out should something go wrong under the cutterhead. A pressure bar located close to the cutterhead increases the stability of the wood to help the POWERMATIC

PM201HH, 22" Planer produce an exceptional finish. Infeed and outfeed rollers, cutterhead and many other rotating parts turn in high quality roller bearings that extend their lifespan, increase accuracy and reduce maintenance.

The

different thicknesses through the POWERMATIC PM201HH, 22" Planer simultaneously. This feed system also

accepts work pieces with uneven surfaces, moving them consistently so they are machined correctly the first time.

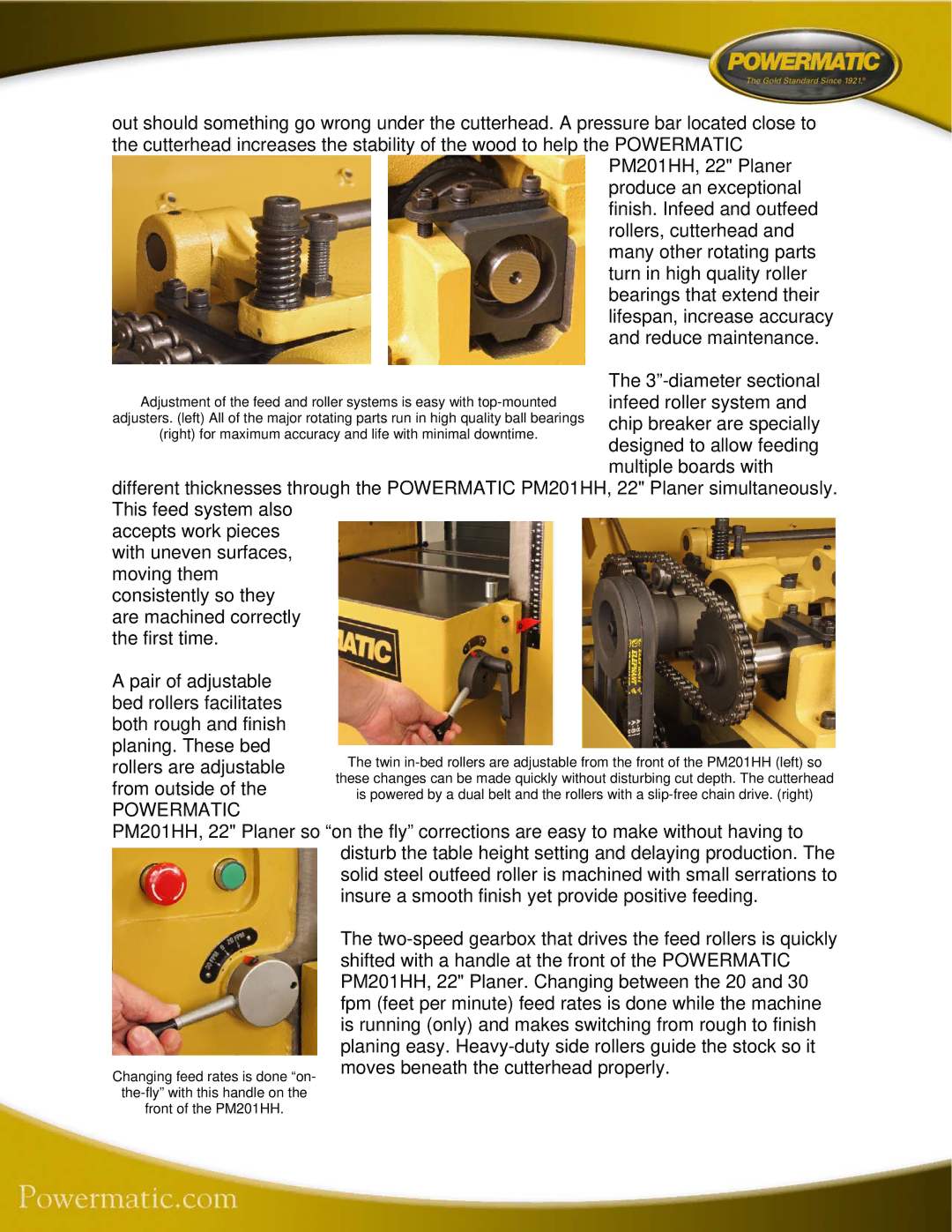

A pair of adjustable bed rollers facilitates both rough and finish planing. These bed rollers are adjustable from outside of the

POWERMATIC

PM201HH, 22" Planer so “on the fly” corrections are easy to make without having to disturb the table height setting and delaying production. The solid steel outfeed roller is machined with small serrations to insure a smooth finish yet provide positive feeding.

Changing feed rates is done “on-

The