Section 7 | R |

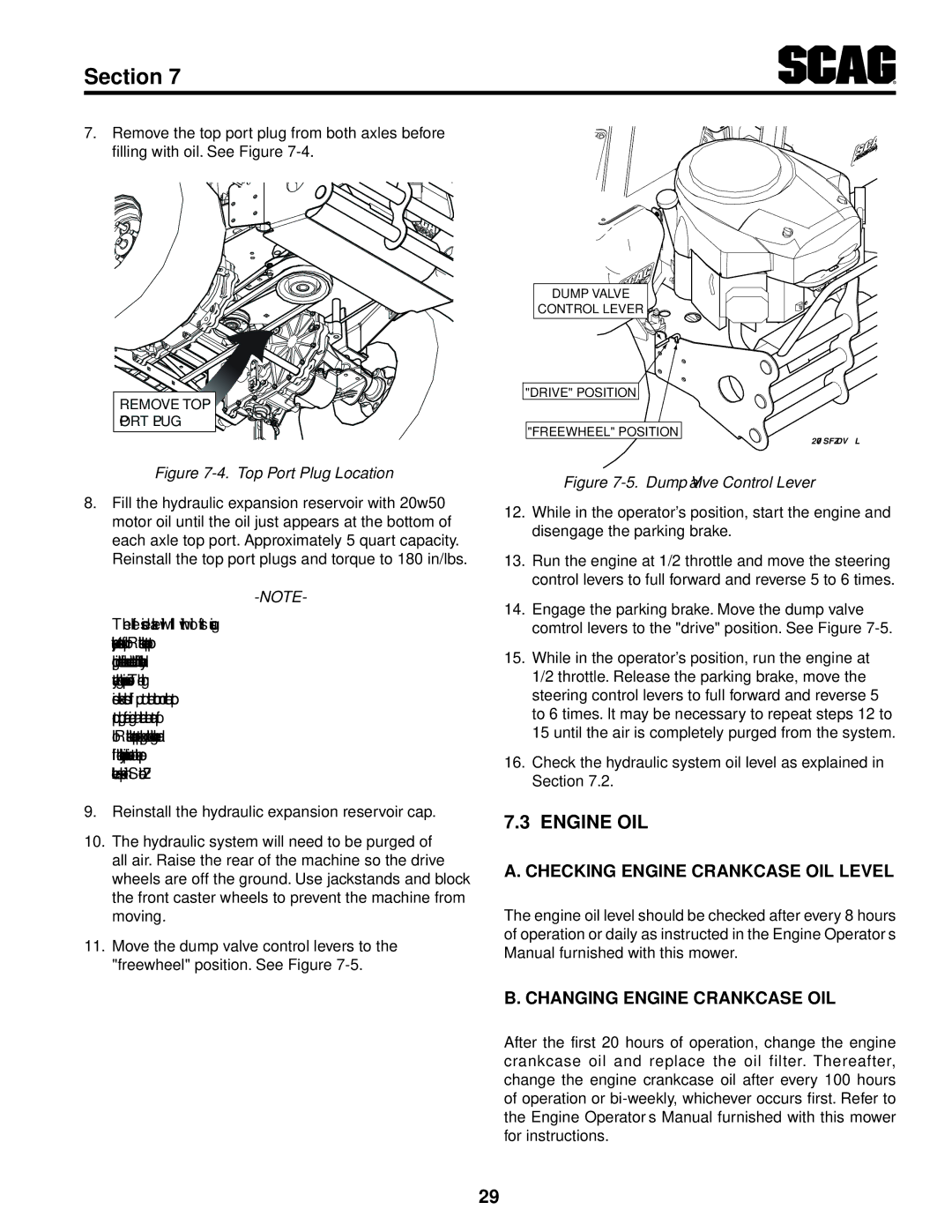

7.Remove the top port plug from both axles before filling with oil. See Figure

REMOVE TOP

PORT PLUG ![]()

![]()

![]()

![]()

![]()

![]()

Figure 7-4. Top Port Plug Location

8.Fill the hydraulic expansion reservoir with 20w50 motor oil until the oil just appears at the bottom of each axle top port. Approximately 5 quart capacity. Reinstall the top port plugs and torque to 180 in/lbs.

The left side axle will fill with oil first using approximately 4 quarts of oil. Reinstall the top port plug in the left axle and continue to fill the hydraulic system through the expansion reservoir. The right side axle should fill up to the bottom on the top port plug after adding an additional one quart of oil. Reinstall the top port plug on the right axle and fill the hydraulic expansion reservoir to the proper level as explained in Section 7.2.

9.Reinstall the hydraulic expansion reservoir cap.

10.The hydraulic system will need to be purged of all air. Raise the rear of the machine so the drive wheels are off the ground. Use jackstands and block the front caster wheels to prevent the machine from moving.

11.Move the dump valve control levers to the "freewheel" position. See Figure

DUMP VALVE

CONTROL LEVER

"DRIVE" POSITION

"FREEWHEEL" POSITION

2007 SFZ DVL

Figure 7-5. Dump Valve Control Lever

12.While in the operator's position, start the engine and disengage the parking brake.

13.Run the engine at 1/2 throttle and move the steering control levers to full forward and reverse 5 to 6 times.

14.Engage the parking brake. Move the dump valve comtrol levers to the "drive" position. See Figure

15.While in the operator's position, run the engine at 1/2 throttle. Release the parking brake, move the steering control levers to full forward and reverse 5 to 6 times. It may be necessary to repeat steps 12 to 15 until the air is completely purged from the system.

16.Check the hydraulic system oil level as explained in Section 7.2.

7.3 Engine Oil

A. Checking Engine Crankcase Oil Level

The engine oil level should be checked after every 8 hours of operation or daily as instructed in the Engine Operator’s Manual furnished with this mower.

B. Changing Engine Crankcase Oil

After the first 20 hours of operation, change the engine crankcase oil and replace the oil filter. Thereafter, change the engine crankcase oil after every 100 hours of operation or

29