the motor is tightly held in place. I found that pulling the wire taut with my needle nose pliers helped me snug it up into its proper position. Repeat this procedure for the other motor using the other outline on the top of the board as a guide.

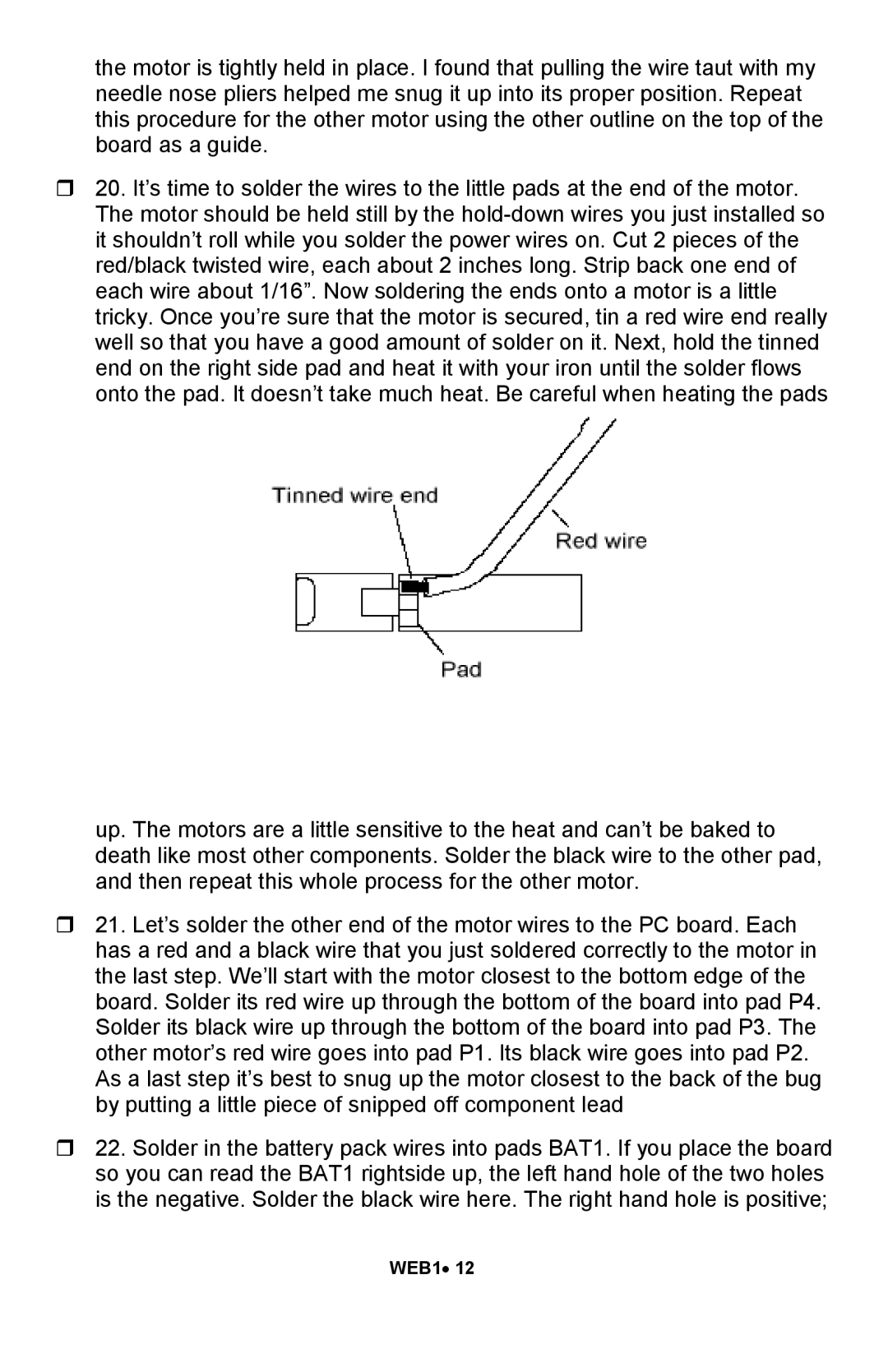

20. It’s time to solder the wires to the little pads at the end of the motor. The motor should be held still by the

up. The motors are a little sensitive to the heat and can’t be baked to death like most other components. Solder the black wire to the other pad, and then repeat this whole process for the other motor.

21. Let’s solder the other end of the motor wires to the PC board. Each has a red and a black wire that you just soldered correctly to the motor in the last step. We’ll start with the motor closest to the bottom edge of the board. Solder its red wire up through the bottom of the board into pad P4. Solder its black wire up through the bottom of the board into pad P3. The other motor’s red wire goes into pad P1. Its black wire goes into pad P2. As a last step it’s best to snug up the motor closest to the back of the bug by putting a little piece of snipped off component lead

22. Solder in the battery pack wires into pads BAT1. If you place the board so you can read the BAT1 rightside up, the left hand hole of the two holes is the negative. Solder the black wire here. The right hand hole is positive;