OPERATION

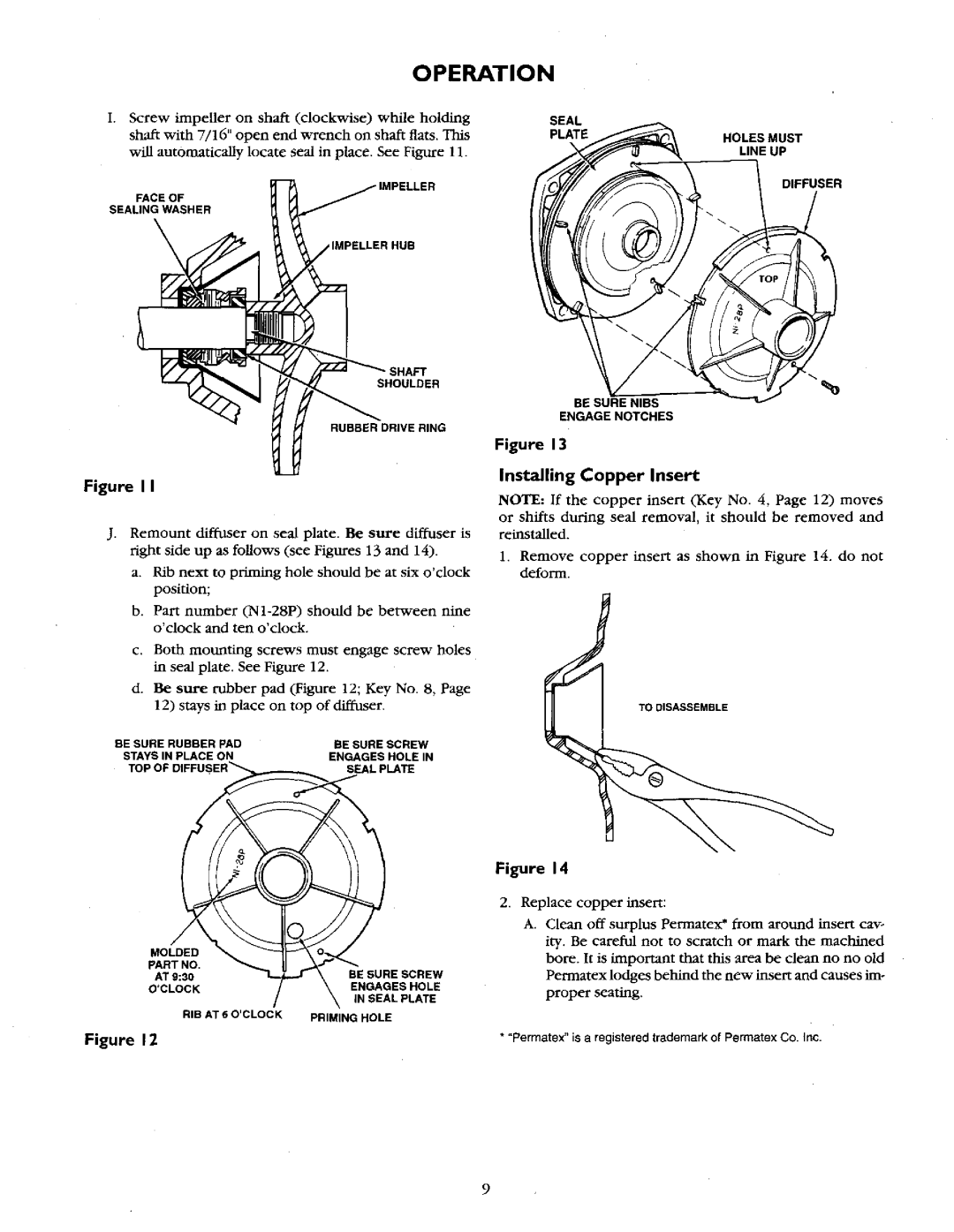

I. Screw impeller on shaft (clockwise) while holding shaft wzth 7/16" open end wrench on shaft flats. This

v_fll automatically locate seal in place. See Figure 11.

FACE OF

SEALING WASHER

IMPELLER HUB

SHAFT

SHOULDER

SEAL PLATE

HOLES MUST

LINE UP

DIFFUSER

%

RUBBER DRIVE RING

Figure I I

Remount diffuser on seal plate. Be sure diffuser is right side up as follows (see Figures 13 and 14).

a.Rib next to priming hole should be at six o'clock position;

b.Part number

c.Both mounting screws must engage screw holes in seal plate. See Figure 12.

d.Be sure rubber pad (Figure 12; Key No. 8, Page

12)stays in place on top of diffuser.

BE SURE | RUBBER | PAD | BESURESCREW |

STAYS | IN PLACE | ON | ENGAGES HOLE IN |

|

|

| SEALPLATE |

BE SURE NIBS

ENGAGE NOTCHES

Figure 13

Installing Copper Insert

NOTE: If the copper insert (Key No. 4, Page 12) moves

or shifts during seal removal, it should be removed and reinstalled.

1.Remove copper insert as shown in Figure 14. do not deform.

TO DISASSEMBLE

MOLDED |

|

|

PART NO. |

|

|

AT 9:30 | BE SURE | SCREW |

O'CLOCK | ENGAGES | HOLE |

| IN SEAL | PLATE |

RIB AT E O'CLOCK | PRIMING HOLE |

|

|

|

Figure 14

2.Replace copper insert:

A.Clean off surplus Permatex* from around insert cav- ity. Be careful not to scratch or mark the machined

bore. It is important that this area be clean no no old Permatex lodges behind the new insert and causes im-

proper seating.

Figure 12 | * "Permatex" is a registered trademark of Permatex Co. Inc. |