SECTION 3: INSTALLATION

SECTION 3: INSTALLATION

![]() DANGER

DANGER

Electrical Shock Hazard

Disconnect electric before service or maintenance.

Control must be connected to a properly grounded electrical source.

Failure to follow these instructions can result in death or electrical shock.

Installation of the System Control and the associated external electrical wiring must be completed by an electrician qualified in the installation of control systems for heating equipment.

3.1 Preparation

Before installing the System Control, observe the following:

3.1.1Ensure that you have a copy of the site layout for the project that identifies clearly the separate zones.

3.1.2Read Page 1, Section 1.4 carefully to ensure the correct installation materials are available.

3.2 Installing the System Control Panel

3.2.1Choose a mounting location for the System Control. It is advisable to choose a visible location near the pump.

Do not mount System Control outdoors or in an area with moisture spray, excessive moisture or humidity. To avoid damage from possible drips, do not mount controller directly beneath pump.

3.2.2Remove the cover of the System Control by removing the four securing screws.

3.2.3Place the cover and the hardware in a safe place for refitting after the external wiring connections have been made.

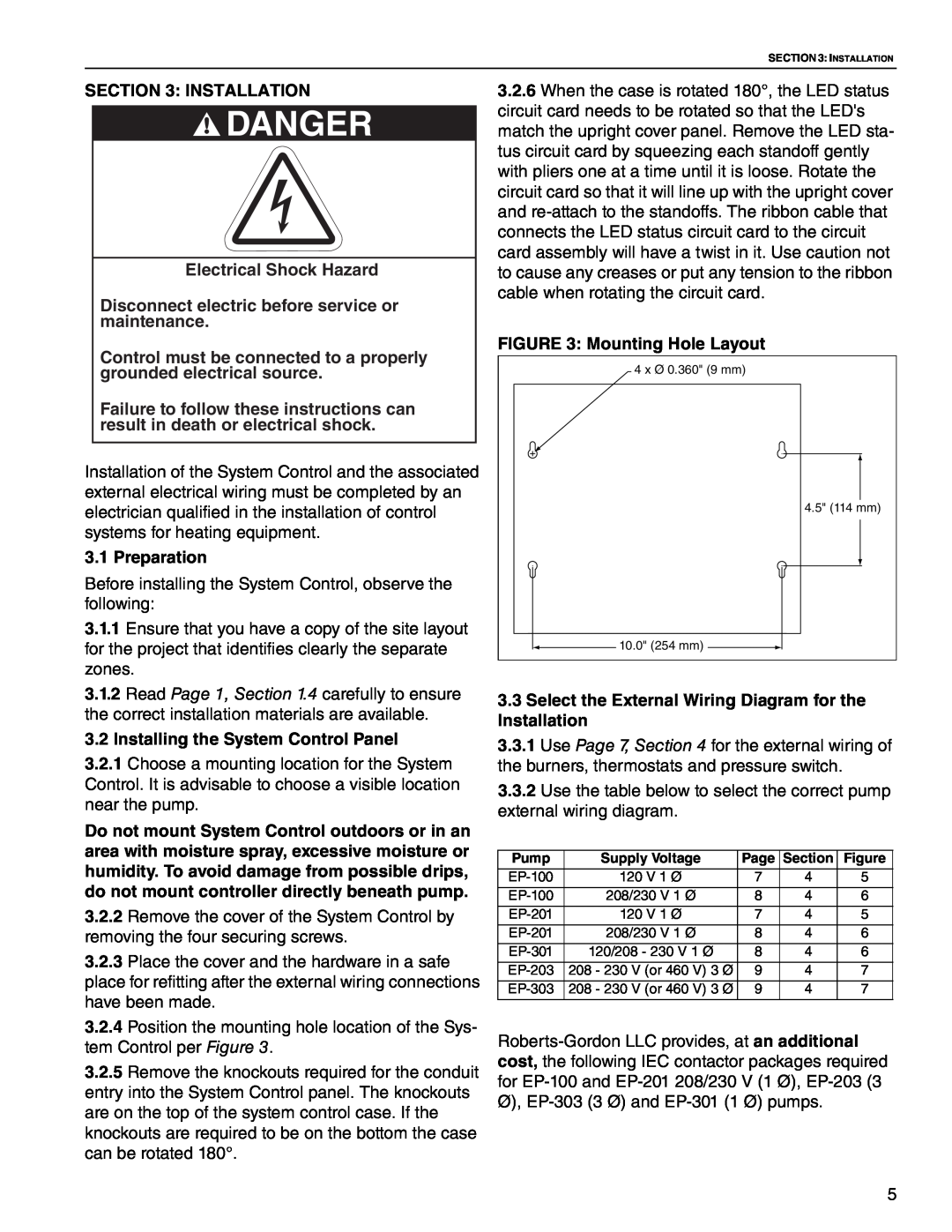

3.2.4Position the mounting hole location of the Sys- tem Control per Figure 3.

3.2.5Remove the knockouts required for the conduit entry into the System Control panel. The knockouts are on the top of the system control case. If the knockouts are required to be on the bottom the case can be rotated 180°.

3.2.6When the case is rotated 180°, the LED status circuit card needs to be rotated so that the LED's match the upright cover panel. Remove the LED sta- tus circuit card by squeezing each standoff gently with pliers one at a time until it is loose. Rotate the circuit card so that it will line up with the upright cover and

FIGURE 3: Mounting Hole Layout

4 x Ø 0.360" (9 mm) |

4.5" (114 mm) |

10.0" (254 mm) |

3.3Select the External Wiring Diagram for the Installation

3.3.1Use Page 7, Section 4 for the external wiring of the burners, thermostats and pressure switch.

3.3.2Use the table below to select the correct pump external wiring diagram.

Pump | Supply Voltage | Page | Section | Figure |

120 V 1 Ø | 7 | 4 | 5 | |

208/230 V 1 Ø | 8 | 4 | 6 | |

120 V 1 Ø | 7 | 4 | 5 | |

208/230 V 1 Ø | 8 | 4 | 6 | |

120/208 - 230 V 1 Ø | 8 | 4 | 6 | |

208 - 230 V (or 460 V) 3 Ø | 9 | 4 | 7 | |

208 - 230 V (or 460 V) 3 Ø | 9 | 4 | 7 |

5