CT4xx Series Quick Guide | Pg 6 |

1.Remove power from the printer by placing the Power Switch in the OFF (0) position.

2.Open the Top Cover by pressing on cover

release points located on each side of the | Paper Sensor | Head Latch |

printer. |

|

|

3.Release the Print Head Assembly by pressing the Head

Latch to the rear. This allows the assembly to rotate

upwards to the left allowing easy access for media routing. Rotate the assembly until it is vertical.

4.With the Print Head Assembly in the up position, press the Paper Guide Release while adjusting the

Paper Guides until they allow a media roll to fit between them. A millimetre scale is moulded into the case to provide a guide when making the

adjustment. The Paper Guides are centre justified and interact with each other so that each moves an equal distance.

5.Make sure the Roll Holders are in the released position. If they are not, lift up on each one and they will snap to the open position.

6.Unwind approximately 12” of label material from the roll. The labels should be wound

the top of the roll. The Paper Guides will automatically position the Roll Holders to suspend the roll.

7.Route the label material through the Paper Sensor Assembly and over the Platen. Note that the Sensor is part of the left Label Roll Guide so that the Paper Sensor is always positioned in the same location relative to the left edge of the label.

8. Close and latch the Print Head Assembly. | Platten | Paper Sensor |

9.Press the LINE key so that the printer is in the OFF LINE mode and then press the FEED key. The label should advance to the next index (label gap or

CT4xx Series Quick Guide | Pg 7 |

Fanfold Media

1.Place the fanfold media behind the printer with the printing surface up.

2.Open the Top Cover by pressing on cover release points located on each side of the printer. This releases the cover latch and allows it to swing upwards on the rear mounted hinge points.

3.Carefully break out the Fanfold Access Panel from the back of the Top Cover.

4.Release the Print Head Assembly by pressing the Head Latch to the rear. This allows the assembly to rotate upwards to the left allowing easy access for ribbon routing. Rotate the assembly until it is vertical.

5.With the Print Head Assembly in the up position, press the Paper Guide Release while adjusting the Paper Guides until they allow a media to fit between them. A millimetre scale is moulded into the case to provide a guide when making the adjustment. The Paper Guides are centre justified and interact with each other so that each moves an equal distance.

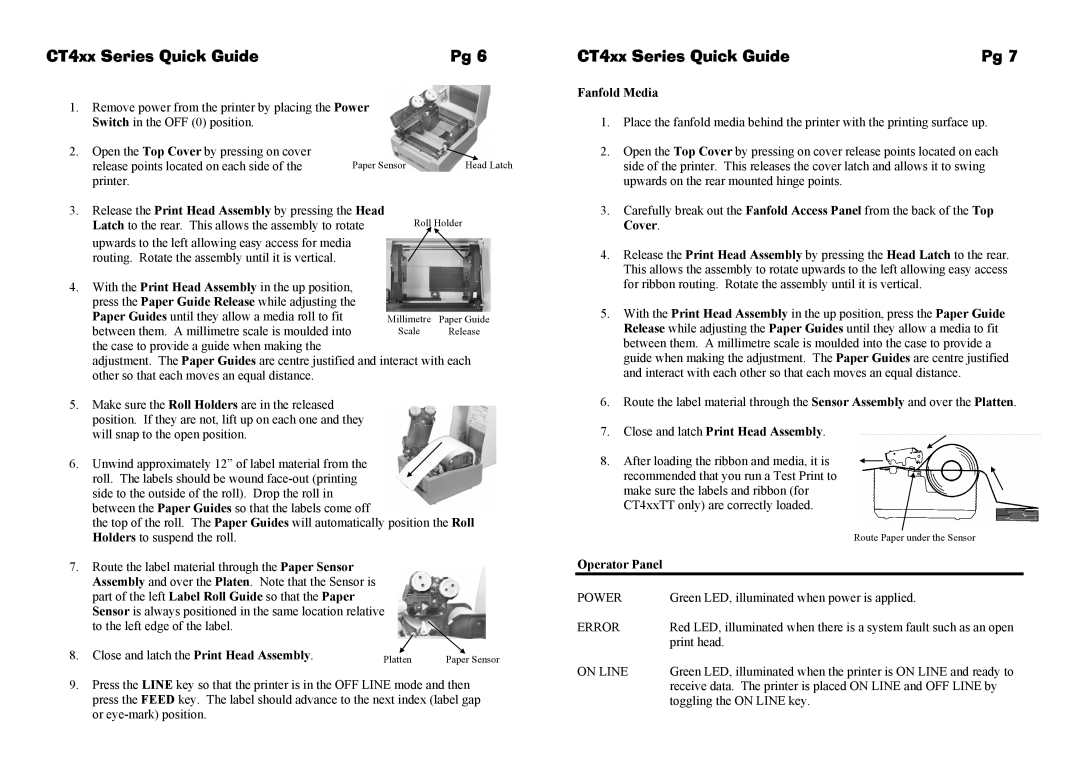

6.Route the label material through the Sensor Assembly and over the Platten.

7.Close and latch Print Head Assembly.

8.After loading the ribbon and media, it is recommended that you run a Test Print to make sure the labels and ribbon (for CT4xxTT only) are correctly loaded.

| Route Paper under the Sensor |

Operator Panel |

|

POWER | Green LED, illuminated when power is applied. |

ERROR | Red LED, illuminated when there is a system fault such as an open |

| print head. |

ON LINE | Green LED, illuminated when the printer is ON LINE and ready to |

| receive data. The printer is placed ON LINE and OFF LINE by |

| toggling the ON LINE key. |