Maintenance

Maintenance

![]() WARNING: For your own safety, turn switch OFF (O) and remove plug from power source outlet before maintaining or lubricating your drill press.

WARNING: For your own safety, turn switch OFF (O) and remove plug from power source outlet before maintaining or lubricating your drill press.

A coat of automotive type paste wax applied to the table and column will help to keep the surfaces clean.

Lubrication

All of the ball bearings are packed with grease at the factory. They require no fur- ther lubrication.

Periodically lubricate the table elevation mechanism, the splines (grooves) in the spindle, and the rack (teeth of the quill). See “Getting to Know Your Drill Press”.

![]() WARNING: To reduce the risk of shock or fire hazard, if the power cord is worn or cut, or damaged in any way, have it replaced immedi- ately.

WARNING: To reduce the risk of shock or fire hazard, if the power cord is worn or cut, or damaged in any way, have it replaced immedi- ately.

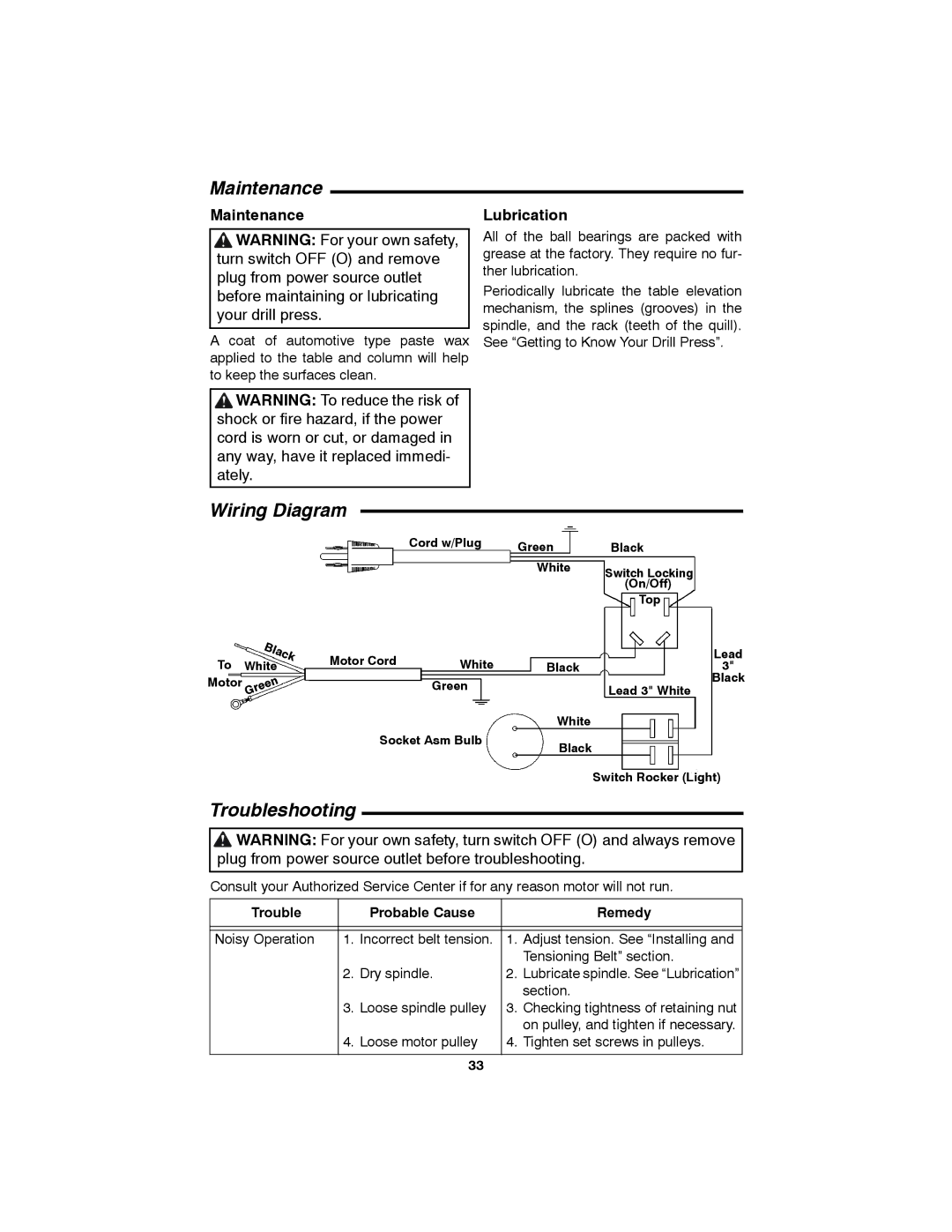

Wiring Diagram

To

Motor

|

| Bl |

| |

|

|

| a | |

White | ck | |||

| ||||

|

|

| n |

|

|

| e |

| |

| e |

|

| |

r |

|

|

| |

G |

|

|

|

|

| Cord w/Plug | Green | Black |

|

| ||

|

| White | Switch Locking |

|

|

| |

|

|

| (On/Off) |

|

|

| Top |

Motor Cord | White |

| Lead |

Black | 3" | ||

|

|

| Black |

Green | Lead 3" White |

| |

| White |

Socket Asm Bulb | Black |

| |

| Switch Rocker (Light) |

Troubleshooting

![]() WARNING: For your own safety, turn switch OFF (O) and always remove plug from power source outlet before troubleshooting.

WARNING: For your own safety, turn switch OFF (O) and always remove plug from power source outlet before troubleshooting.

Consult your Authorized Service Center if for any reason motor will not run.

Trouble |

| Probable Cause |

| Remedy |

|

|

|

| |

|

|

|

| |

Noisy Operation | 1. Incorrect belt tension. | 1. | Adjust tension. See “Installing and | |

|

|

|

| Tensioning Belt” section. |

| 2. | Dry spindle. | 2. | Lubricate spindle. See “Lubrication” |

|

|

|

| section. |

| 3. | Loose spindle pulley | 3. | Checking tightness of retaining nut |

|

|

|

| on pulley, and tighten if necessary. |

| 4. | Loose motor pulley | 4. | Tighten set screws in pulleys. |

|

|

|

|

|

33