2.8.6.4Nonoperating random vibration

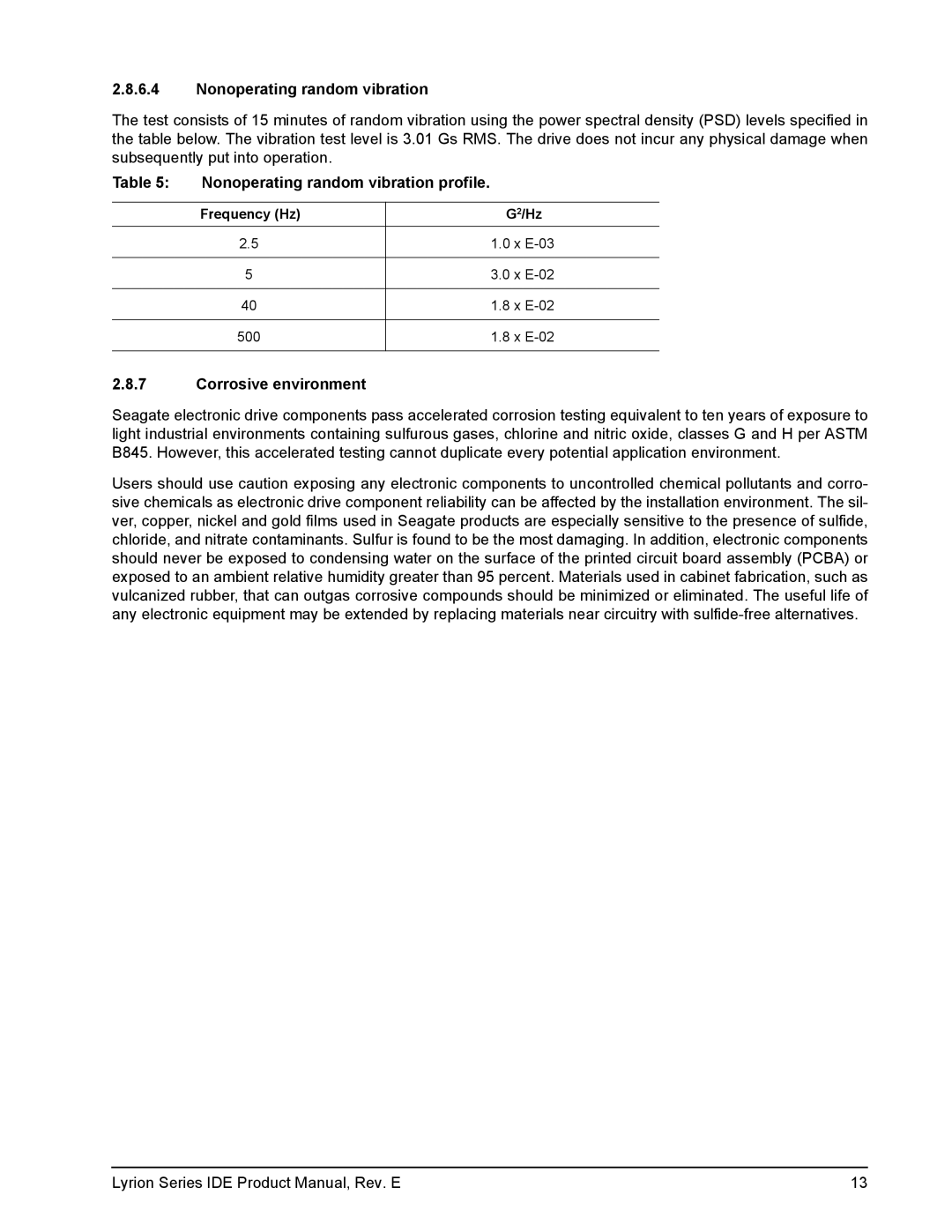

The test consists of 15 minutes of random vibration using the power spectral density (PSD) levels specified in the table below. The vibration test level is 3.01 Gs RMS. The drive does not incur any physical damage when subsequently put into operation.

Table 5: Nonoperating random vibration profile.

Frequency (Hz) | G2/Hz |

|

|

2.5 | 1.0 x |

|

|

5 | 3.0 x |

|

|

40 | 1.8 x |

|

|

500 | 1.8 x |

|

|

2.8.7Corrosive environment

Seagate electronic drive components pass accelerated corrosion testing equivalent to ten years of exposure to light industrial environments containing sulfurous gases, chlorine and nitric oxide, classes G and H per ASTM B845. However, this accelerated testing cannot duplicate every potential application environment.

Users should use caution exposing any electronic components to uncontrolled chemical pollutants and corro- sive chemicals as electronic drive component reliability can be affected by the installation environment. The sil- ver, copper, nickel and gold films used in Seagate products are especially sensitive to the presence of sulfide, chloride, and nitrate contaminants. Sulfur is found to be the most damaging. In addition, electronic components should never be exposed to condensing water on the surface of the printed circuit board assembly (PCBA) or exposed to an ambient relative humidity greater than 95 percent. Materials used in cabinet fabrication, such as vulcanized rubber, that can outgas corrosive compounds should be minimized or eliminated. The useful life of any electronic equipment may be extended by replacing materials near circuitry with

Lyrion Series IDE Product Manual, Rev. E | 13 |