OPERATION

ADJUSTABLE TORQUE CLUTCH

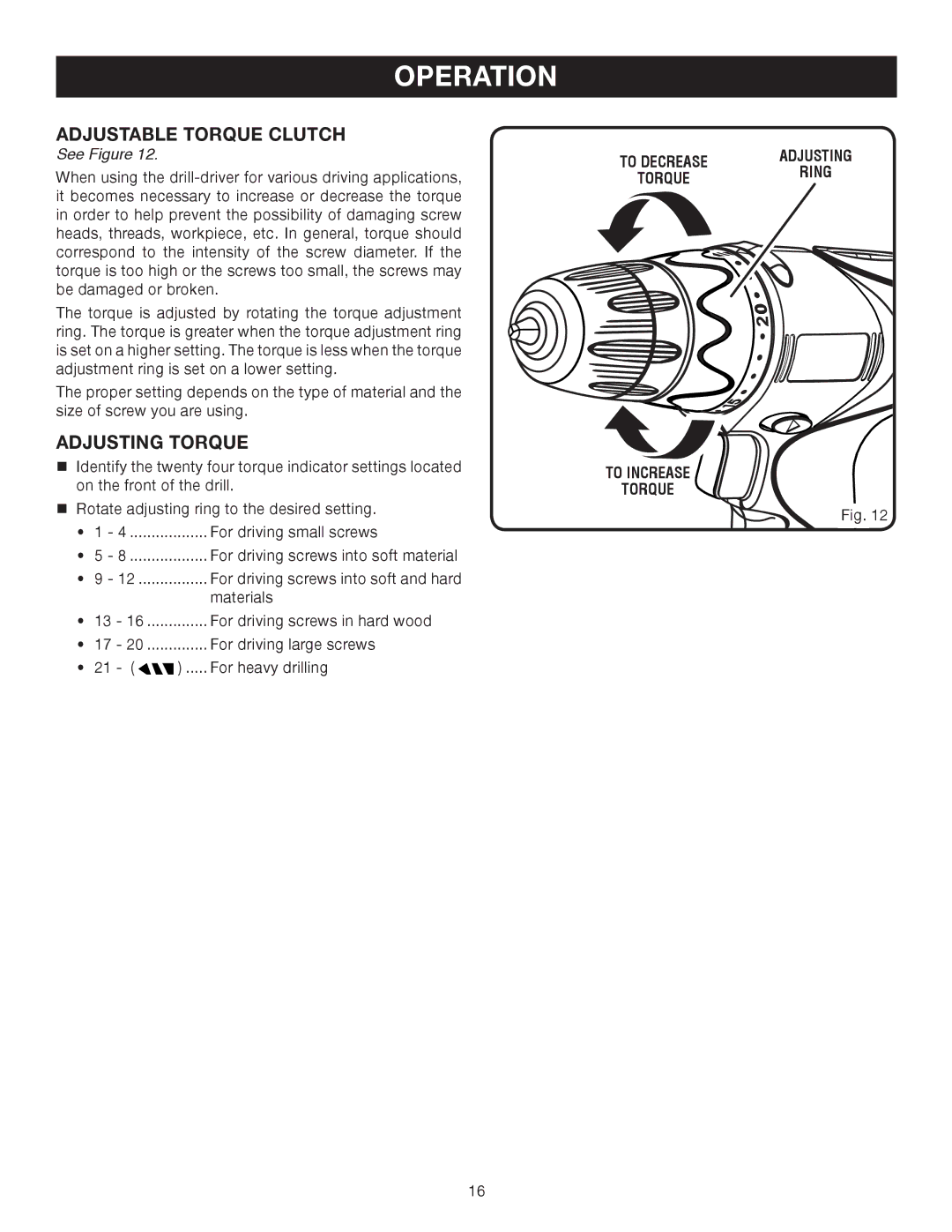

See Figure 12.

When using the

The torque is adjusted by rotating the torque adjustment ring. The torque is greater when the torque adjustment ring is set on a higher setting. The torque is less when the torque adjustment ring is set on a lower setting.

The proper setting depends on the type of material and the size of screw you are using.

ADJUSTING TORQUE

nIdentify the twenty four torque indicator settings located on the front of the drill.

nRotate adjusting ring to the desired setting.

• | 1 | - 4 | For driving small screws | ||

• | 5 | - 8 | For driving screws into soft material | ||

• | 9 | - 12 | For driving screws into soft and hard | ||

|

|

|

|

| materials |

• | 13 | - 16 | For driving screws in hard wood | ||

• | 17 | - 20 | For driving large screws | ||

• | 21 | - ( | ) | For heavy drilling | |

TO DECREASE | ADJUSTING | |

RING | ||

TORQUE | ||

|

TO INCREASE

TORQUE

Fig. 12

16