MAINTENANCE

CHAIN TENSION

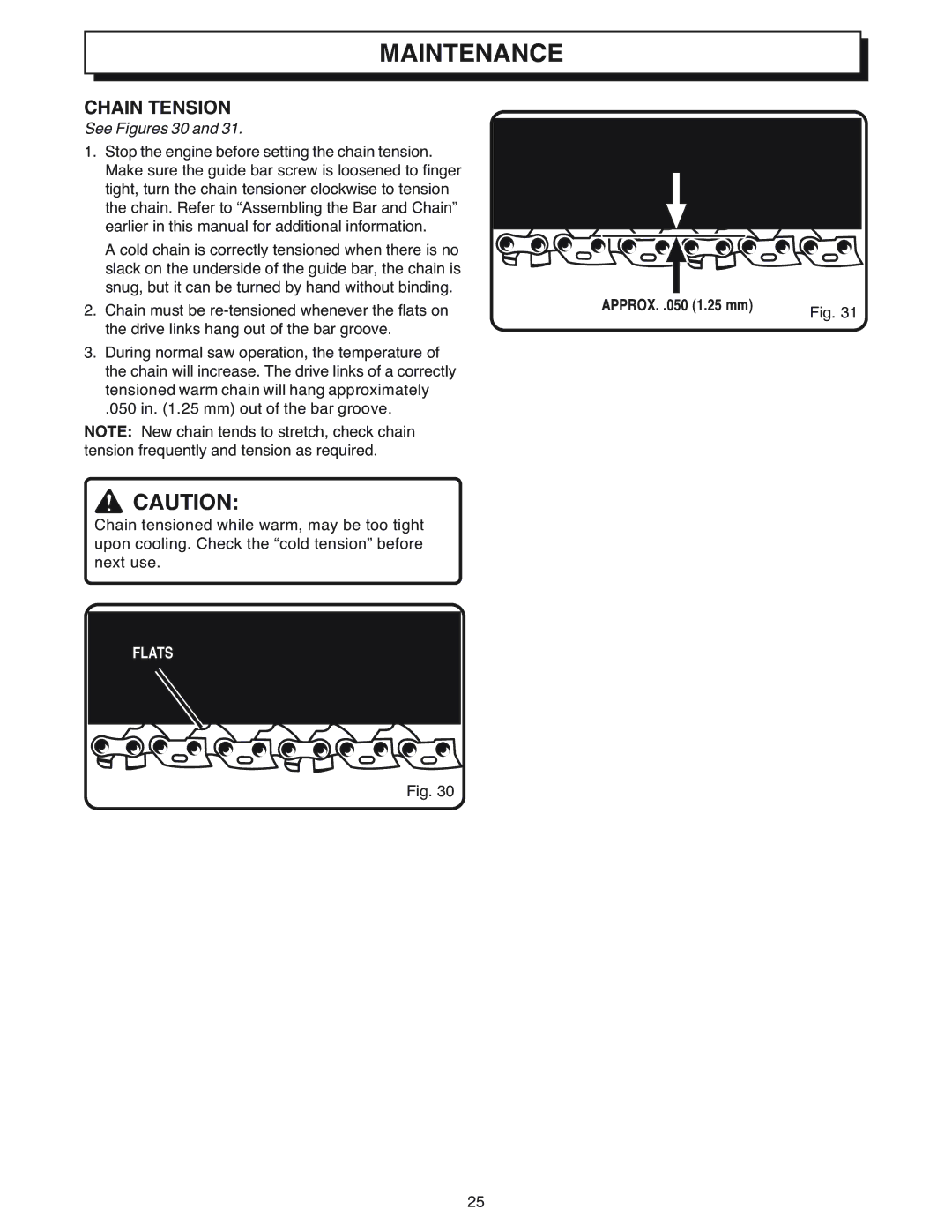

See Figures 30 and 31.

1.Stop the engine before setting the chain tension. Make sure the guide bar screw is loosened to finger tight, turn the chain tensioner clockwise to tension the chain. Refer to “Assembling the Bar and Chain” earlier in this manual for additional information.

A cold chain is correctly tensioned when there is no slack on the underside of the guide bar, the chain is snug, but it can be turned by hand without binding.

2.Chain must be

3.During normal saw operation, the temperature of the chain will increase. The drive links of a correctly tensioned warm chain will hang approximately

.050 in. (1.25 mm) out of the bar groove.

NOTE: New chain tends to stretch, check chain tension frequently and tension as required.

![]() CAUTION:

CAUTION:

Chain tensioned while warm, may be too tight upon cooling. Check the “cold tension” before next use.

FLATS

Fig. 30

25

APPROX. .050 (1.25 mm) | Fig. 31 |

|