INSTALLATION

GAS CONNECTION

For minimum and maximum supply pressure see the System Data table on page 7.

Note: Prior to any pressure testing of the gas supply piping system that ex- ceeds test pressures of 1/2 psig, this appliance and its individual

Valve Access: Loosen and remove the wing- nuts on the both sides of the bottom louver and then remove the louver.

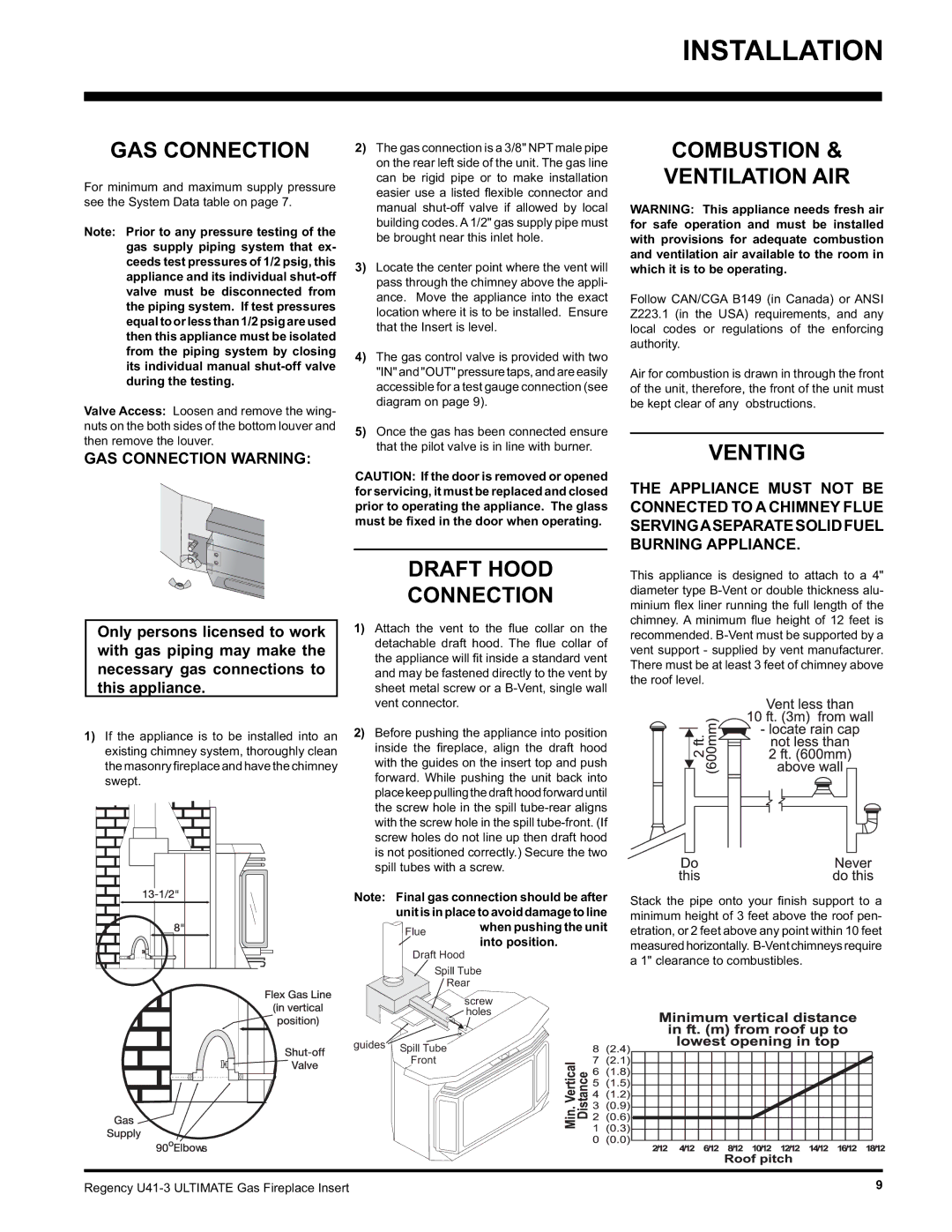

GAS CONNECTION WARNING:

2)The gas connection is a 3/8" NPT male pipe on the rear left side of the unit. The gas line can be rigid pipe or to make installation easier use a listed fl exible connector and manual

3)Locate the center point where the vent will pass through the chimney above the appli- ance. Move the appliance into the exact location where it is to be installed. Ensure that the Insert is level.

4)The gas control valve is provided with two "IN" and "OUT" pressure taps, and are easily accessible for a test gauge connection (see diagram on page 9).

5)Once the gas has been connected ensure that the pilot valve is in line with burner.

CAUTION: If the door is removed or opened for servicing, it must be replaced and closed prior to operating the appliance. The glass must be fixed in the door when operating.

DRAFT HOOD

CONNECTION

COMBUSTION &

VENTILATION AIR

WARNING: This appliance needs fresh air for safe operation and must be installed with provisions for adequate combustion and ventilation air available to the room in which it is to be operating.

Follow CAN/CGA B149 (in Canada) or ANSI Z223.1 (in the USA) requirements, and any local codes or regulations of the enforcing authority.

Air for combustion is drawn in through the front of the unit, therefore, the front of the unit must be kept clear of any obstructions.

VENTING

THE APPLIANCE MUST NOT BE CONNECTED TO A CHIMNEY FLUE SERVINGASEPARATESOLIDFUEL BURNING APPLIANCE.

This appliance is designed to attach to a 4" diameter type

Only persons licensed to work with gas piping may make the necessary gas connections to this appliance.

1)If the appliance is to be installed into an existing chimney system, thoroughly clean the masonry fireplace and have the chimney swept.

1)Attach the vent to the fl ue collar on the detachable draft hood. The fl ue collar of the appliance will fi t inside a standard vent and may be fastened directly to the vent by sheet metal screw or a

2)Before pushing the appliance into position inside the fi replace, align the draft hood with the guides on the insert top and push forward. While pushing the unit back into placekeeppullingthedrafthoodforwarduntil the screw hole in the spill

Note: Final gas connection should be after unit is in place to avoid damage to line

Flue | when pushing the unit |

Draft Hood | into position. |

|

Spill Tube

Rear

screw |

holes |

guides | Spill Tube |

| |

| Front |

recommended.

Stack the pipe onto your fi nish support to a minimum height of 3 feet above the roof pen- etration, or 2 feet above any point within 10 feet measuredhorizontally.

Regency | 9 |