OPERATION

CAUTION:

To prevent damage to the spindle or spindle lock, always allow motor to come to a complete stop before engaging the spindle lock.

USING THE MANDRELS

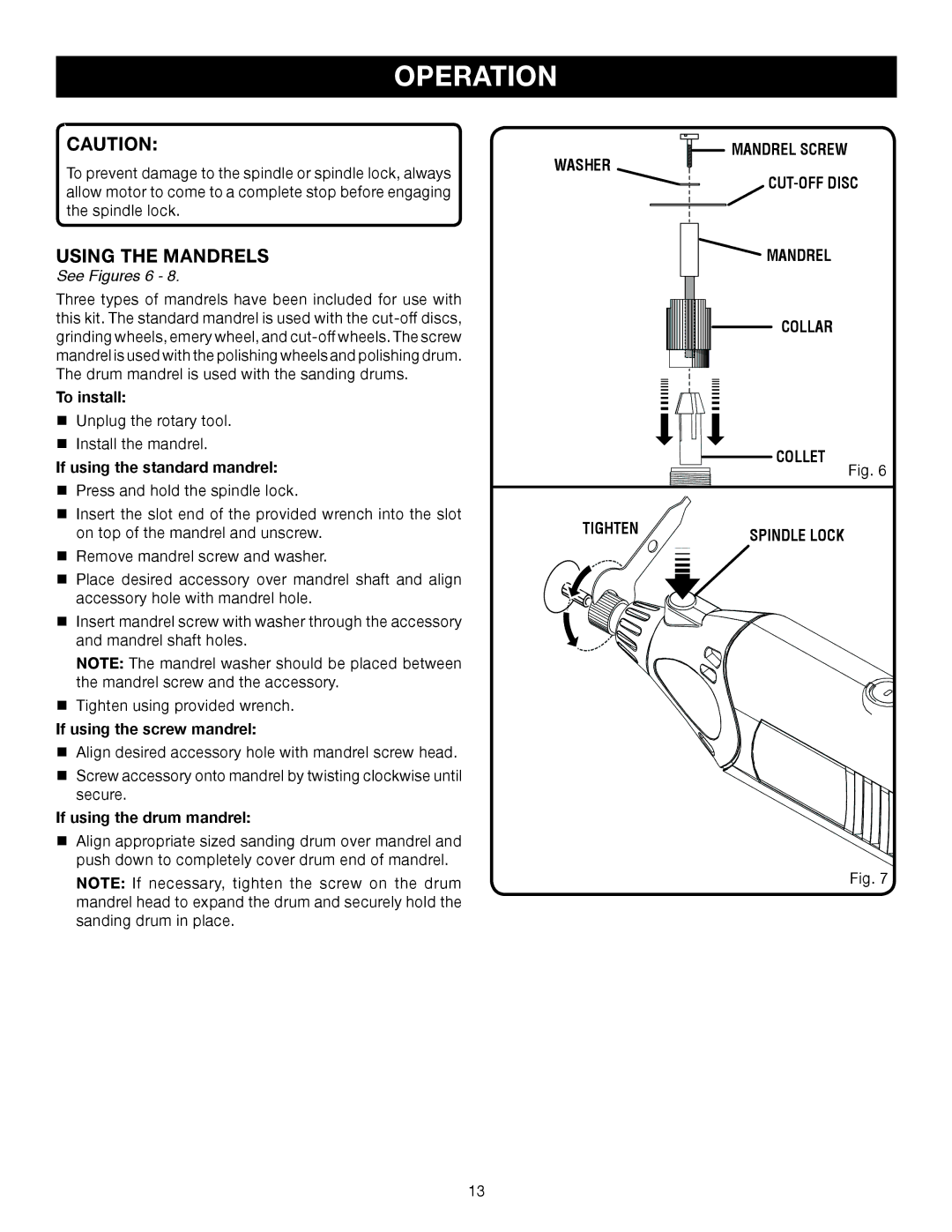

See Figures 6 - 8.

Three types of mandrels have been included for use with this kit. The standard mandrel is used with the

To install:

Unplug the rotary tool.

Install the mandrel.

If using the standard mandrel:

Press and hold the spindle lock.

Insert the slot end of the provided wrench into the slot on top of the mandrel and unscrew.

Remove mandrel screw and washer.

Place desired accessory over mandrel shaft and align accessory hole with mandrel hole.

Insert mandrel screw with washer through the accessory and mandrel shaft holes.

NOTE: The mandrel washer should be placed between the mandrel screw and the accessory.

Tighten using provided wrench.

If using the screw mandrel:

Align desired accessory hole with mandrel screw head.

Screw accessory onto mandrel by twisting clockwise until secure.

If using the drum mandrel:

Align appropriate sized sanding drum over mandrel and push down to completely cover drum end of mandrel.

NOTE: If necessary, tighten the screw on the drum mandrel head to expand the drum and securely hold the sanding drum in place.

![]()

![]() MANDREL SCREW WASHER

MANDREL SCREW WASHER ![]()

![]() MANDREL

MANDREL

COLLAR

COLLET

Fig. 6

TIGHTEN | SPINDLE LOCK |

|

Fig. 7

13