INSTALLATION

The Regency Insert incorporates its own inter- nal draft hood, so no additional external draft hood is required. Periodically check that the vent is unrestricted and an adequate draft is present when the

unit is in operation. (See page 9 for

spillage test.)

Natural Gas: | 3/16" open |

Propane: | 1/2" open |

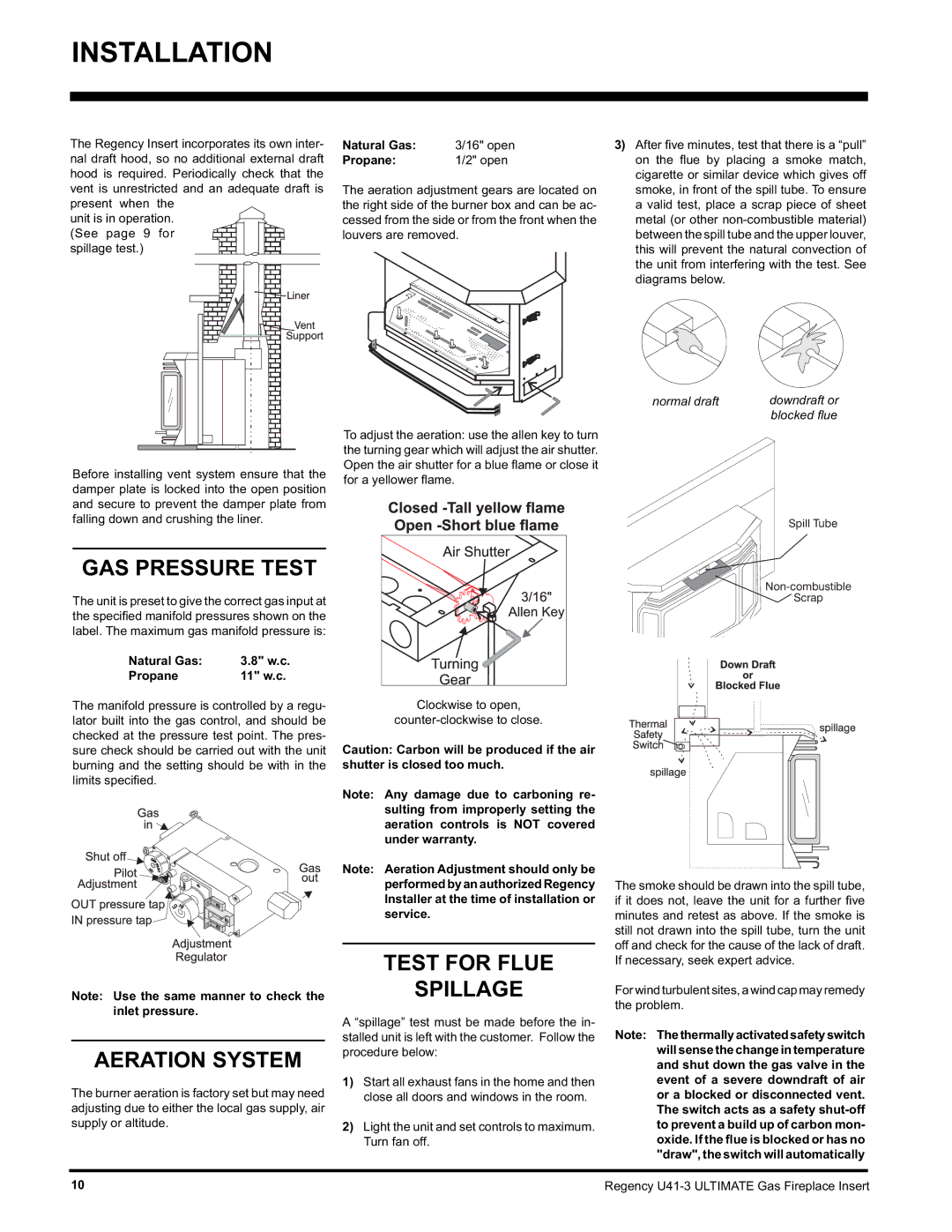

The aeration adjustment gears are located on the right side of the burner box and can be ac- cessed from the side or from the front when the louvers are removed.

3)After fi ve minutes, test that there is a “pull” on the fl ue by placing a smoke match, cigarette or similar device which gives off smoke, in front of the spill tube. To ensure a valid test, place a scrap piece of sheet metal (or other

Before installing vent system ensure that the damper plate is locked into the open position and secure to prevent the damper plate from falling down and crushing the liner.

GAS PRESSURE TEST

The unit is preset to give the correct gas input at the specifi ed manifold pressures shown on the label. The maximum gas manifold pressure is:

Natural Gas: | 3.8" w.c. |

Propane | 11" w.c. |

normal draft

To adjust the aeration: use the allen key to turn the turning gear which will adjust the air shutter. Open the air shutter for a blue fl ame or close it for a yellower fl ame.

downdraft or blocked fl ue

Spill Tube

Scrap

The manifold pressure is controlled by a regu- lator built into the gas control, and should be checked at the pressure test point. The pres- sure check should be carried out with the unit burning and the setting should be with in the limits specifi ed.

Note: Use the same manner to check the inlet pressure.

AERATION SYSTEM

The burner aeration is factory set but may need adjusting due to either the local gas supply, air supply or altitude.

Clockwise to open,

Caution: Carbon will be produced if the air shutter is closed too much.

Note: Any damage due to carboning re- sulting from improperly setting the aeration controls is NOT covered under warranty.

Note: Aeration Adjustment should only be performed by an authorized Regency Installer at the time of installation or service.

TEST FOR FLUE

SPILLAGE

A “spillage” test must be made before the in- stalled unit is left with the customer. Follow the procedure below:

1)Start all exhaust fans in the home and then close all doors and windows in the room.

2)Light the unit and set controls to maximum. Turn fan off.

The smoke should be drawn into the spill tube, if it does not, leave the unit for a further fi ve minutes and retest as above. If the smoke is still not drawn into the spill tube, turn the unit off and check for the cause of the lack of draft. If necessary, seek expert advice.

For wind turbulent sites, a wind cap may remedy the problem.

Note: Thethermallyactivatedsafetyswitch will sense the change in temperature and shut down the gas valve in the event of a severe downdraft of air or a blocked or disconnected vent. The switch acts as a safety

10 | Regency |