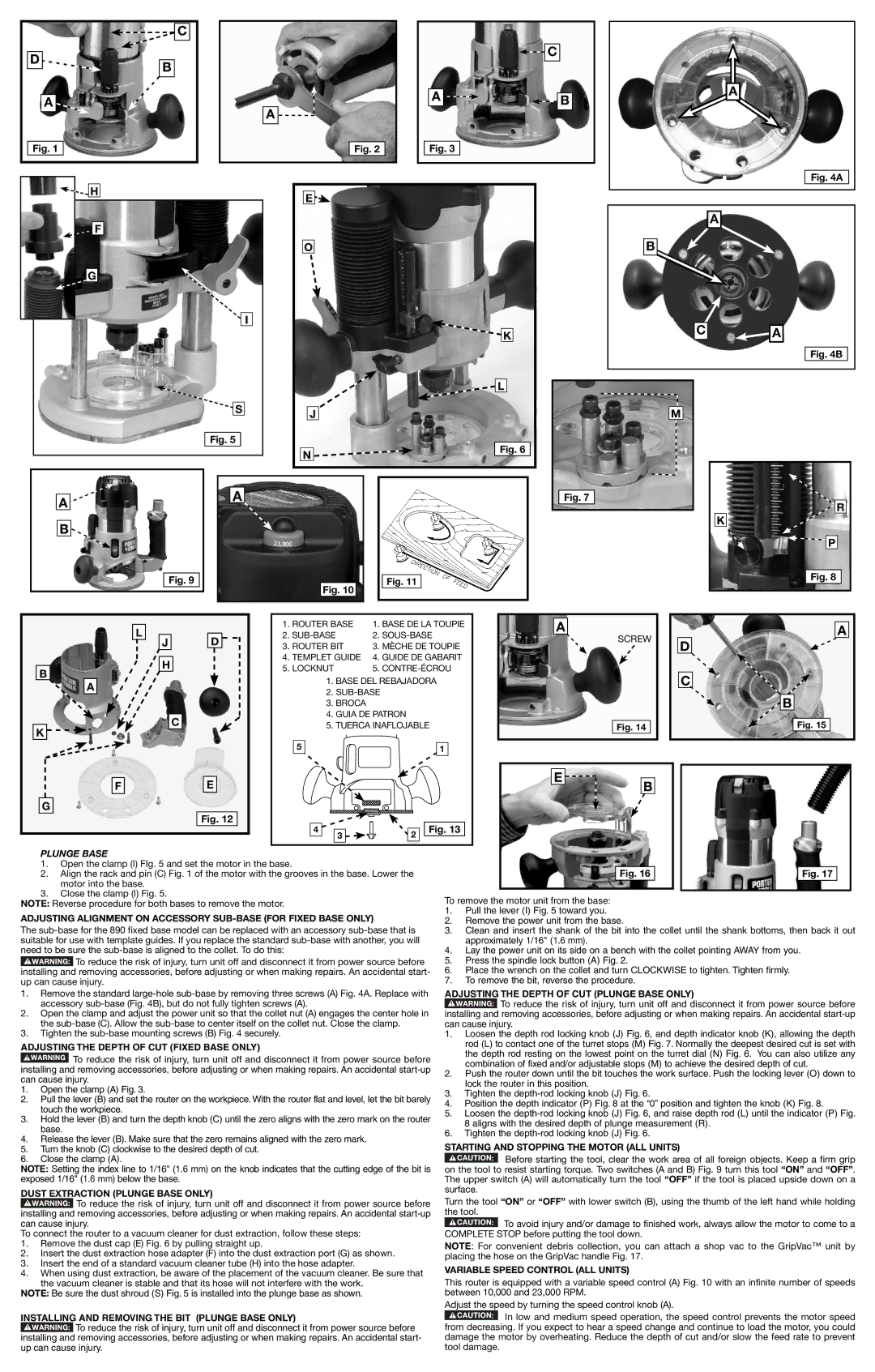

PLUNGE BASE

1.Open the clamp (I) FIg. 5 and set the motor in the base.

2. Align the rack and pin (C) Fig. 1 of the motor with the grooves in the base. Lower the | Fig. 16 | Fig. 17 | |

motor into the base. |

|

|

|

|

|

| |

3.Close the clamp (I) Fig. 5.

NOTE: Reverse procedure for both bases to remove the motor. | To remove the motor unit from the base: | ||||||||

ADJUSTING ALIGNMENT ON ACCESSORY | 1. | Pull the lever (I) Fig. 5 toward you. | |||||||

2. | Remove the power unit from the base. | ||||||||

The | 3. | Clean and insert the shank of the bit into the collet until the shank bottoms, then back it out | |||||||

suitable for use with template guides. If you replace the standard |

|

| approximately 1/16" (1.6 mm). | ||||||

need to be sure the | 4. | Lay the power unit on its side on a bench with the collet pointing AWAY from you. | |||||||

|

|

| To reduce the risk of injury, turn unit off and disconnect it from power source before | 5. | Press the spindle lock button (A) Fig. 2. | ||||

installing and | removing accessories, before adjusting or when making repairs. An accidental start- | 6. | Place the wrench on the collet and turn CLOCKWISE to tighten. Tighten firmly. | ||||||

up can cause injury. | 7. | To remove the bit, reverse the procedure. | |||||||

1. Remove the standard | ADJUSTING THE DEPTH OF CUT (PLUNGE BASE ONLY) | ||||||||

accessory |

|

|

|

|

| To reduce the risk of injury, turn unit off and disconnect it from power source before | |||

2.Open the clamp and adjust the power unit so that the collet nut (A) engages the center hole in installing and removing accessories, before adjusting or when making repairs. An accidental

| the | can cause injury. | ||||||||||

3. | Tighten the | 1. Loosen the depth rod locking knob (J) Fig. 6, and depth indicator knob (K), allowing the depth | ||||||||||

ADJUSTING THE DEPTH OF CUT (FIXED BASE ONLY) |

| rod (L) to contact one of the turret stops (M) Fig. 7. Normally the deepest desired cut is set with | ||||||||||

| the depth rod resting on the lowest point on the turret dial (N) Fig. 6. You can also utilize any | |||||||||||

|

|

|

| To reduce the risk of injury, turn unit off and disconnect it from power source before |

| |||||||

installing and removing accessories, before adjusting or when making repairs. An accidental |

| combination of fixed and/or adjustable stops (M) to achieve the desired depth of cut. | ||||||||||

2. | Push the router down until the bit touches the work surface. Push the locking lever (O) down to | |||||||||||

can cause injury. | ||||||||||||

| lock the router in this position. | |||||||||||

1. | Open the clamp (A) Fig. 3. |

| ||||||||||

3. | Tighten the | |||||||||||

2. | Pull the lever (B) and set the router on the workpiece. With the router flat and level, let the bit barely | |||||||||||

4. | Position the depth indicator (P) Fig. 8 at the “0” position and tighten the knob (K) Fig. 8. | |||||||||||

| touch the workpiece. | |||||||||||

| 5. | Loosen the | ||||||||||

3. | Hold the lever (B) and turn the depth knob (C) until the zero aligns with the zero mark on the router | |||||||||||

| 8 aligns with the desired depth of plunge measurement (R). | |||||||||||

| base. |

| ||||||||||

| 6. | Tighten the | ||||||||||

4. | Release the lever (B). Make sure that the zero remains aligned with the zero mark. | |||||||||||

STARTING AND STOPPING THE MOTOR (ALL UNITS) | ||||||||||||

5. | Turn the knob (C) clockwise to the desired depth of cut. | |||||||||||

6. | Close the clamp (A). |

|

|

|

| Before starting the tool, clear the work area of all foreign objects. Keep a firm grip | ||||||

NOTE: Setting the index line to 1/16" (1.6 mm) on the knob indicates that the cutting edge of the bit is | on the tool to resist starting torque. Two switches (A and B) Fig. 9 turn this tool “ON” and “OFF”. | |||||||||||

exposed 1/16" (1.6 mm) below the base. | The upper switch (A) will automatically turn the tool “OFF” if the tool is placed upside down on a | |||||||||||

DUST EXTRACTION (PLUNGE BASE ONLY) | surface. | |||||||||||

Turn the tool “ON” or “OFF” with lower switch (B), using the thumb of the left hand while holding | ||||||||||||

|

|

|

|

| To reduce the risk of injury, turn unit off and disconnect it from power source before | |||||||

installing and removing accessories, before adjusting or when making repairs. An accidental | the tool. | |||||||||||

can cause injury. |

|

|

|

|

| To avoid injury and/or damage to finished work, always allow the motor to come to a | ||||||

To connect the router to a vacuum cleaner for dust extraction, follow these steps: | COMPLETE STOP before putting the tool down. | |||||||||||

1. | Remove the dust cap (E) Fig. 6 by pulling straight up. | NOTE: For convenient debris collection, you can attach a shop vac to the GripVac™ unit by | ||||||||||

2. | Insert the dust extraction hose adapter (F) into the dust extraction port (G) as shown. | placing the hose on the GripVac handle Fig. 17. | ||||||||||

3. | Insert the end of a standard vacuum cleaner tube (H) into the hose adapter. | VARIABLE SPEED CONTROL (ALL UNITS) | ||||||||||

4. | When using dust extraction, be aware of the placement of the vacuum cleaner. Be sure that | |||||||||||

This router is equipped with a variable speed control (A) Fig. 10 with an infinite number of speeds | ||||||||||||

| the vacuum cleaner is stable and that its hose will not interfere with the work. | |||||||||||

NOTE: Be sure the dust shroud (S) Fig. 5 is installed into the plunge base as shown. | between 10,000 and 23,000 RPM. | |||||||||||

|

|

|

|

|

|

| Adjust the speed by turning the speed control knob (A). | |||||

INSTALLING AND REMOVING THE BIT (PLUNGE BASE ONLY) |

|

|

|

|

| In low and medium speed operation, the speed control prevents the motor speed | ||||||

|

|

|

|

| ||||||||

|

|

|

|

| To reduce the risk of injury, turn unit off and disconnect it from power source before | from decreasing. If you expect to hear a speed change and continue to load the motor, you could | ||||||

installing and removing accessories, before adjusting or when making repairs. An accidental start- | damage the motor by overheating. Reduce the depth of cut and/or slow the feed rate to prevent | |||||||||||

up can cause injury. | tool damage. | |||||||||||