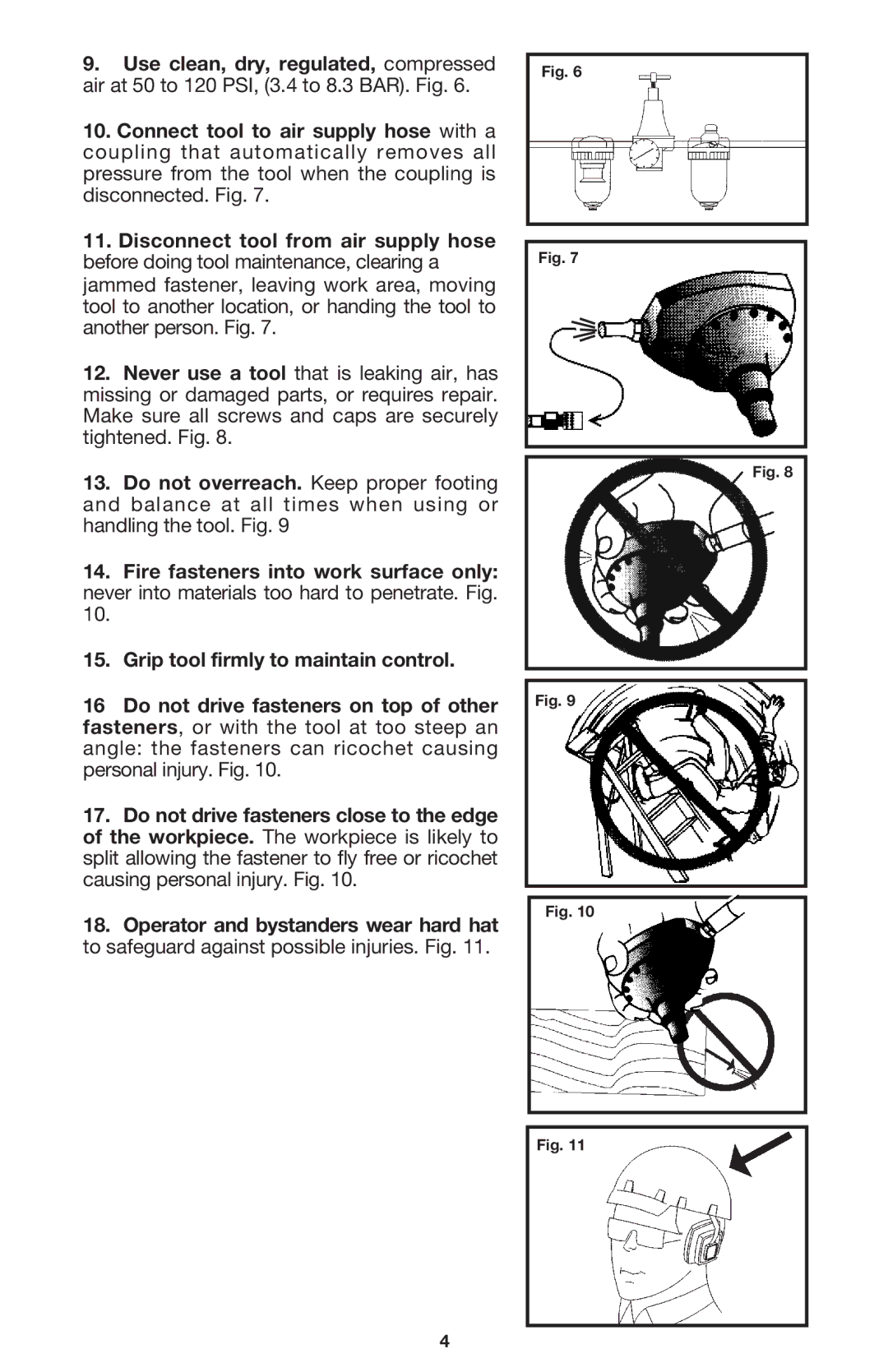

9.Use clean, dry, regulated, compressed air at 50 to 120 PSI, (3.4 to 8.3 BAR). Fig. 6.

10.Connect tool to air supply hose with a coupling that automatically removes all

pressure from the tool when the coupling is disconnected. Fig. 7.

11.Disconnect tool from air supply hose before doing tool maintenance, clearing a

jammed fastener, leaving work area, moving tool to another location, or handing the tool to

another person. Fig. 7.

12.Never use a tool that is leaking air, has missing or damaged parts, or requires repair.

Make sure all screws and caps are securely tightened. Fig. 8.

13.Do not overreach. Keep proper footing and balance at all times when using or

handling the tool. Fig. 9

14.Fire fasteners into work surface only: never into materials too hard to penetrate. Fig.

15.Grip tool firmly to maintain control.

16Do not drive fasteners on top of other fasteners, or with the tool at too steep an angle: the fasteners can ricochet causing personal injury. Fig. 10.

17.Do not drive fasteners close to the edge of the workpiece. The workpiece is likely to split allowing the fastener to fly free or ricochet causing personal injury. Fig. 10.

18.Operator and bystanders wear hard hat to safeguard against possible injuries. Fig. 11.

Fig. 6

Fig. 7

Fig. 8

Fig. 9

Fig. 10

Fig. 11

4