Models | X |

|

|

7.0″ | |

|

|

13.20″ | |

|

|

LEFT SIDE

Fig. 3: Component Locations — Hi Delta

NOTE: If a “DIP” switch is provided on the control

PCB, verify that the switch settings are correct: 1 = OFF, 2 = ON, 3 = OFF.

OPERATION

Verify the following upon a CALL FOR HEAT signal from the heater:

1.CALL FOR HEAT LED on PCB illuminates GREEN.

2.START UP MODE LED on PCB illuminates YEL- LOW. Before 7 minutes it should go out if boiler inlet temperature is approaching the set point tem- perature.

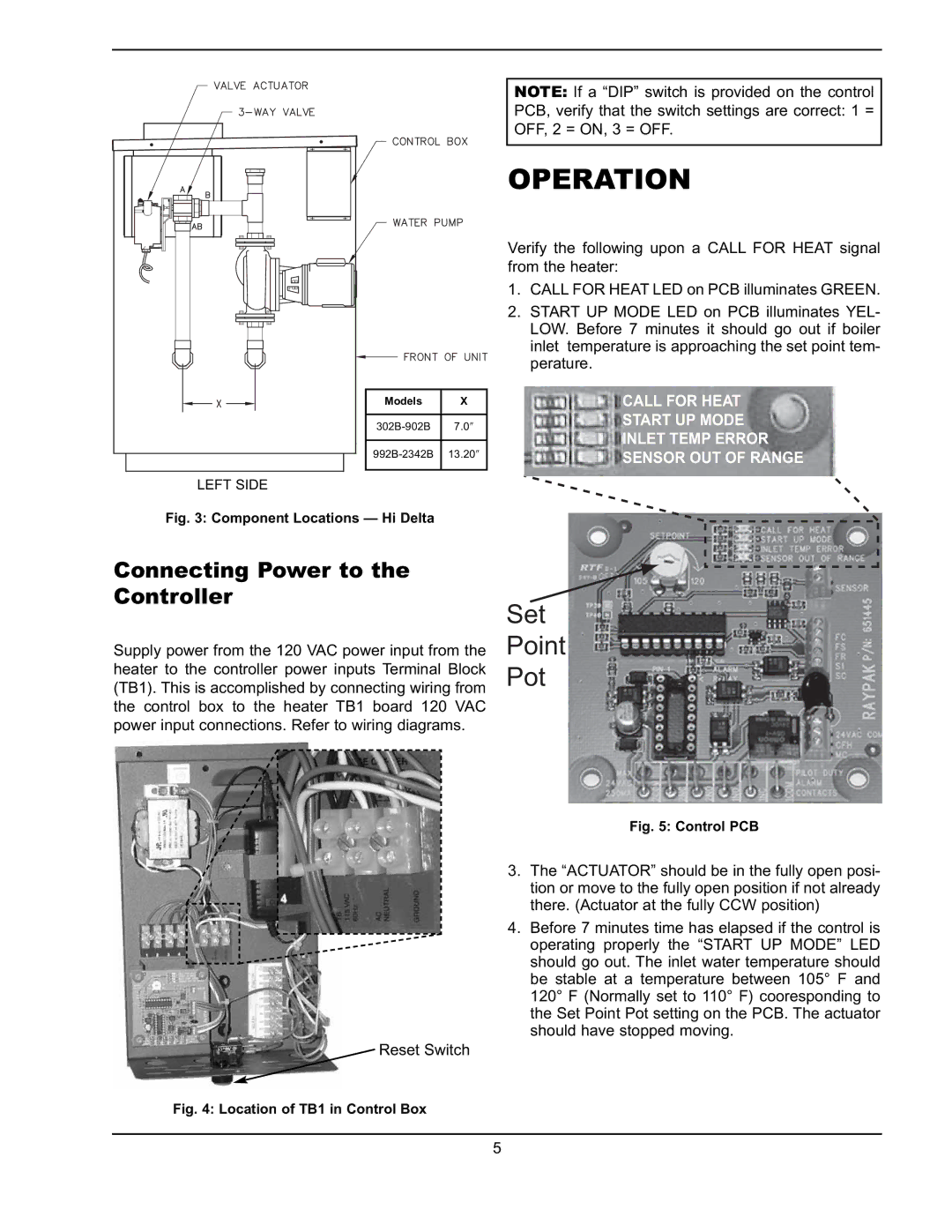

CALL FOR HEAT

START UP MODE

INLET TEMP ERROR

SENSOR OUT OF RANGE

Connecting Power to the Controller

Supply power from the 120 VAC power input from the heater to the controller power inputs Terminal Block (TB1). This is accomplished by connecting wiring from the control box to the heater TB1 board 120 VAC power input connections. Refer to wiring diagrams.

Set

Point

Pot

Fig. 5: Control PCB

3.The “ACTUATOR” should be in the fully open posi- tion or move to the fully open position if not already

there. (Actuator at the fully CCW position)

4.Before 7 minutes time has elapsed if the control is operating properly the “START UP MODE” LED

should go out. The inlet water temperature should be stable at a temperature between 105° F and 120° F (Normally set to 110° F) cooresponding to the Set Point Pot setting on the PCB. The actuator should have stopped moving.

![]() Reset Switch

Reset Switch

Fig. 4: Location of TB1 in Control Box

5