Fig. 19 | A |

| B |

A B

Fig. 20

HAMMER ASSEMBLY

1.![]() WARNING: Disconnect tool from air supply.

WARNING: Disconnect tool from air supply.

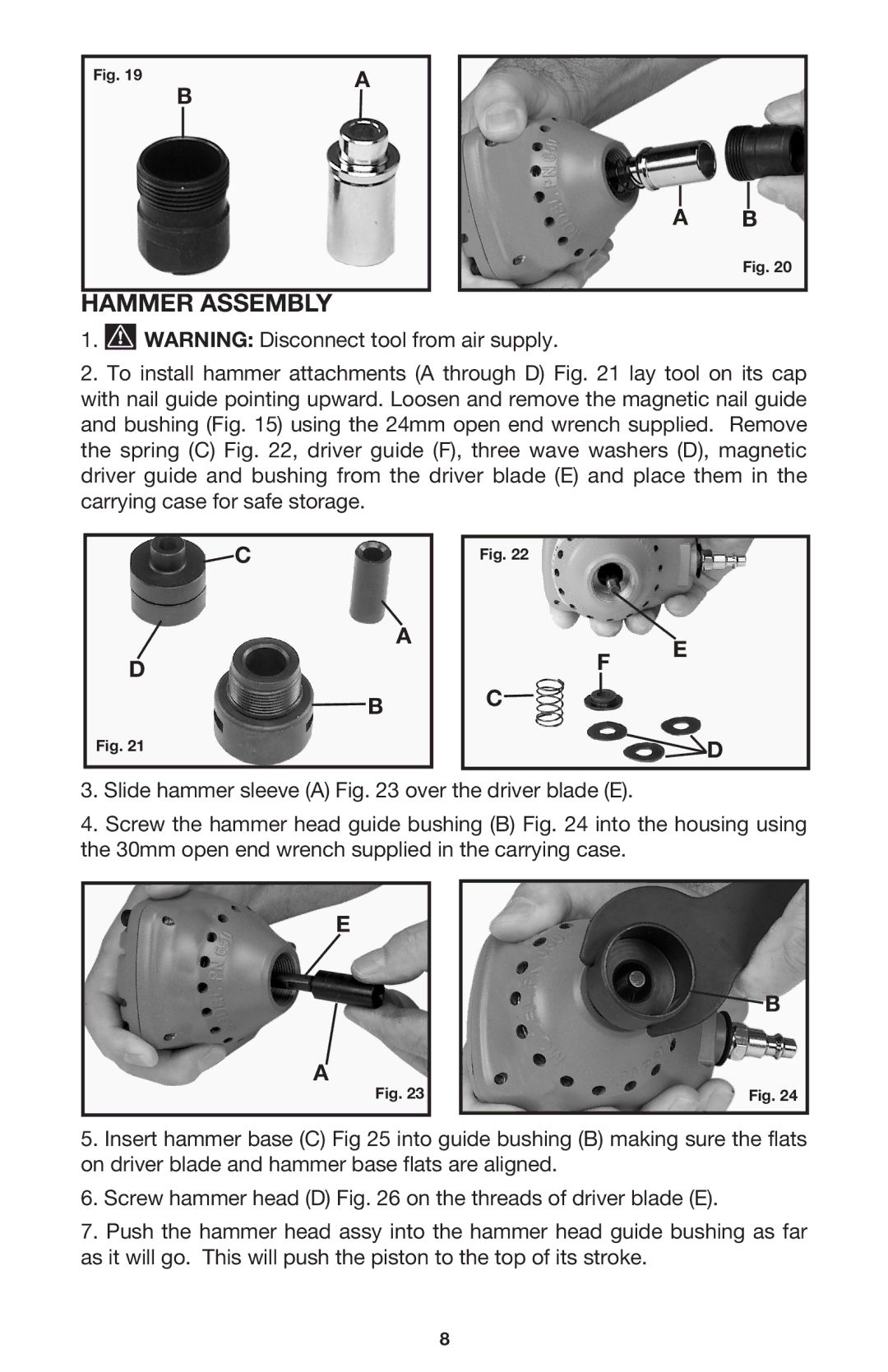

2.To install hammer attachments (A through D) Fig. 21 lay tool on its cap with nail guide pointing upward. Loosen and remove the magnetic nail guide and bushing (Fig. 15) using the 24mm open end wrench supplied. Remove the spring (C) Fig. 22, driver guide (F), three wave washers (D), magnetic driver guide and bushing from the driver blade (E) and place them in the carrying case for safe storage.

![]() C

C

A

D

B

Fig. 22

F

C

E

Fig. 21

![]() D

D

3.Slide hammer sleeve (A) Fig. 23 over the driver blade (E).

4.Screw the hammer head guide bushing (B) Fig. 24 into the housing using the 30mm open end wrench supplied in the carrying case.

E

A

Fig. 23

![]() B

B

Fig. 24

5.Insert hammer base (C) Fig 25 into guide bushing (B) making sure the flats on driver blade and hammer base flats are aligned.

6.Screw hammer head (D) Fig. 26 on the threads of driver blade (E).

7.Push the hammer head assy into the hammer head guide bushing as far as it will go. This will push the piston to the top of its stroke.

8