ACCESSORIES

Accessories for this unit are available at the store the unit was purchased.

ASSEMBLY

To Add Oil To Pump

DO NOT ATTEMPT TO OPERATE THIS AIR COMPRESSOR WITHOUT FIRST ADDING OIL TO THE

CRANKCASE. Serious damage can result from even limited operation unless filled with oil and broken in correctly. Make sure to closely follow initial

COMPRESSORS ARE SHIPPED WITHOUT OIL. A small amount of oil may be present in the pump upon receipt of the air compressor. This is due to plant testing and does not mean the

pump contains oil.

on critical components, thus reducing performance and compressor life. Use air compressor oil only.

NOTE: Use an air compressor oil such as

1.Place unit on a level surface.

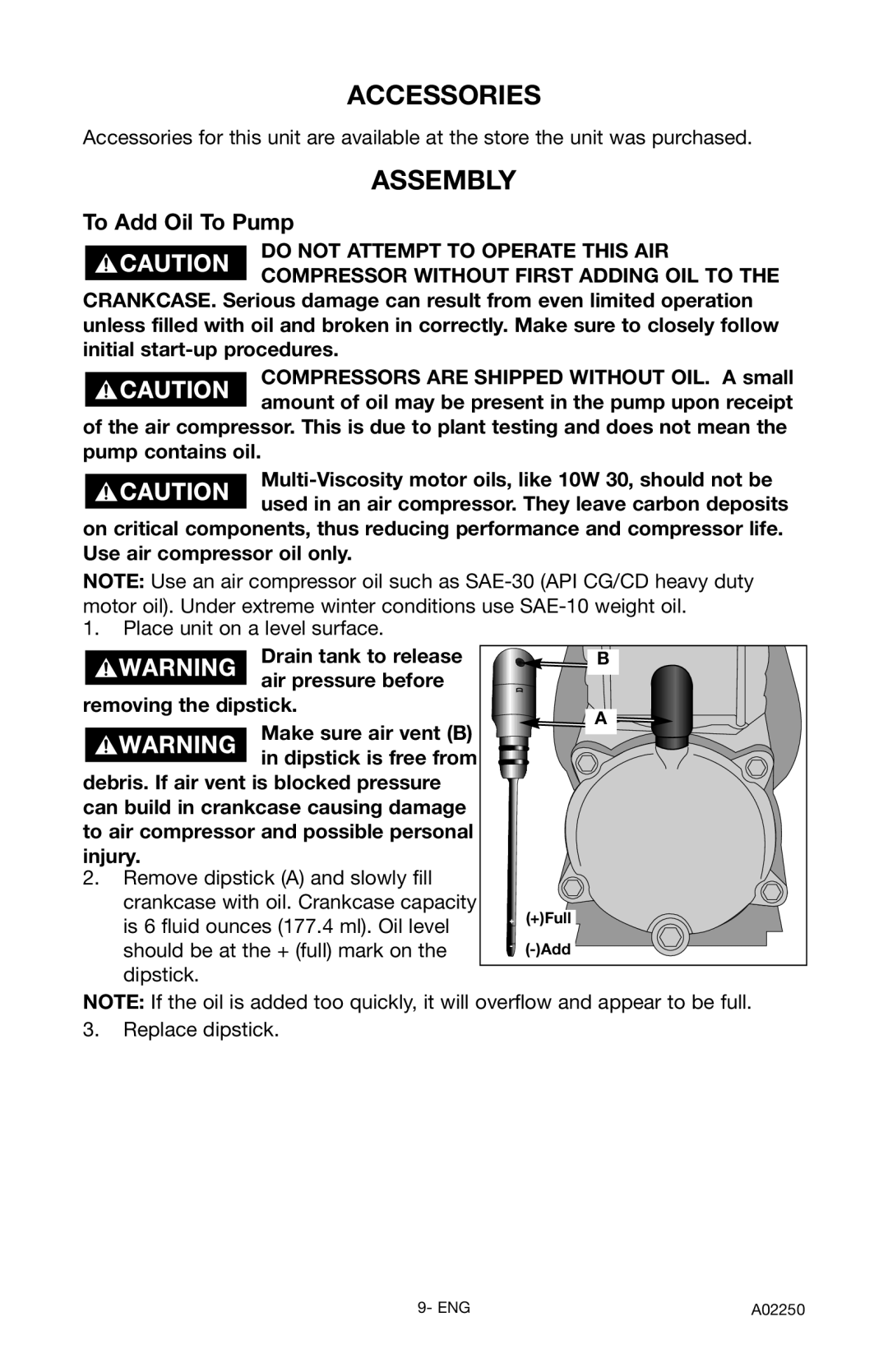

Drain tank to release |

| B |

air pressure before |

|

|

removing the dipstick. |

| A |

Make sure air vent (B) |

| |

|

| |

in dipstick is free from |

|

|

debris. If air vent is blocked pressure |

|

|

can build in crankcase causing damage |

|

|

to air compressor and possible personal |

|

|

injury. |

|

|

2. Remove dipstick (A) and slowly fill |

|

|

crankcase with oil. Crankcase capacity |

| (+)Full |

is 6 fluid ounces (177.4 ml). Oil level | + | |

|

| |

should be at the + (full) mark on the | - | |

| ||

dipstick. |

|

|

NOTE: If the oil is added too quickly, it will overflow and appear to be full. | ||

3.Replace dipstick.

9- ENG | A02250 |