OPERATION

![]() WARNING:

WARNING:

Always wear safety goggles or safety glasses with side shields when operating tools. Failure to do so could result in objects being thrown into your eyes, resulting in possible serious injury.

A variety of spline joints can be made using your biscuit joiner. The number and size biscuits needed for each joint depends on the thickness of the wood and the length of the joint. In general, the small #R1 biscuits should be used for miter cuts in small, thin materials. The larger biscuits should be used for

When joining thick materials, stack two biscuits, one above the other. For example, joining 2 in. x 4 in. dressed lumber. See Figure 9. When joining even thicker materials, use additional biscuits, stacked above each other.

When making

The following sections illustrate how to make various spline joints using your biscuit joiner.

EDGE-TO-EDGE JOINTS

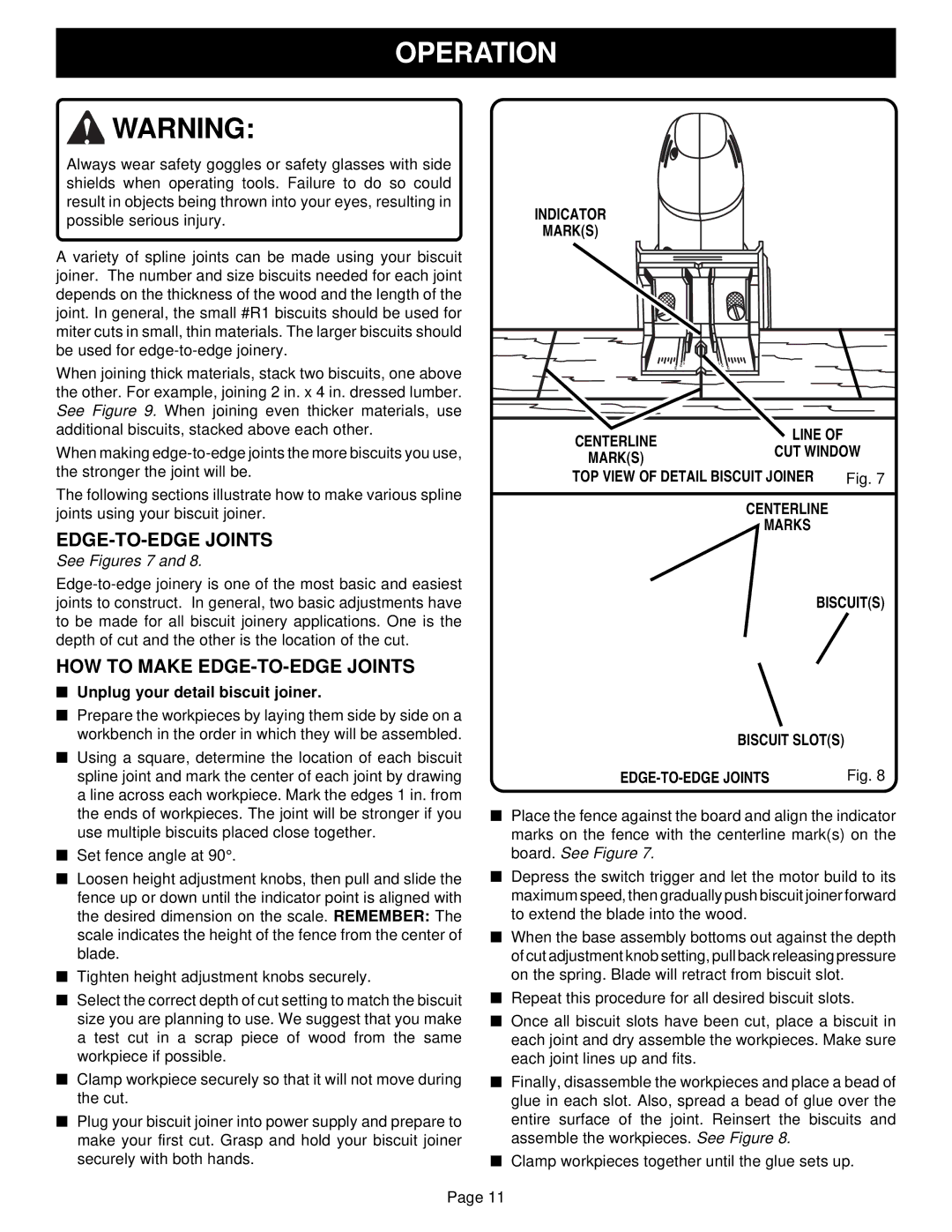

See Figures 7 and 8.

HOW TO MAKE EDGE-TO-EDGE JOINTS

■Unplug your detail biscuit joiner.

■Prepare the workpieces by laying them side by side on a workbench in the order in which they will be assembled.

■Using a square, determine the location of each biscuit spline joint and mark the center of each joint by drawing a line across each workpiece. Mark the edges 1 in. from the ends of workpieces. The joint will be stronger if you use multiple biscuits placed close together.

■Set fence angle at 90°.

■Loosen height adjustment knobs, then pull and slide the fence up or down until the indicator point is aligned with the desired dimension on the scale. REMEMBER: The scale indicates the height of the fence from the center of blade.

■Tighten height adjustment knobs securely.

■Select the correct depth of cut setting to match the biscuit size you are planning to use. We suggest that you make a test cut in a scrap piece of wood from the same workpiece if possible.

■Clamp workpiece securely so that it will not move during the cut.

■Plug your biscuit joiner into power supply and prepare to make your first cut. Grasp and hold your biscuit joiner securely with both hands.

INDICATOR

MARK(S)

| 2 | 1 | 1 |

|

3 |

| 2 | 3 |

CENTERLINE | LINE OF |

| |

CUT WINDOW | |||

MARK(S) | |||

|

| ||

TOP VIEW OF DETAIL BISCUIT JOINER | Fig. 7 | ||

|

|

| |

CENTERLINE

MARKS

MARKS

BISCUIT(S)

BISCUIT SLOT(S)

| Fig. 8 |

■Place the fence against the board and align the indicator marks on the fence with the centerline mark(s) on the board. See Figure 7.

■Depress the switch trigger and let the motor build to its maximum speed, then gradually push biscuit joiner forward to extend the blade into the wood.

■When the base assembly bottoms out against the depth of cut adjustment knob setting, pull back releasing pressure on the spring. Blade will retract from biscuit slot.

■Repeat this procedure for all desired biscuit slots.

■Once all biscuit slots have been cut, place a biscuit in each joint and dry assemble the workpieces. Make sure each joint lines up and fits.

■Finally, disassemble the workpieces and place a bead of glue in each slot. Also, spread a bead of glue over the entire surface of the joint. Reinsert the biscuits and assemble the workpieces. See Figure 8.

■Clamp workpieces together until the glue sets up.

Page 11