®

ELECTRIC CHAIN SAW

ASSEMBLY

Note: Some models are pre assembled. As- sembly is not needed on these models.

See Saw Chain Tension Adjustment, page 7.

![]() WARNING: Cutting edges on chain are sharp. Use protective gloves when handling chain.

WARNING: Cutting edges on chain are sharp. Use protective gloves when handling chain.

IMPORTANT: Do not clamp chain saw in vise during assembly.

The plastic hardware bag should include:

•two guide bar bolts

•two guide bar nuts

•one

•automatic chain sharpener (Fast Sharp models only)

1.Lay chain out flat.

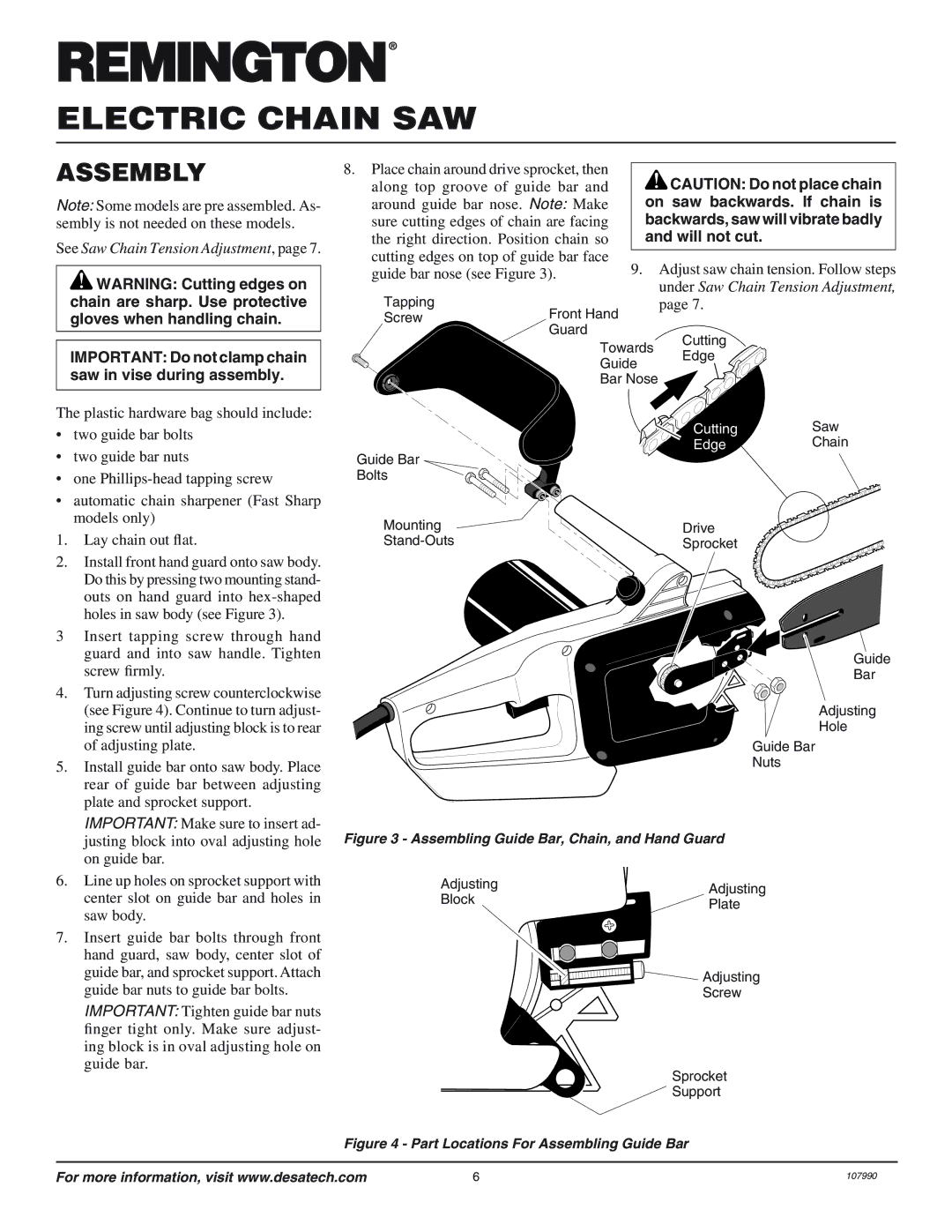

2.Install front hand guard onto saw body. Do this by pressing two mounting stand- outs on hand guard into

3Insert tapping screw through hand guard and into saw handle. Tighten screw firmly.

4.Turn adjusting screw counterclockwise (see Figure 4). Continue to turn adjust- ing screw until adjusting block is to rear of adjusting plate.

5.Install guide bar onto saw body. Place rear of guide bar between adjusting plate and sprocket support.

IMPORTANT: Make sure to insert ad- justing block into oval adjusting hole on guide bar.

6.Line up holes on sprocket support with center slot on guide bar and holes in saw body.

7.Insert guide bar bolts through front hand guard, saw body, center slot of guide bar, and sprocket support. Attach guide bar nuts to guide bar bolts.

IMPORTANT: Tighten guide bar nuts finger tight only. Make sure adjust- ing block is in oval adjusting hole on guide bar.

8. Place chain around drive sprocket, then |

|

| CAUTION: Do not place chain | ||

along top groove of guide bar and |

|

| |||

around guide bar nose. Note: Make |

| on saw backwards. If chain is | |||

sure cutting edges of chain are facing |

| backwards, saw will vibrate badly | |||

the right direction. Position chain so |

| and will not cut. |

| ||

cutting edges on top of guide bar face | 9. |

| Adjust saw chain tension. Follow steps | ||

guide bar nose (see Figure 3). |

| ||||

|

| under Saw Chain Tension Adjustment, | |||

Tapping |

|

|

| ||

Front Hand |

|

| page 7. |

| |

Screw |

|

|

|

| |

| Guard |

|

| Cutting |

|

| Towards |

| |||

| Edge |

| |||

| Guide |

|

| ||

|

|

|

| ||

| Bar Nose |

|

| ||

|

|

|

| Cutting | Saw |

Guide Bar |

|

|

| Edge | Chain |

|

|

|

|

| |

Bolts |

|

|

|

|

|

Mounting |

|

|

| Drive |

|

|

|

| Sprocket |

| |

Guide

Bar

Adjusting

Hole

Guide Bar

Nuts

Figure 3 - Assembling Guide Bar, Chain, and Hand Guard

Adjusting | Adjusting | |

Block | ||

Plate | ||

|

Adjusting

Screw

Sprocket

Support

Figure 4 - Part Locations For Assembling Guide Bar

For more information, visit www.desatech.com | 6 | 107990 |