Contents

Models CU1526, CU2026 and CU3030

Installation and Users Manual for Self Contained Cubers

Table of Contents

CU1526, CU2026, CU3030 User Manual

Installation Product Specifications

Power supply - acceptable voltage ranges

Warranty Information

Product Description & Electrical Requirements

Water purge

Uncrate and Set Up

CU1526, CU2026, CU3030 User Manual Water

Potential for Airborne Contamination

27.5

67.6

26.62

69.9

74.6

CU1526, CU2026, CU3030 User Manual CU3030 Cabinet Layout

60.5

23.82

Page

Follow all applicable codes

Water Supply and Filters

Drain Tubing

Final Check List

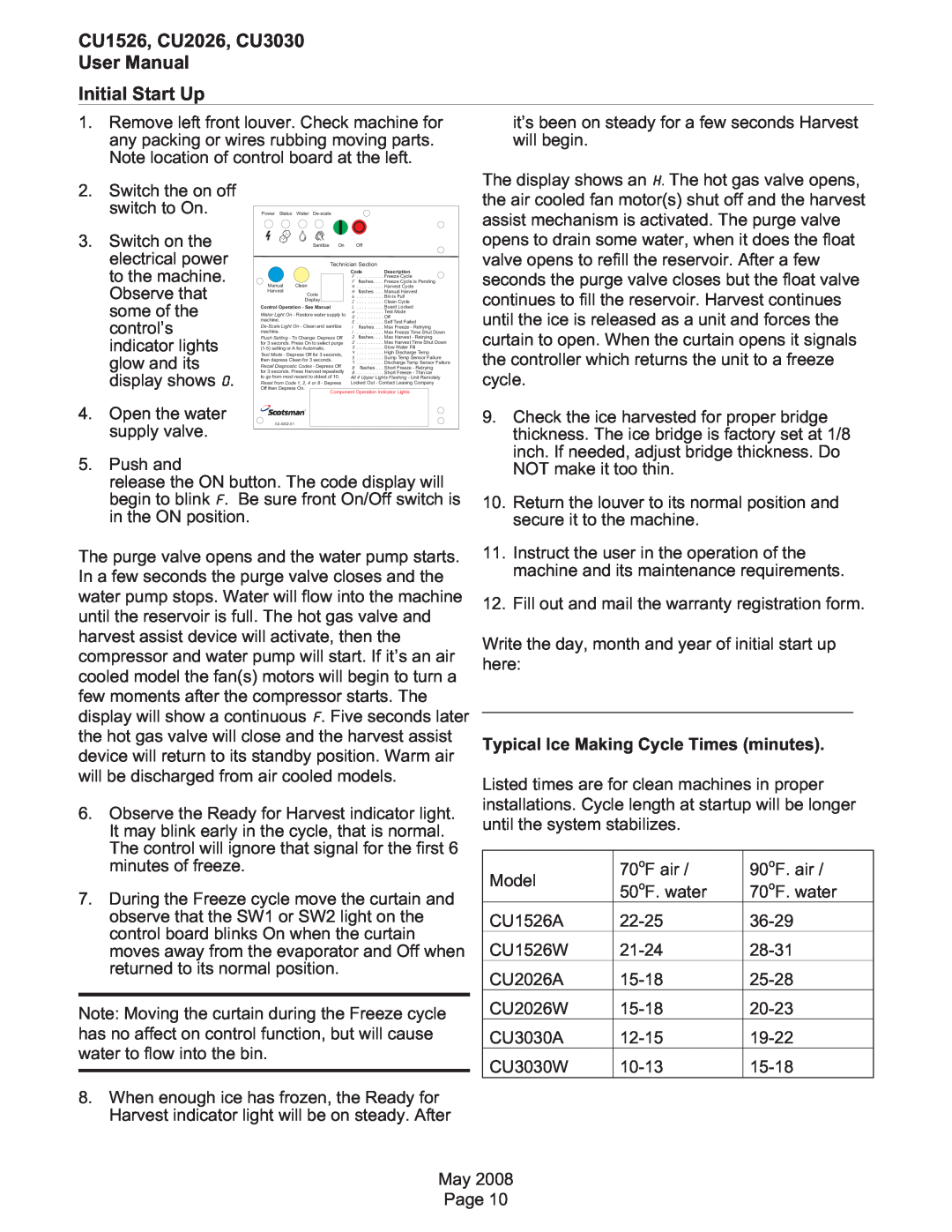

Typical Ice Making Cycle Times minutes

Too Small

Too Big

Just Right

Status

Indicator Lights

Power

CU1526, CU2026, CU3030 User Manual Use and Operation

Noise

Heat

Ice machine scale remover contains acids. Acids can cause burns

Cleaning, Sanitation and Maintenance

Water filters

Air cooled condenser filter

Air cooled condenser

Exterior Panels

To Shut the Machine Off

What to do before calling for service

To Manually Reset the machine

Check the following

17-3234-01

SCOTSMAN ICE SYSTEMS 775 Corporate Woods Parkway, Vernon Hills, IL