Section 7 | R |

7.8 CUTTER BLADES

A. Blade Inspection

1.Remove the ignition key before servicing the blades.

2.Raise the mower deck to the highest position. Place the lanyard pin in the highest cutting height position to prevent the cutter deck from falling.

![]() WARNING

WARNING

Always wear proper hand and eye protection when working with cutter blades.

3.Check the cutter blades for straightness. If the cutter blades appear bent, they will need to be replaced.

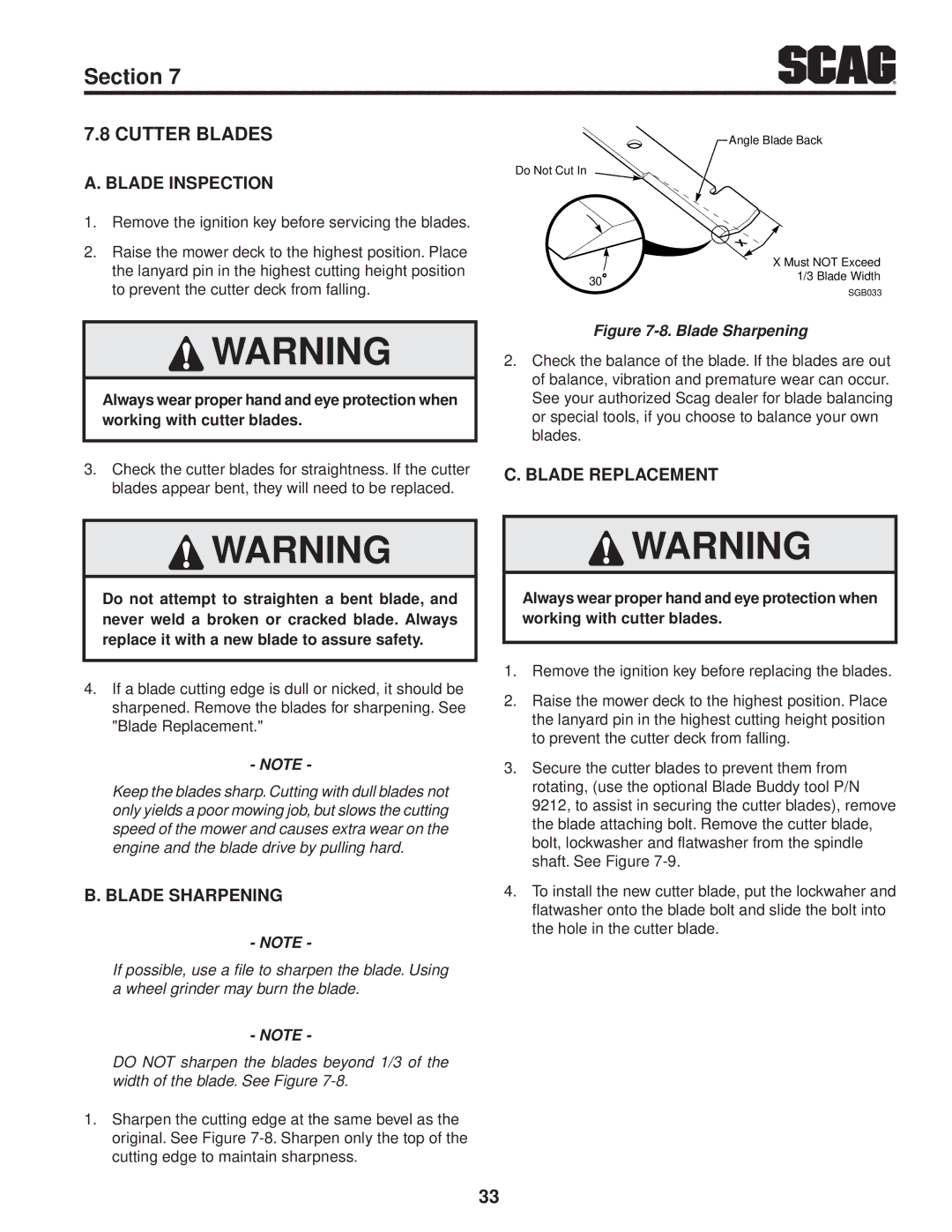

Angle Blade Back

Do Not Cut In

| X Must NOT Exceed | |

30 | 1/3 Blade Width | |

SGB033 | ||

|

Figure 7-8. Blade Sharpening

2.Check the balance of the blade. If the blades are out of balance, vibration and premature wear can occur. See your authorized Scag dealer for blade balancing or special tools, if you choose to balance your own blades.

C. Blade Replacement

![]() WARNING

WARNING

Do not attempt to straighten a bent blade, and never weld a broken or cracked blade. Always replace it with a new blade to assure safety.

4.If a blade cutting edge is dull or nicked, it should be sharpened. Remove the blades for sharpening. See "Blade Replacement."

- NOTE -

Keep the blades sharp. Cutting with dull blades not only yields a poor mowing job, but slows the cutting speed of the mower and causes extra wear on the engine and the blade drive by pulling hard.

B. Blade Sharpening

- NOTE -

If possible, use a file to sharpen the blade. Using a wheel grinder may burn the blade.

- NOTE -

![]() WARNING

WARNING

Always wear proper hand and eye protection when working with cutter blades.

1.Remove the ignition key before replacing the blades.

2.Raise the mower deck to the highest position. Place the lanyard pin in the highest cutting height position to prevent the cutter deck from falling.

3.Secure the cutter blades to prevent them from rotating, (use the optional Blade Buddy tool P/N 9212, to assist in securing the cutter blades), remove the blade attaching bolt. Remove the cutter blade, bolt, lockwasher and flatwasher from the spindle shaft. See Figure

4.To install the new cutter blade, put the lockwaher and flatwasher onto the blade bolt and slide the bolt into the hole in the cutter blade.

DO NOT sharpen the blades beyond 1/3 of the width of the blade. See Figure

1.Sharpen the cutting edge at the same bevel as the original. See Figure

33