917.258524 specifications

The Sears 917.258524 is a notable addition to the landscape of outdoor power equipment, specifically in the realm of lawn maintenance. This model, known for its durability and efficiency, represents a standard of excellence in residential lawn care machinery.One of the main features of the Sears 917.258524 is its powerful engine. Equipped with a reliable gasoline engine, this model offers robust performance that allows users to tackle a wide variety of lawn conditions, from smooth suburban lawns to rugged terrains. Its engine is designed to provide high torque, enabling the mower to cut through thick grass and even overgrown areas with ease.

The cutting deck of the 917.258524 is another standout feature. With a generous width, typically around 21 inches, it allows for efficient mowing over larger areas in a shorter amount of time. The adjustable cutting height is a practical attribute, offering multiple settings for different grass types and seasonal conditions. This versatility ensures that users can maintain their lawns at the desired height across various weather patterns.

In terms of technology, the Sears 917.258524 incorporates a self-propelling mechanism, making it easier for users to maneuver across slopes and uneven ground without excessive physical effort. This feature is particularly beneficial for those who may find traditional push mowers cumbersome.

The mower also boasts a user-friendly interface, often equipped with easy-to-reach controls for starting and stopping the engine, as well as for adjusting the speed and cutting height. This intuitive design enhances the overall user experience, making it accessible even for beginners.

Durability is a key characteristic of the Sears 917.258524. Constructed with high-quality materials, both the chassis and the cutting deck are designed to withstand the elements and resist corrosion. This ensures that the mower maintains its performance and appearance over time, providing long-lasting value to consumers.

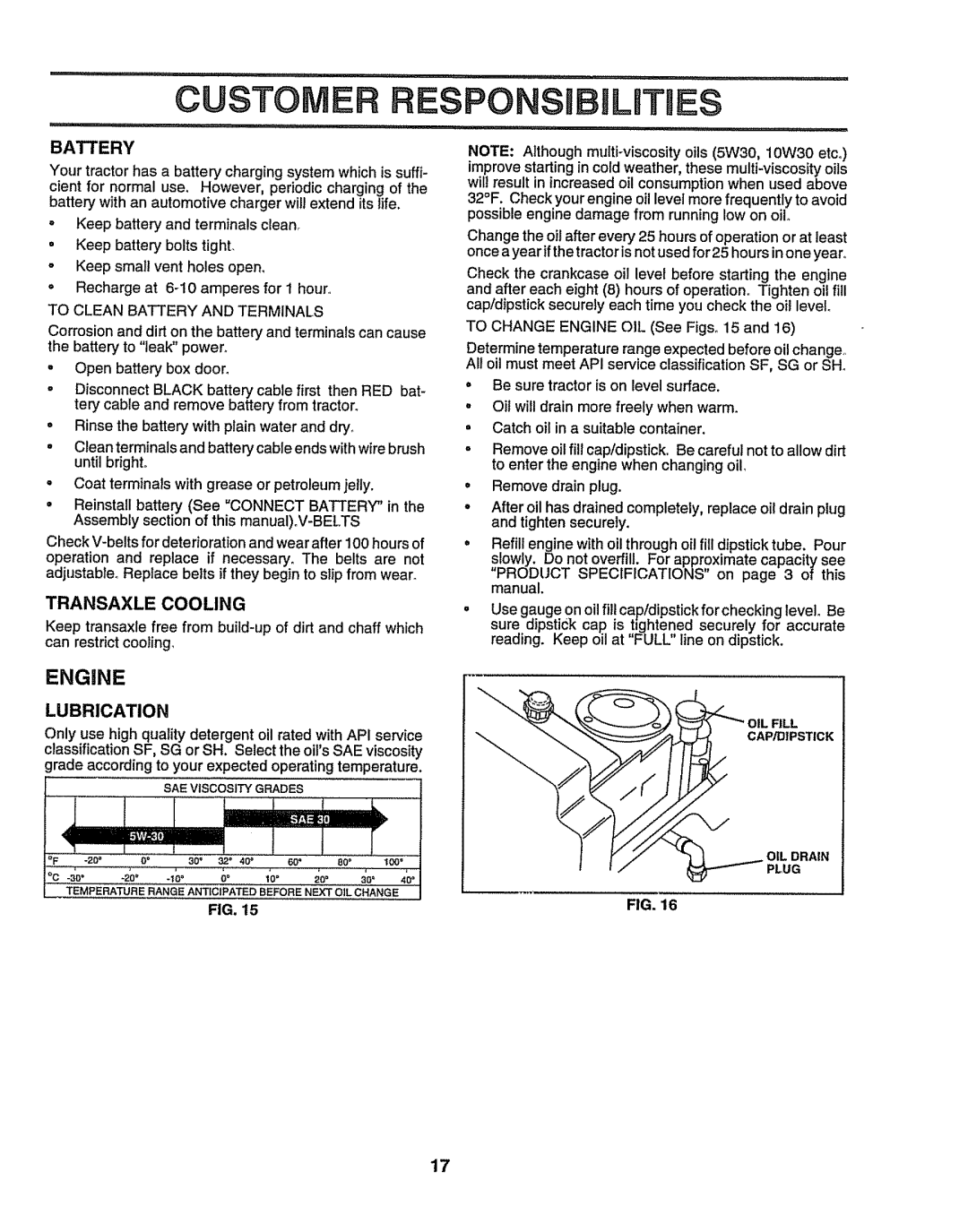

Finally, the Sears 917.258524 takes maintenance into consideration. With features that simplify cleaning and oil changes, users can easily care for their mower, ensuring it remains in peak condition year after year. Overall, the Sears 917.258524 stands out as a reliable, efficient, and user-friendly option for homeowners seeking to keep their lawns well-manicured.