PSZ2460S

9. Maintenance

■SAW CHAIN

![]() WARNING

WARNING

It is very important for smooth and safe operation to keep the cutters always sharp.

Your cutters need to be sharpened when:

•Sawdust becomes

•You need extra force to saw in.

•The cut way does not go straight.

•Vibration increases.

•Fuel consumption increases.

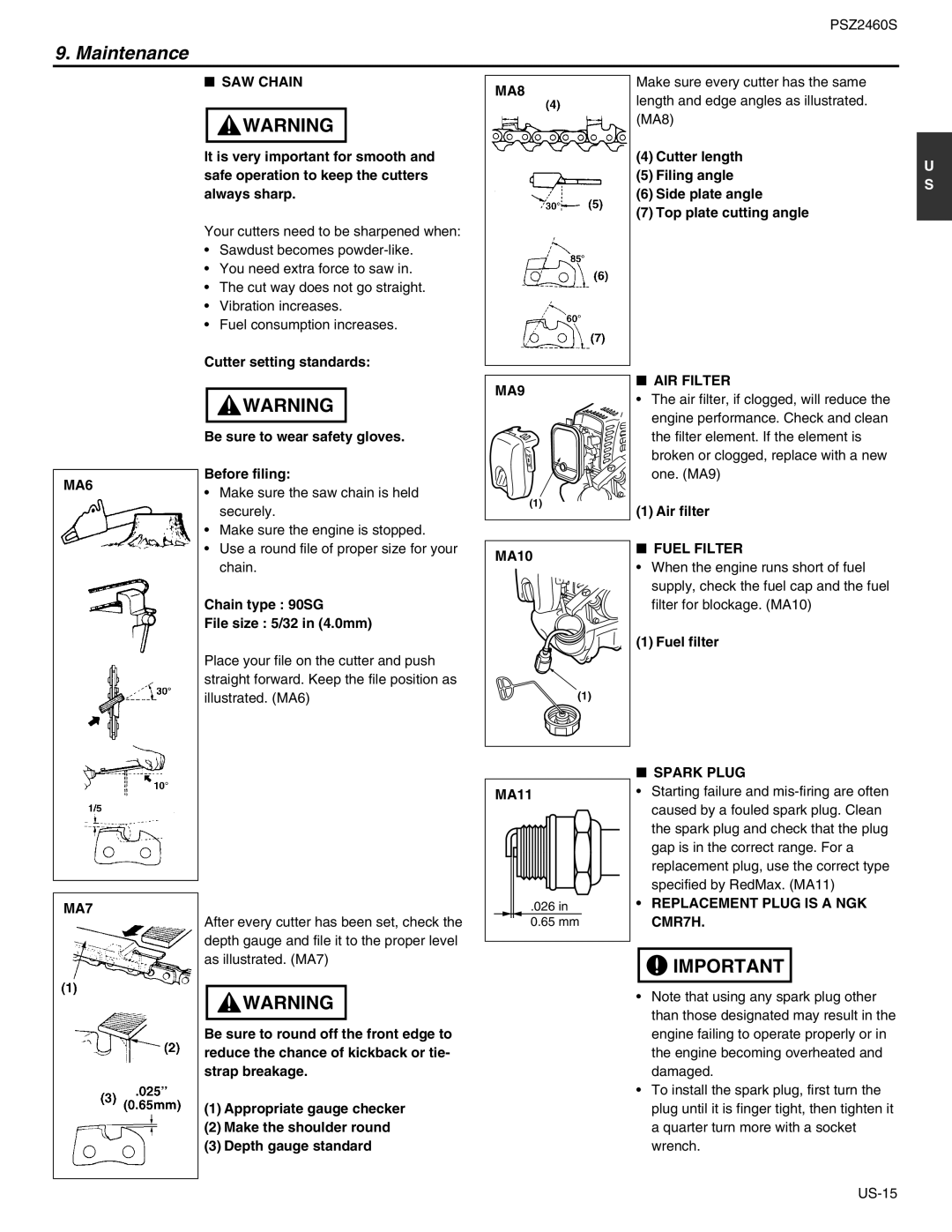

Cutter setting standards:

MA8 | Make sure every cutter has the same | ||

length and edge angles as illustrated. | |||

| |||

| (MA8) | ||

|

| ||

| (4) Cutter length | U | |

| (5) Filing angle | ||

| S | ||

| (6) Side plate angle | ||

|

| ||

| (7) Top plate cutting angle |

| |

|

|

| |

MA6

![]() WARNING

WARNING

Be sure to wear safety gloves.

Before filing:

• Make sure the saw chain is held |

MA9

■ AIR FILTER

• The air filter, if clogged, will reduce the engine performance. Check and clean the filter element. If the element is broken or clogged, replace with a new one. (MA9)

securely. |

• Make sure the engine is stopped. |

(1)

(1) Air filter

• Use a round file of proper size for your |

chain. |

Chain type : 90SG

File size : 5/32 in (4.0mm)

Place your file on the cutter and push straight forward. Keep the file position as illustrated. (MA6)

MA10 |

(1) |

■FUEL FILTER

•When the engine runs short of fuel supply, check the fuel cap and the fuel filter for blockage. (MA10)

(1) Fuel filter

MA7

After every cutter has been set, check the depth gauge and file it to the proper level

MA11 |

.026 in |

0.65 mm |

■SPARK PLUG

•Starting failure and

•REPLACEMENT PLUG IS A NGK CMR7H.

as illustrated. (MA7)

![]() WARNING

WARNING

Be sure to round off the front edge to reduce the chance of kickback or tie- strap breakage.

(1)Appropriate gauge checker

(2)Make the shoulder round

(3)Depth gauge standard

![]()

![]() IMPORTANT

IMPORTANT

•Note that using any spark plug other than those designated may result in the engine failing to operate properly or in the engine becoming overheated and damaged.

•To install the spark plug, first turn the plug until it is finger tight, then tighten it a quarter turn more with a socket wrench.