OPERATION

BALANCING ACCESSORIES

For precision work, it is important that all accessories be properly balanced. To balance an accessory, slightly loosen the collet nut and give the accessory or collet a 1/4 in. turn. You should be able to tell by the sound and feel if the accessory is running in balance. Continue adjusting in this fashion until the best balance is achieved. Replace accessories if they become damaged or unbalanced.

SELECTING THE RIGHT SPEED

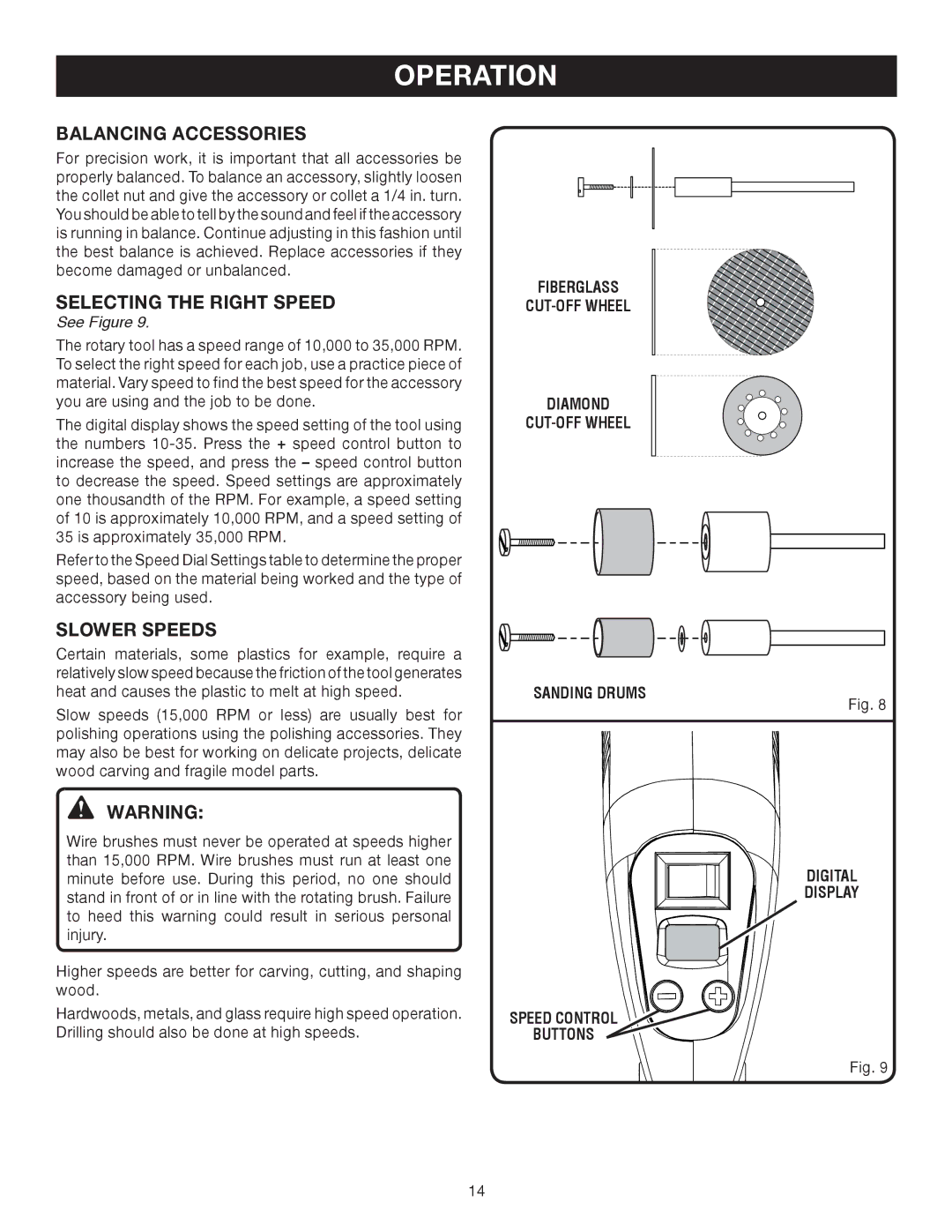

See Figure 9.

The rotary tool has a speed range of 10,000 to 35,000 RPM. To select the right speed for each job, use a practice piece of material. Vary speed to find the best speed for the accessory you are using and the job to be done.

The digital display shows the speed setting of the tool using the numbers

Refer to the Speed Dial Settings table to determine the proper speed, based on the material being worked and the type of accessory being used.

SLOWER SPEEDS

Certain materials, some plastics for example, require a relatively slow speed because the friction of the tool generates heat and causes the plastic to melt at high speed.

Slow speeds (15,000 RPM or less) are usually best for polishing operations using the polishing accessories. They may also be best for working on delicate projects, delicate wood carving and fragile model parts.

WARNING:

Wire brushes must never be operated at speeds higher than 15,000 RPM. Wire brushes must run at least one minute before use. During this period, no one should stand in front of or in line with the rotating brush. Failure to heed this warning could result in serious personal injury.

Higher speeds are better for carving, cutting, and shaping wood.

Hardwoods, metals, and glass require high speed operation. Drilling should also be done at high speeds.

FIBERGLASS

DIAMOND

SANDING DRUMS

Fig. 8

DIGITAL

DISPLAY

SPEED CONTROL

BUTTONS

Fig. 9

14