OPERATION

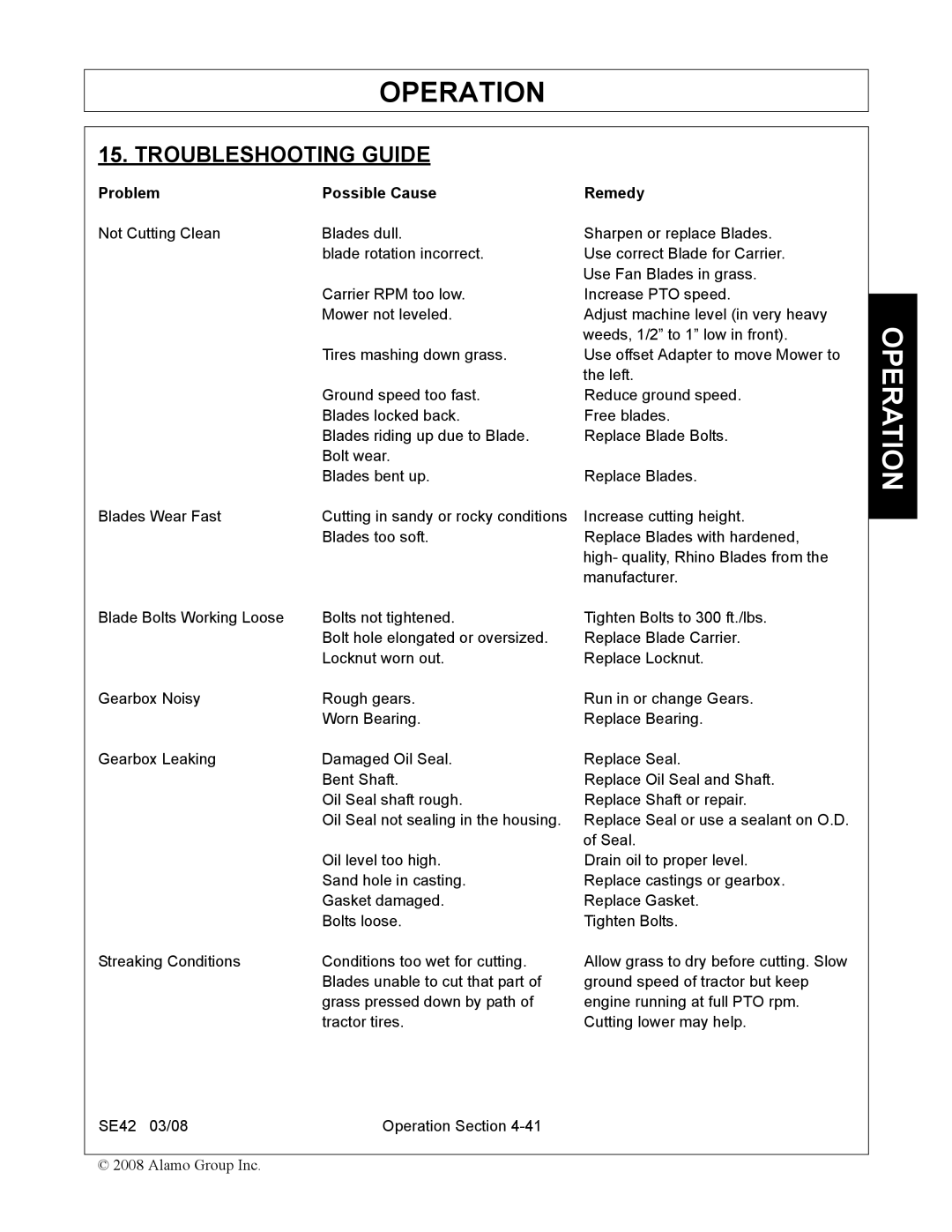

15. TROUBLESHOOTING GUIDE

Problem | Possible Cause | Remedy |

Not Cutting Clean | Blades dull. | Sharpen or replace Blades. |

| blade rotation incorrect. | Use correct Blade for Carrier. |

|

| Use Fan Blades in grass. |

| Carrier RPM too low. | Increase PTO speed. |

| Mower not leveled. | Adjust machine level (in very heavy |

|

| weeds, 1/2” to 1” low in front). |

| Tires mashing down grass. | Use offset Adapter to move Mower to |

|

| the left. |

| Ground speed too fast. | Reduce ground speed. |

| Blades locked back. | Free blades. |

| Blades riding up due to Blade. | Replace Blade Bolts. |

| Bolt wear. |

|

| Blades bent up. | Replace Blades. |

Blades Wear Fast | Cutting in sandy or rocky conditions | Increase cutting height. |

| Blades too soft. | Replace Blades with hardened, |

|

| high- quality, Rhino Blades from the |

|

| manufacturer. |

OPERATION

Blade Bolts Working Loose | Bolts not tightened. |

| Bolt hole elongated or oversized. |

| Locknut worn out. |

Gearbox Noisy | Rough gears. |

| Worn Bearing. |

Gearbox Leaking | Damaged Oil Seal. |

| Bent Shaft. |

| Oil Seal shaft rough. |

| Oil Seal not sealing in the housing. |

| Oil level too high. |

| Sand hole in casting. |

| Gasket damaged. |

| Bolts loose. |

Streaking Conditions | Conditions too wet for cutting. |

| Blades unable to cut that part of |

| grass pressed down by path of |

| tractor tires. |

Tighten Bolts to 300 ft./lbs.

Replace Blade Carrier.

Replace Locknut.

Run in or change Gears.

Replace Bearing.

Replace Seal.

Replace Oil Seal and Shaft. Replace Shaft or repair.

Replace Seal or use a sealant on O.D. of Seal.

Drain oil to proper level. Replace castings or gearbox. Replace Gasket.

Tighten Bolts.

Allow grass to dry before cutting. Slow ground speed of tractor but keep engine running at full PTO rpm. Cutting lower may help.

SE42 03/08 | Operation Section |

© 2008 Alamo Group Inc.