To Drain Tank

NOTE: Operation of the air compressor will cause condensation to build up in the air tank. Always drain tank on a washable surface or in a suitable container to prevent damaging or staining surfaces.

1.Set the On/Auto/Off lever to "Off".

2.Close the globe valve.

3.Remove the air tool or accessory.

4.Open the globe valve and allow the air to slowly bleed from the air tank until tank pressure is approximately 20 psi.

5.Close the globe valve.

6.Drain water from air tank by opening drain valve on

bottom of tank.

Risk of

Bursting. Water will condense in the air tank. If not drained, water will corrode and weaken the air tank causing a risk of air tank rupture.

7.After the water has been drained, close the drain valve. The air

compressor can now be stored.

NOTE: If drain valve is

plugged, release all air pressure. The valve can then be removed, cleaned, then reinstalled.

Oil

NOTE: Use an oil specifically formulated for use in an air compressor, such as

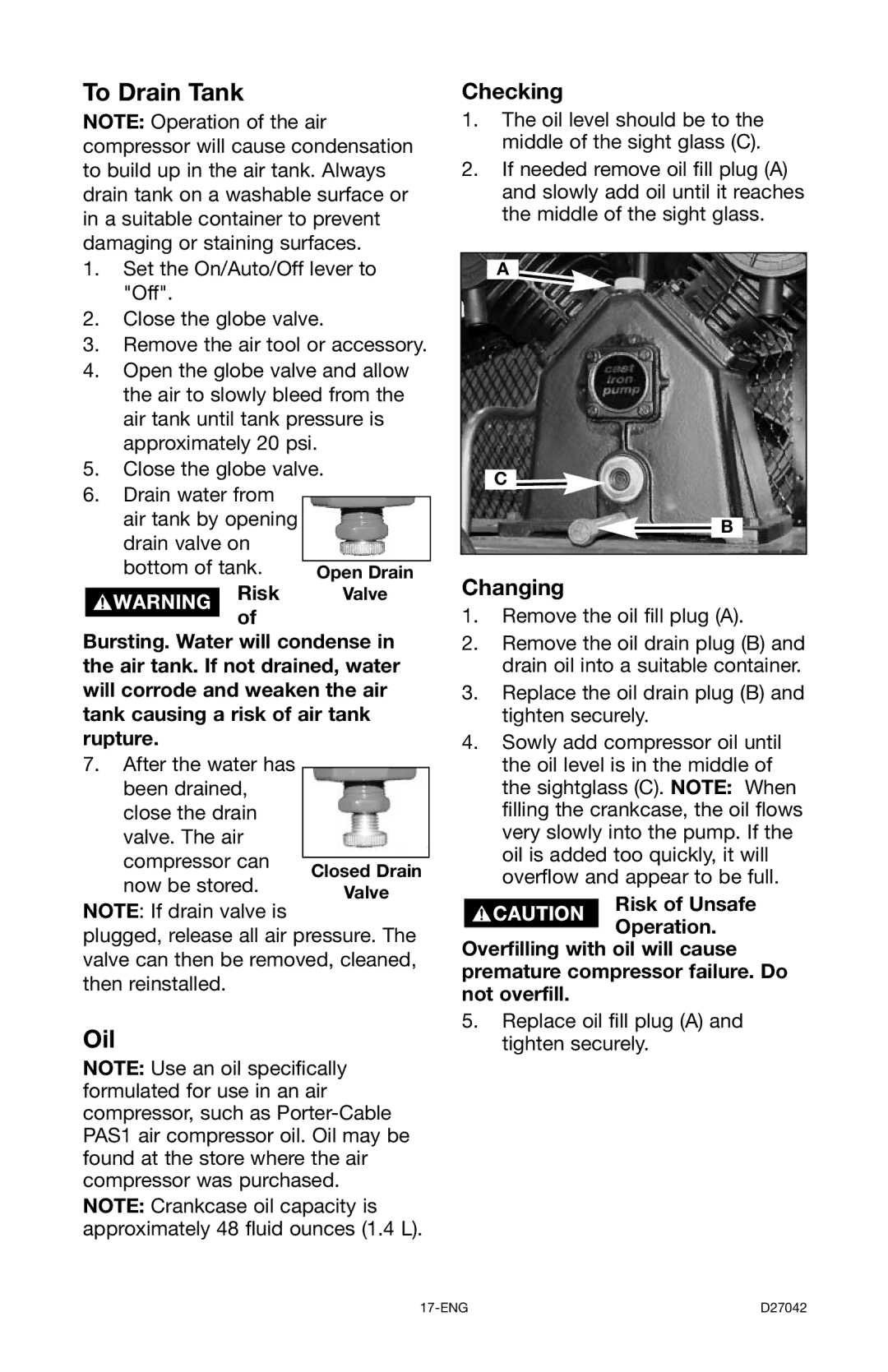

Checking

1.The oil level should be to the middle of the sight glass (C).

2.If needed remove oil fill plug (A) and slowly add oil until it reaches the middle of the sight glass.

A

C ![]()

![]() B

B

Changing

1.Remove the oil fill plug (A).

2.Remove the oil drain plug (B) and drain oil into a suitable container.

3.Replace the oil drain plug (B) and tighten securely.

4.Sowly add compressor oil until the oil level is in the middle of the sightglass (C). NOTE: When filling the crankcase, the oil flows very slowly into the pump. If the oil is added too quickly, it will overflow and appear to be full.

Risk of Unsafe Operation.

Overfilling with oil will cause premature compressor failure. Do not overfill.

5.Replace oil fill plug (A) and tighten securely.

D27042 |