OPERATION

INSTALLING DEPTH GAUGE ROD

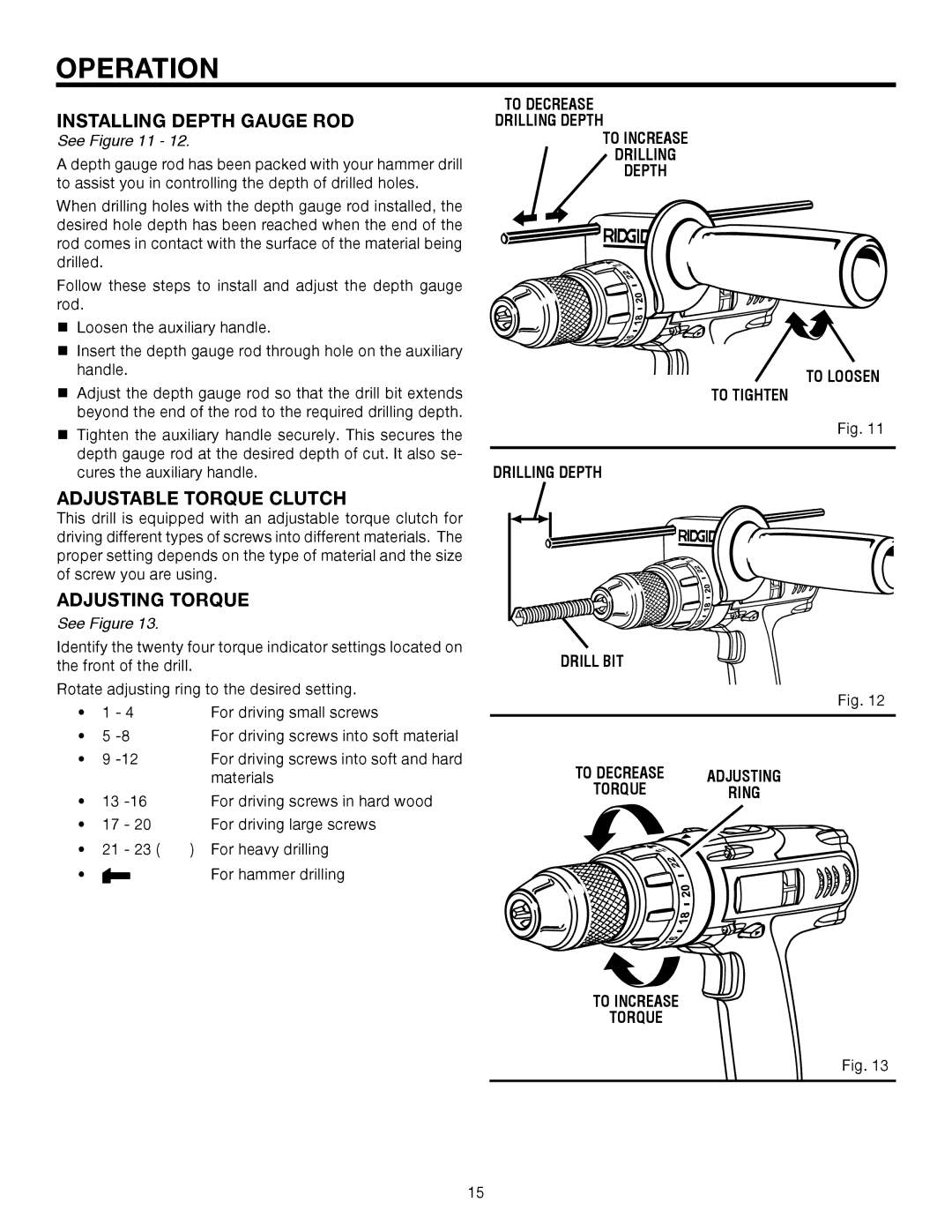

See Figure 11 - 12.

A depth gauge rod has been packed with your hammer drill to assist you in controlling the depth of drilled holes.

When drilling holes with the depth gauge rod installed, the desired hole depth has been reached when the end of the rod comes in contact with the surface of the material being drilled.

Follow these steps to install and adjust the depth gauge rod.

nLoosen the auxiliary handle.

nInsert the depth gauge rod through hole on the auxiliary handle.

nAdjust the depth gauge rod so that the drill bit extends beyond the end of the rod to the required drilling depth.

nTighten the auxiliary handle securely. This secures the depth gauge rod at the desired depth of cut. It also se- cures the auxiliary handle.

ADJUSTABLE TORQUE CLUTCH

This drill is equipped with an adjustable torque clutch for driving different types of screws into different materials. The proper setting depends on the type of material and the size of screw you are using.

ADJUSTING TORQUE

See Figure 13.

�Identify the twenty four torque indicator settings located on the front of the drill.

�Rotate adjusting ring to the desired setting.

• | 1 | - 4 | For driving small screws | |

• | 5 | For driving screws into soft material | ||

• | 9 | For driving screws into soft and hard | ||

|

|

|

| materials |

• | 13 | For driving screws in hard wood | ||

• | 17 | - 20 | For driving large screws | |

•21 - 23 (![]() ) For heavy drilling

) For heavy drilling

• | For hammer drilling |

TO DECREASE

DRILLING DEPTH

TO INCREASE

DRILLING

DEPTH

TO LOOSEN

TO TIGHTEN

Fig. 11

DRILLING DEPTH

DRILL BIT

Fig. 12

TO DECREASE | ADJUSTING |

TORQUE | RING |

TO INCREASE

TORQUE

Fig. 13

15