Section 7

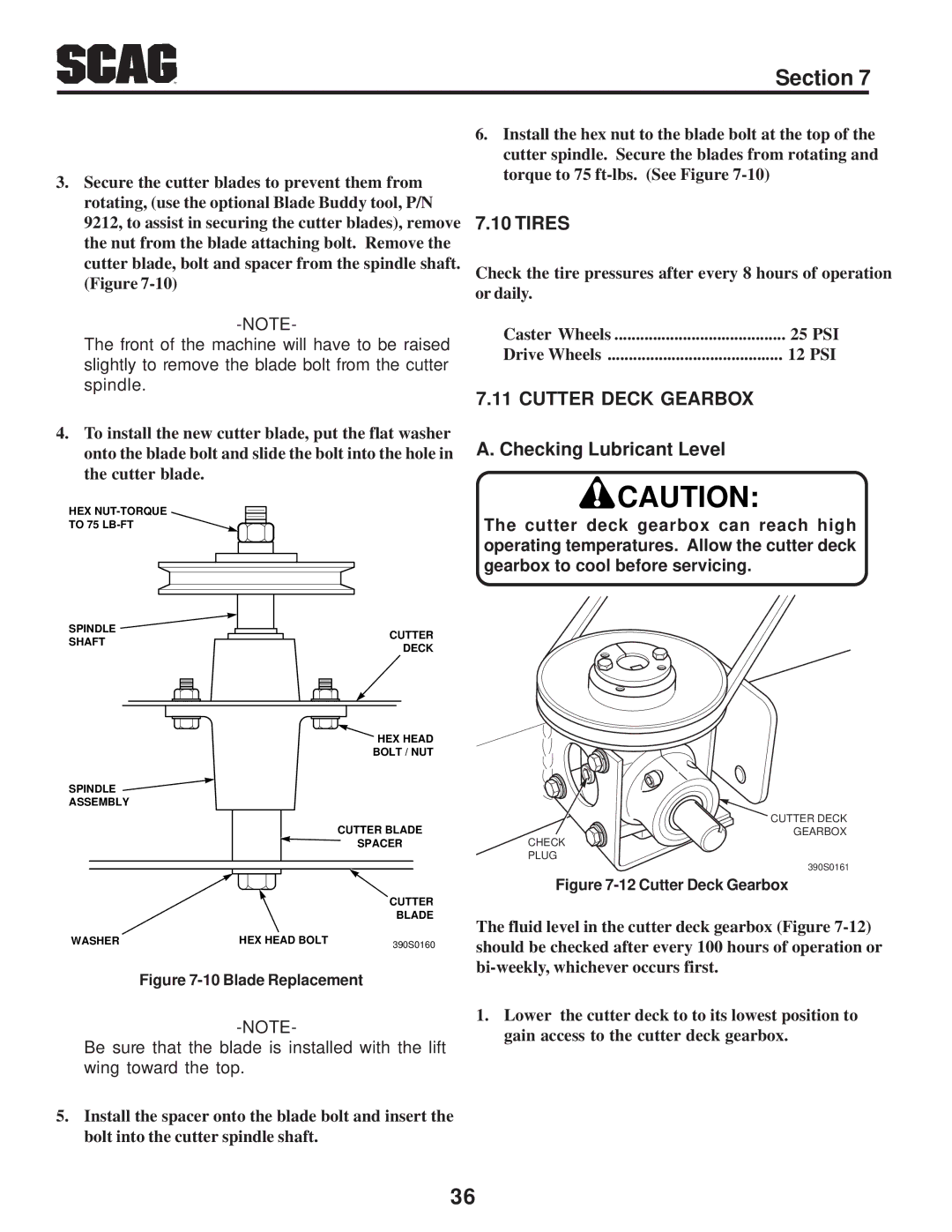

3.Secure the cutter blades to prevent them from rotating, (use the optional Blade Buddy tool, P/N 9212, to assist in securing the cutter blades), remove the nut from the blade attaching bolt. Remove the cutter blade, bolt and spacer from the spindle shaft. (Figure

The front of the machine will have to be raised slightly to remove the blade bolt from the cutter spindle.

4.To install the new cutter blade, put the flat washer onto the blade bolt and slide the bolt into the hole in the cutter blade.

HEX

TO 75

6.Install the hex nut to the blade bolt at the top of the cutter spindle. Secure the blades from rotating and torque to 75

7.10 TIRES

Check the tire pressures after every 8 hours of operation or daily.

Caster Wheels | 25 PSI |

Drive Wheels | 12 PSI |

7.11 CUTTER DECK GEARBOX

A. Checking Lubricant Level

![]() CAUTION:

CAUTION:

The cutter deck gearbox can reach high operating temperatures. Allow the cutter deck gearbox to cool before servicing.

SPINDLE ![]()

CUTTER

SHAFT

DECK

HEX HEAD

BOLT / NUT

SPINDLE

ASSEMBLY

CUTTER BLADE

SPACER

CUTTER

BLADE

WASHER | HEX HEAD BOLT | 390S0160 |

|

|

Figure 7-10 Blade Replacement

Be sure that the blade is installed with the lift wing toward the top.

5.Install the spacer onto the blade bolt and insert the bolt into the cutter spindle shaft.

CUTTER DECK

GEARBOX

CHECK

PLUG

390S0161

Figure 7-12 Cutter Deck Gearbox

The fluid level in the cutter deck gearbox (Figure

1.Lower the cutter deck to to its lowest position to gain access to the cutter deck gearbox.

36