ECOi - 2 and 3 pipe electric VRF systems

Since its formation in 1958, SANYO Air Conditioners has been at the forefront of innovation with its

Benefits

Ease of installation

R410A has a higher operating pressure with a lower pressure loss than previous refrigerants. This enables smaller pipe sizes to be used and allows reduced refrigerant charges.

Simple to design

SANYO recognise that designing, selecting and preparing a professional VRF quotation can be a time consuming and costly process, especially as it is often also a speculative exercise. So we have designed proprietary software which is quick and easy to use and produces a full schematic layout of pipework and controls, as well as a full materials list and performance data.

Easy to position

The compact design of the ECOi outdoor units means that they fit into a standard lift and are easy to handle and position when on site. The small footprint and modular appearance of the units ensure a cohesive appearance to an installation.

Off-coil temperature control

SANYO ducted units offer the unique advantage of being able to offer

Easy to control

A wide variety of control options are available to ensure that the ECOi system provides the user with the degree of control that they desire, from simple room controllers through to state of the art BMS controls.

Simple to commission

Simple

Accurate capacity control

To ensure that the compressor capacity is matched to building load as accurately and efficiently as possible, SANYO has designed its range of 2 and 3 way ECOi systems to operate with DC inverter and high‑efficiency fixed speed compressors. The system selects the most efficient compressor to operate by dynamically monitoring the building load and choosing the best compressor combination to run.

Easy to maintain

Each system allows the use of prognostic and diagnostic controls routines, from refrigerant charge control through to complex fault code diagnostics, all designed to reduce the speed of maintenance calls and unit down time.

Lower running and life cycle costs

SANYO ECOi VRF systems are amongst the most efficient VRF systems on the market, offering COPs in excess of 4.0 at full load conditions. The system is also designed to make sure that we reduce the running cost of each system by using our unique road map control routine to ensure that the most efficient combination of compressors are running at any one time. Improved defrost sequencing also reduces running cost by defrosting each outdoor coil in turn when conditions allow.

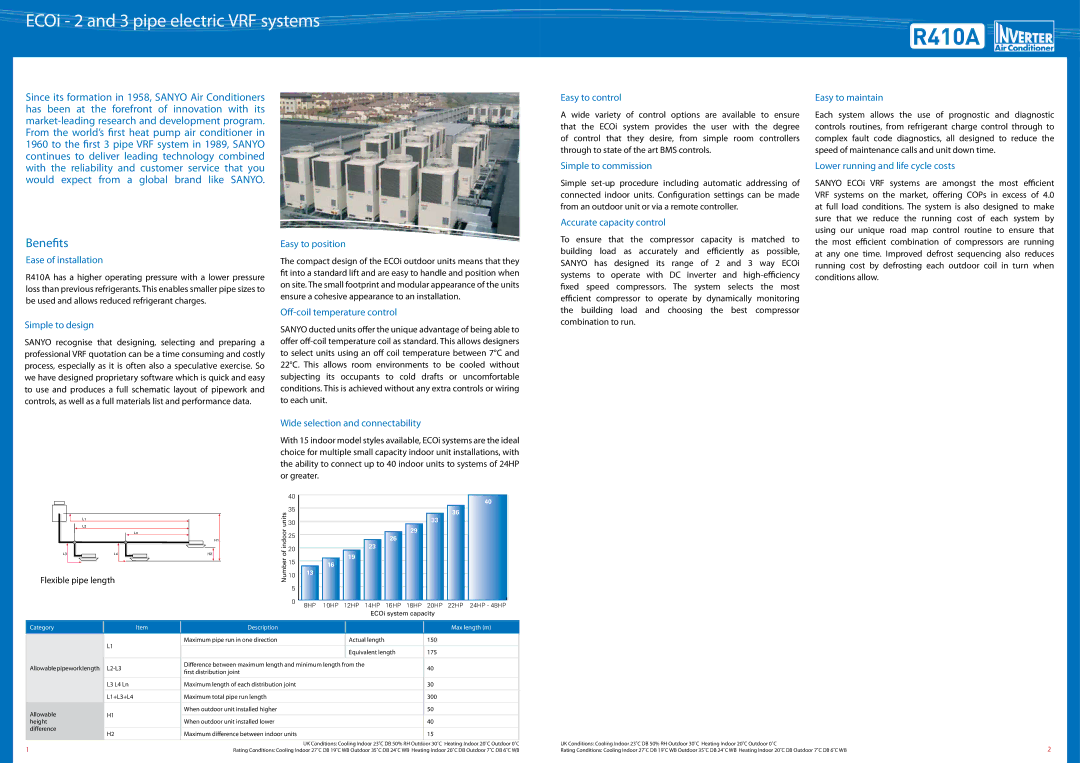

Wide selection and connectability

With 15 indoor model styles available, ECOi systems are the ideal choice for multiple small capacity indoor unit installations, with the ability to connect up to 40 indoor units to systems of 24HP or greater.

L1 |

L2 |

Ln |

H1 |

L3 | L4 | H2 |

Flexible pipe length

Number of indoor units

40

35

30

25

20

15

10

5

0

40

36

33

29

26

23

19

16

13

8HP 10HP 12HP 14HP 16HP 18HP 20HP 22HP 24HP - 48HP ECOi system capacity

Category | Item | Description |

| Max length (m) |

| L1 | Maximum pipe run in one direction | Actual length | 150 |

|

| Equivalent length | 175 | |

|

|

| ||

Allowablepipeworklength | Difference between maximum length and minimum length from the | 40 | ||

first distribution joint |

| |||

|

|

|

| |

| L3 L4 Ln | Maximum length of each distribution joint |

| 30 |

| L1+L3+L4 | Maximum total pipe run length |

| 300 |

Allowable | H1 | When outdoor unit installed higher |

| 50 |

|

|

| ||

height |

| When outdoor unit installed lower |

| 40 |

difference | H2 | Maximum difference between indoor units |

| 15 |

|

| |||

1 |

|

| UK Conditions: Cooling Indoor 23˚C DB 50% RH Outdoor 30˚C Heating Indoor 20˚C Outdoor 0˚C | |

| Rating Conditions: Cooling Indoor 27˚C DB 19˚C WB Outdoor 35˚C DB 24˚C WB Heating Indoor 20˚C DB Outdoor 7˚C DB 6˚C WB | |||

UK Conditions: Cooling Indoor 23˚C DB 50% RH Outdoor 30˚C Heating Indoor 20˚C Outdoor 0˚C | 2 |

Rating Conditions: Cooling Indoor 27˚C DB 19˚C WB Outdoor 35˚C DB 24˚C WB Heating Indoor 20˚C DB Outdoor 7˚C DB 6˚C WB |