14.4 Wheel Removal | Section 14 Page 2 of 2 |

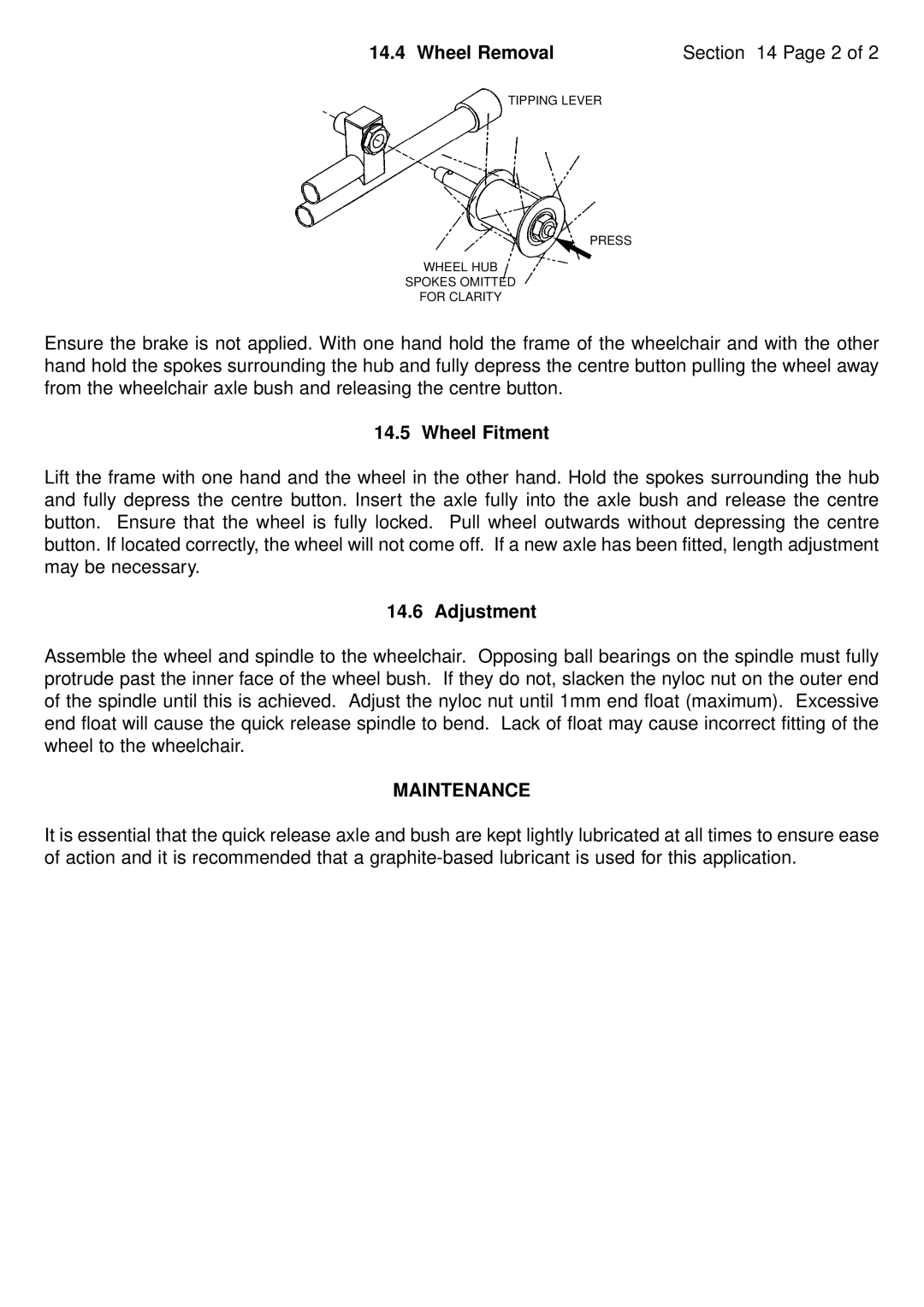

TIPPING LEVER |

|

PRESS

WHEEL HUB

SPOKES OMITTED

FOR CLARITY

Ensure the brake is not applied. With one hand hold the frame of the wheelchair and with the other hand hold the spokes surrounding the hub and fully depress the centre button pulling the wheel away from the wheelchair axle bush and releasing the centre button.

14.5 Wheel Fitment

Lift the frame with one hand and the wheel in the other hand. Hold the spokes surrounding the hub and fully depress the centre button. Insert the axle fully into the axle bush and release the centre button. Ensure that the wheel is fully locked. Pull wheel outwards without depressing the centre button. If located correctly, the wheel will not come off. If a new axle has been fitted, length adjustment may be necessary.

14.6 Adjustment

Assemble the wheel and spindle to the wheelchair. Opposing ball bearings on the spindle must fully protrude past the inner face of the wheel bush. If they do not, slacken the nyloc nut on the outer end of the spindle until this is achieved. Adjust the nyloc nut until 1mm end float (maximum). Excessive end float will cause the quick release spindle to bend. Lack of float may cause incorrect fitting of the wheel to the wheelchair.

MAINTENANCE

It is essential that the quick release axle and bush are kept lightly lubricated at all times to ensure ease of action and it is recommended that a