ELECTRICAL

EXTENSION CORDS | ELECTRICAL CONNECTION |

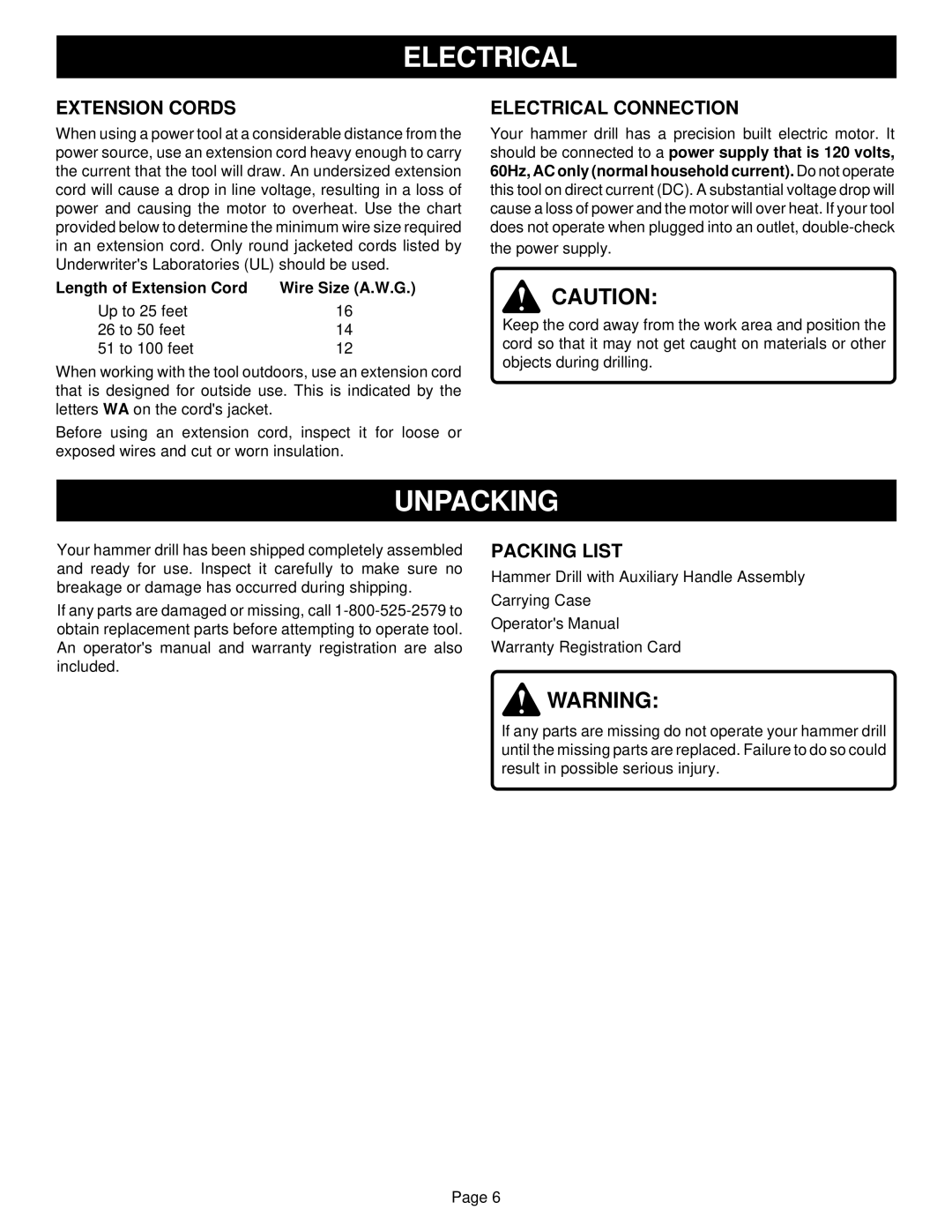

When using a power tool at a considerable distance from the power source, use an extension cord heavy enough to carry the current that the tool will draw. An undersized extension cord will cause a drop in line voltage, resulting in a loss of power and causing the motor to overheat. Use the chart provided below to determine the minimum wire size required in an extension cord. Only round jacketed cords listed by Underwriter's Laboratories (UL) should be used.

Your hammer drill has a precision built electric motor. It should be connected to a power supply that is 120 volts, 60Hz, AC only (normal household current). Do not operate this tool on direct current (DC). A substantial voltage drop will cause a loss of power and the motor will over heat. If your tool does not operate when plugged into an outlet,

Length of Extension Cord | Wire Size (A.W.G.) |

Up to 25 feet | 16 |

26 to 50 feet | 14 |

51 to 100 feet | 12 |

When working with the tool outdoors, use an extension cord that is designed for outside use. This is indicated by the letters WA on the cord's jacket.

Before using an extension cord, inspect it for loose or exposed wires and cut or worn insulation.

CAUTION:

Keep the cord away from the work area and position the cord so that it may not get caught on materials or other objects during drilling.

UNPACKING

Your hammer drill has been shipped completely assembled and ready for use. Inspect it carefully to make sure no breakage or damage has occurred during shipping.

If any parts are damaged or missing, call

PACKING LIST

Hammer Drill with Auxiliary Handle Assembly

Carrying Case

Operator's Manual

Warranty Registration Card

![]() WARNING:

WARNING:

If any parts are missing do not operate your hammer drill until the missing parts are replaced. Failure to do so could result in possible serious injury.

Page 6