OPERATION

CHUCK REMOVAL

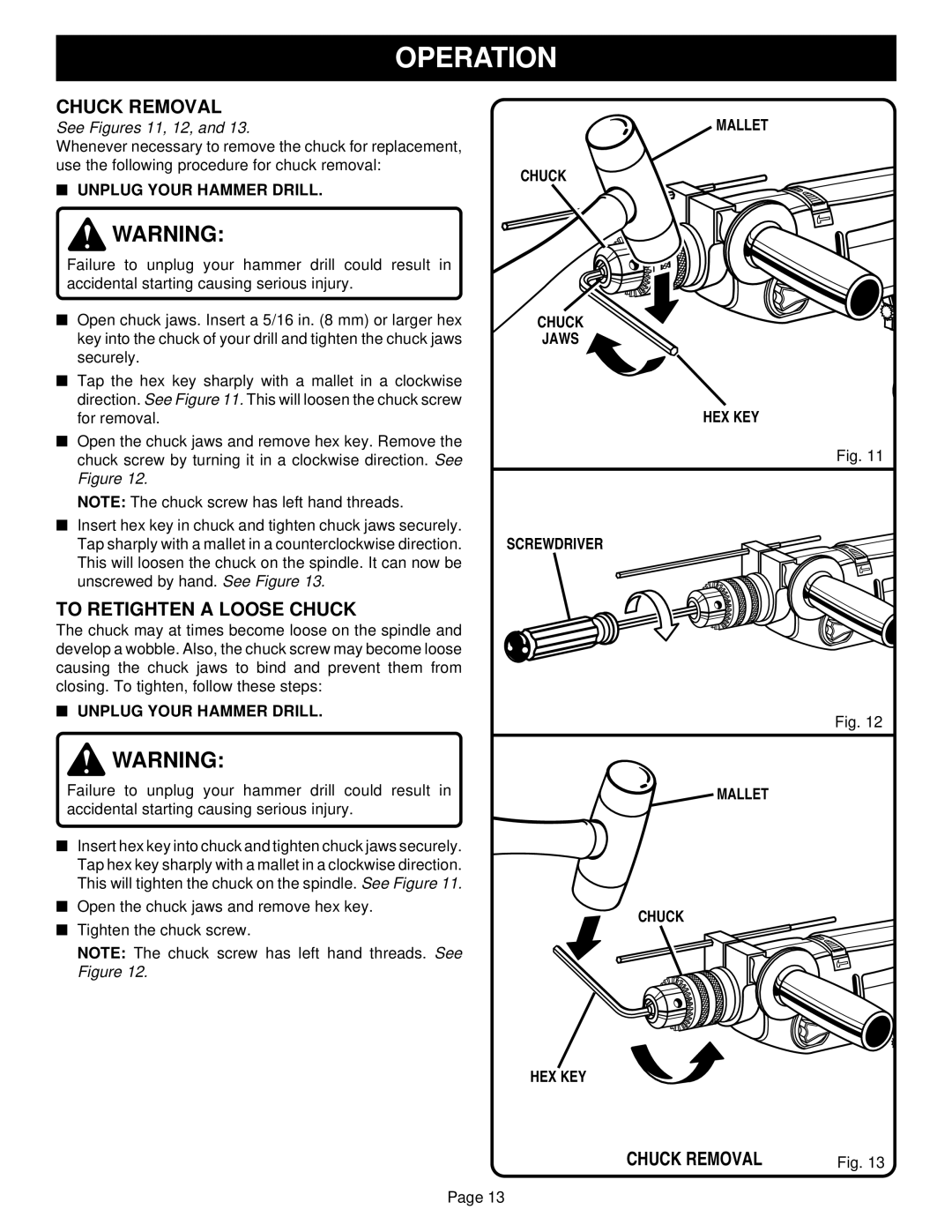

See Figures 11, 12, and 13.

Whenever necessary to remove the chuck for replacement, use the following procedure for chuck removal:

■UNPLUG YOUR HAMMER DRILL.

![]() WARNING:

WARNING:

Failure to unplug your hammer drill could result in accidental starting causing serious injury.

■Open chuck jaws. Insert a 5/16 in. (8 mm) or larger hex key into the chuck of your drill and tighten the chuck jaws securely.

■Tap the hex key sharply with a mallet in a clockwise direction. See Figure 11. This will loosen the chuck screw for removal.

■Open the chuck jaws and remove hex key. Remove the chuck screw by turning it in a clockwise direction. See Figure 12.

NOTE: The chuck screw has left hand threads.

■Insert hex key in chuck and tighten chuck jaws securely. Tap sharply with a mallet in a counterclockwise direction. This will loosen the chuck on the spindle. It can now be unscrewed by hand. See Figure 13.

TO RETIGHTEN A LOOSE CHUCK

The chuck may at times become loose on the spindle and develop a wobble. Also, the chuck screw may become loose causing the chuck jaws to bind and prevent them from closing. To tighten, follow these steps:

■UNPLUG YOUR HAMMER DRILL.

![]() WARNING:

WARNING:

Failure to unplug your hammer drill could result in accidental starting causing serious injury.

■Insert hex key into chuck and tighten chuck jaws securely. Tap hex key sharply with a mallet in a clockwise direction. This will tighten the chuck on the spindle. See Figure 11.

■Open the chuck jaws and remove hex key.

■Tighten the chuck screw.

NOTE: The chuck screw has left hand threads. See Figure 12.

MALLET

CHUCK

CHUCK

JAWS

HEX KEY

Fig. 11

SCREWDRIVER

Fig. 12

MALLET

CHUCK

HEX KEY

CHUCK REMOVAL | Fig. 13 |

Page 13