MS1250LZA specifications

The RIDGID MS1250LZA is a versatile and robust miter saw designed for professionals and DIY enthusiasts alike. This powerful tool is engineered to deliver precision cutting for a wide range of materials, including wood, plastic, and light metals, making it an ideal choice for carpenters, contractors, and hobbyists.One of the standout features of the MS1250LZA is its impressive 15-amp motor, which provides ample power to handle tough cutting tasks with ease. The motor is capable of reaching up to 5000 RPM, ensuring clean and accurate cuts every time. Whether you are making crosscuts, miters, or bevel cuts, this saw can handle it all with precision and efficiency.

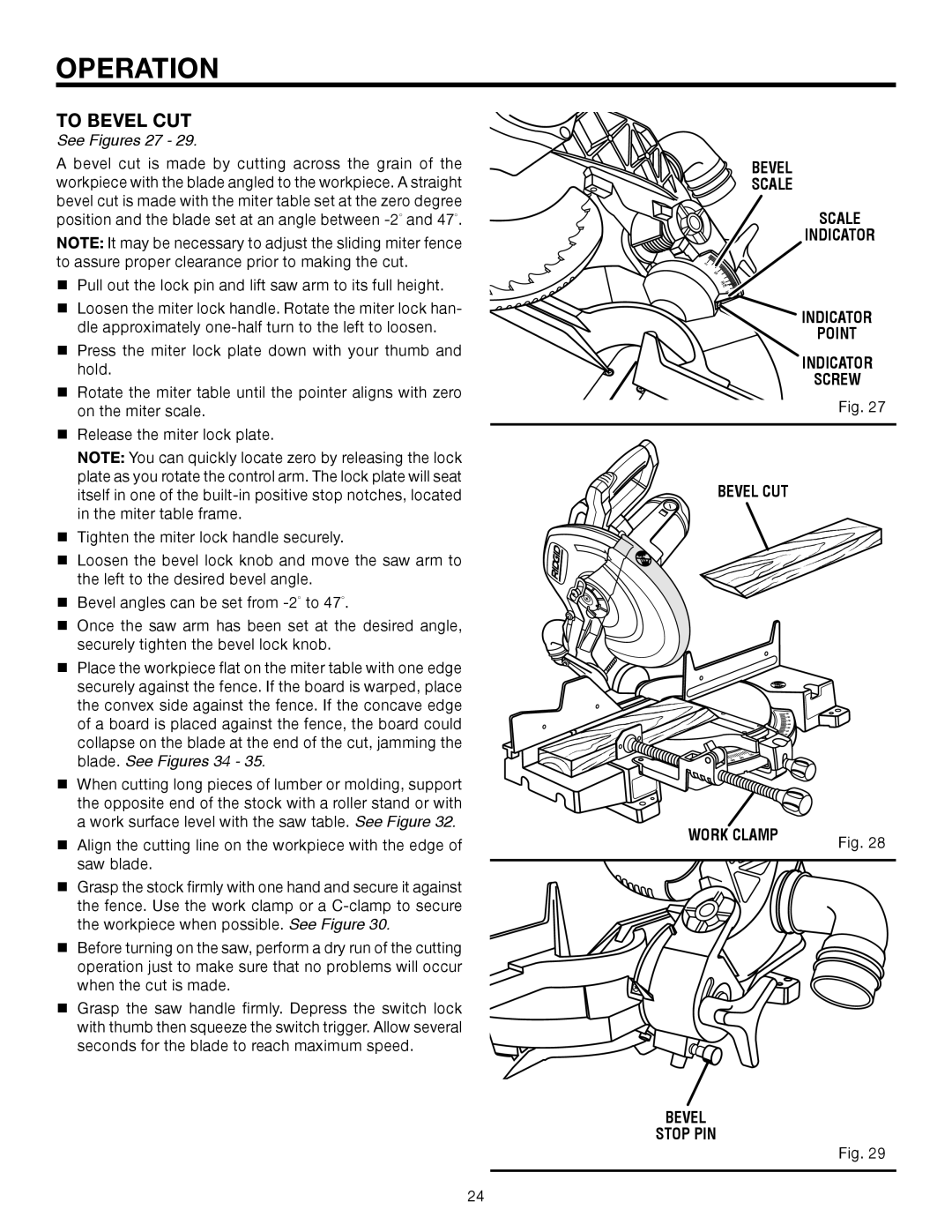

The MS1250LZA incorporates a dual bevel design, allowing for both left and right angles of bevel cuts. This flexibility enhances the saw's usability, enabling users to create compound cuts without needing to flip the workpiece, which saves time and increases accuracy. The intuitive bevel adjustment lever allows for quick and straightforward adjustments, ensuring that you can easily switch between angles as needed.

Another significant technological advancement in the MS1250LZA is the laser guide system. This feature projects a clear, precise line on the cutting surface, providing enhanced visibility and accuracy. Users can easily line up their cuts without the guesswork, making it especially beneficial for intricate projects or when working with small pieces.

The saw's sliding feature is also noteworthy, as it allows for larger cuts with ease. The sliding arm can handle wider materials, making it perfect for framing lumber, larger boards, or even plywood sheets. Additionally, the positive stops on the miter table provide easy access to commonly used angles, streamlining the workflow for repetitive cuts.

Safety is paramount in any power tool, and the RIDGID MS1250LZA includes several safety features that protect both the user and the workpiece. The electric brake stops the blade quickly after the trigger is released, minimizing the risk of accidents. A transparent blade guard allows users to see the cutting area while keeping hands and fingers safe from the blade.

In terms of portability, the MS1250LZA is relatively lightweight and features a sturdy carrying handle, making it easy to transport between job sites. The durable construction ensures that it can withstand the rigors of professional use while delivering reliable performance over time.

Overall, the RIDGID MS1250LZA miter saw presents an impressive combination of power, flexibility, and safety features, making it an indispensable tool for any serious woodworking or construction project. With its user-friendly design and high-performance capabilities, it is sure to enhance the productivity and efficiency of its users.