RESAWING

Resowing is the cutting of thick boards into thinner ones_ It is a ripping operatiano See Figure 29. Smalt

When cutting boards thicker than 4"° a fence should be used

which extends 3½" above the table topr When cutting boards thicker than 5", cut both sides and finish the cut wlth a hand saw_

BEVEL AND MITER CUTS

Bevel cuts can be made from either a

can be made only from a

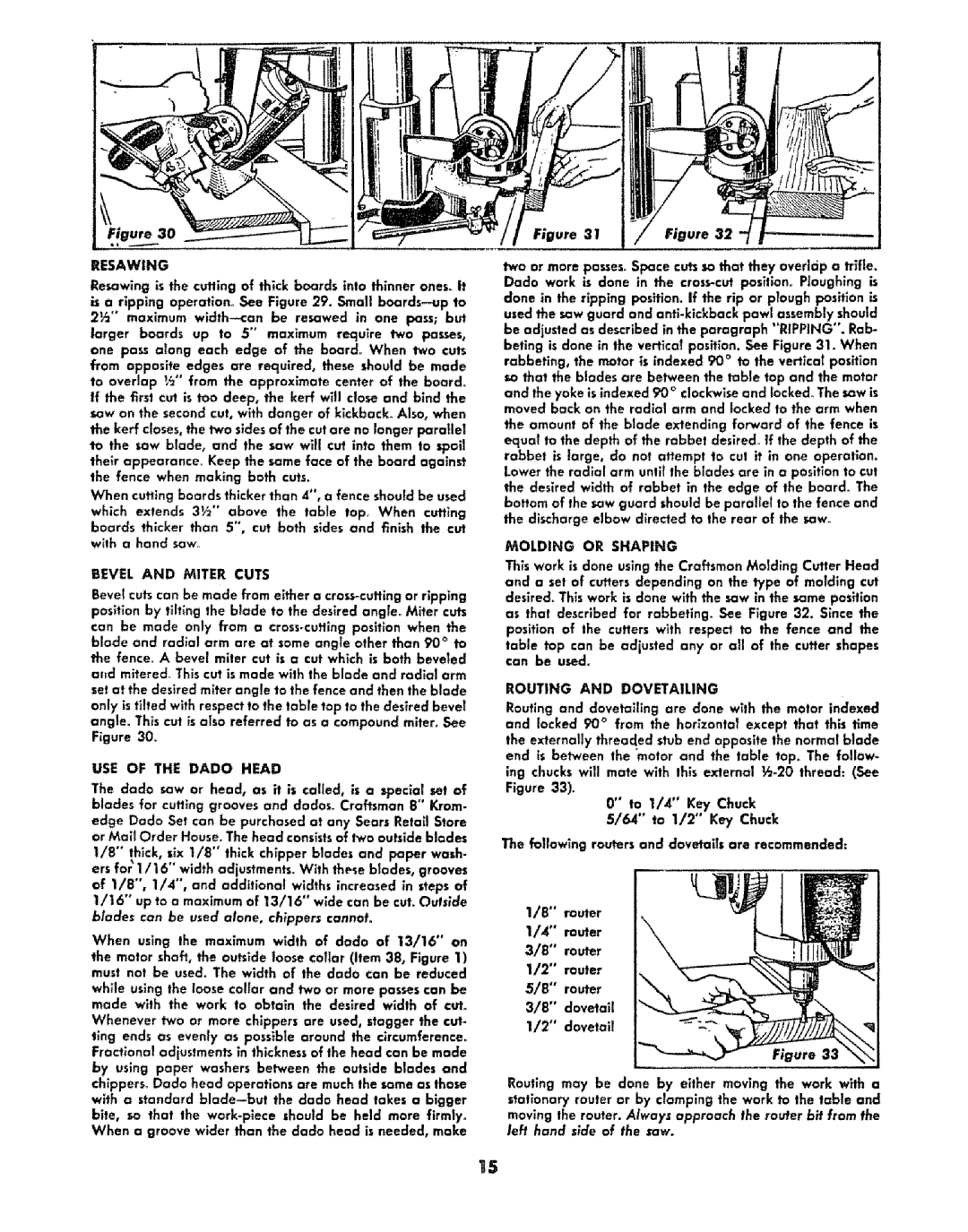

angle. This cut is also referred to as a compound miter, See

Figure 30_

USE OF THE DADO HEAD

The dado saw or head, as it is called, is a special set of blades for cutting grooves and dados_ Craftsman 8" Krom.

edge Dada Set can be purchased at any Sears Retail Store or Mall Order House. The head consistsof two autside blades

I/8" thick, six 1/8" thick chipper blades and Paper wash- ers for'1/t6" width adjustments. With these blades, grooves of 1/8", 1/4", and additional widths increased in steps of 1/t6" up to a maximum of 13/16" wide can be cut. Outside blades con be used alone, chippers cannot°

When using the moxlmum width of dado of 13/16" on

the motor shaft, the outside Ioo_e collar (Item 38, Figure 1) must not be used. The width of the dado can be reduced

while using the loose collar and two or more passes can be made with the work to obtain the desired width of cut°

Whenever two or more chippers are used, stagger the cut- ting ends as evenly as possible around the clrcumference_

Fractlanat adjustments in thickness of the head can be made by using paper washers between the outside blades and chippers° Dado head operations are much the same as those with a standard

Figure 31 | Figure 32 |

two or mare passes_Space cuts so that they oveddp a trifle. Dado work is done in the

MOLDING OR SHAPING

Th_swork is done using the Craftsman Molding Cutter Head and a set of cutters depending on the type of molding cut desired. This work is done with the saw in the some position as that described for rabbetlng_ See Figure 32. Since the position of the cutters with respect to the fence and the

table top can be adjusted any or all of the cutter shapes can be used.

ROUTING AND DOVETAILING

Routing and dovetailing are done with the motor indexed and locked 90 ° from the horizanta! except that this time the externally threaded stub end opposite the normal blade end is between the "motor and the table top. The foffow- ing chucks will mate with this external

Figure 33)°

0 '°to 1/,_" Key Chuck 5/64" to I/2" Key Chuck

The followlng routers and dovetails are recommended:

1/8" muter

1/4'"router 3/8" router

1/2" router 5/8" router 3/8" dovetail 1/2 °° dovetoff

Figure 33

Routing may be done by either moving the work wffh a stationary router or by clamping the work to the table and

moving the router. Always approach the router bit from the left hand side af the saw.

15