Section 7

2.Clean and remove the check plug from the side of the gearbox (See Figure

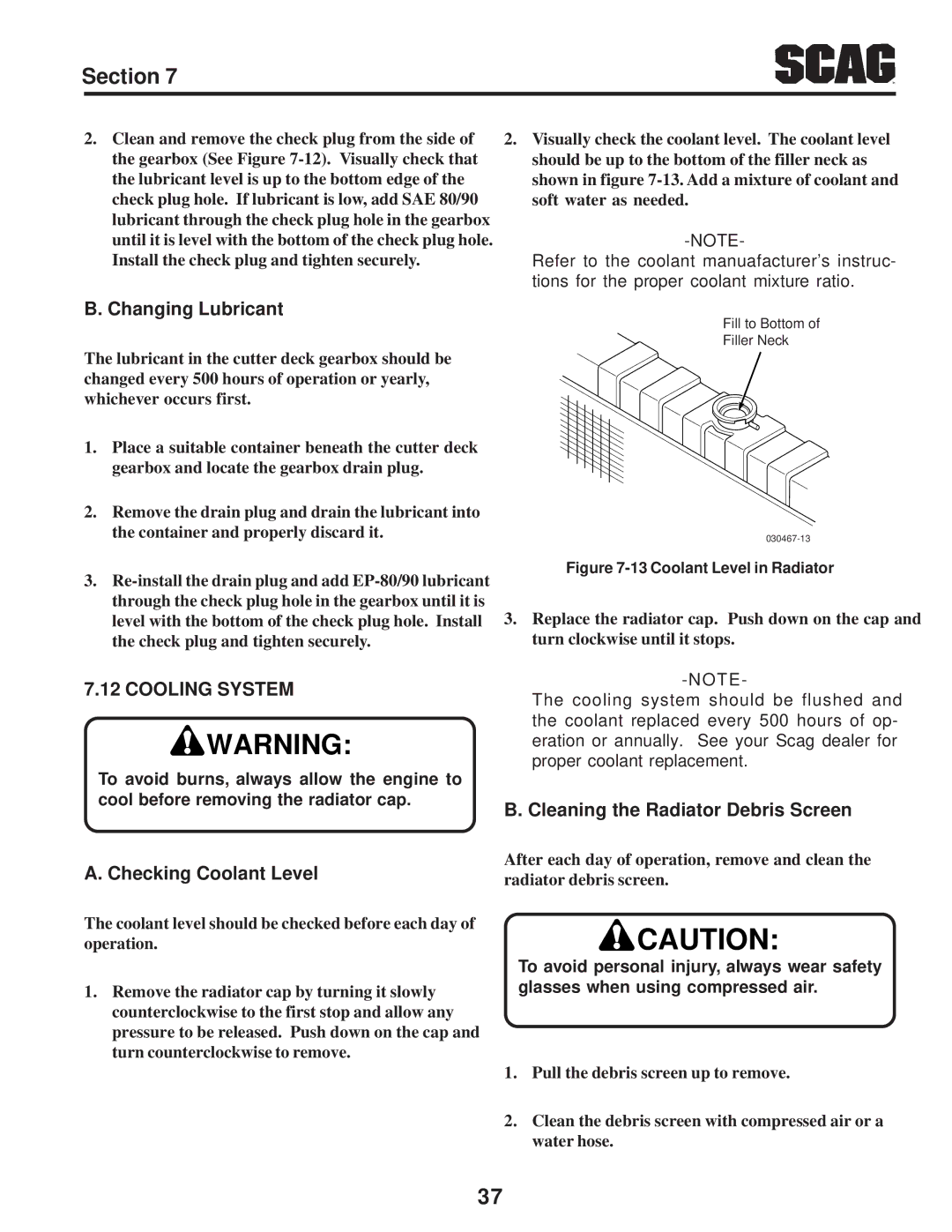

2.Visually check the coolant level. The coolant level should be up to the bottom of the filler neck as shown in figure

Refer to the coolant manuafacturer's instruc- tions for the proper coolant mixture ratio.

B. Changing Lubricant

The lubricant in the cutter deck gearbox should be changed every 500 hours of operation or yearly, whichever occurs first.

1.Place a suitable container beneath the cutter deck gearbox and locate the gearbox drain plug.

2.Remove the drain plug and drain the lubricant into the container and properly discard it.

3.

7.12 COOLING SYSTEM

![]() WARNING:

WARNING:

To avoid burns, always allow the engine to cool before removing the radiator cap.

A. Checking Coolant Level

The coolant level should be checked before each day of operation.

1.Remove the radiator cap by turning it slowly counterclockwise to the first stop and allow any pressure to be released. Push down on the cap and turn counterclockwise to remove.

Fill to Bottom of

Filler Neck

Figure 7-13 Coolant Level in Radiator

3.Replace the radiator cap. Push down on the cap and turn clockwise until it stops.

- NOT E -

The cooling system should be flushed and the coolant replaced every 500 hours of op- eration or annually. See your Scag dealer for proper coolant replacement.

B. Cleaning the Radiator Debris Screen

After each day of operation, remove and clean the radiator debris screen.

![]() CAUTION:

CAUTION:

To avoid personal injury, always wear safety glasses when using compressed air.

1.Pull the debris screen up to remove.

2.Clean the debris screen with compressed air or a water hose.

37