OPERATION

Do not operate this Equipment with hydraulic oil or fuel leaking. Oil and fuel are explosive and their presence could present a hazard. Do not check for leaks with your hand!

Before operation, a complete inspection and service is required to ensure the loader is in a good and safe

working condition. Damaged and/or broken parts should be repaired and/or replaced immediately. To ensure the loader is ready for operation, conduct the following.

The operator’s manual and safety signs affixed on the unit contain important instructions on the safe and proper use of the equipment. Maintain these important safety features on the implement in good condition to ensure the information is available to the operator at all times.

•Ensure the manual canister is secured to the equipment with the operator’s manual inside.

•Ensure all safety signs are in place and legible. Replace missing, damaged, and illegible decals.

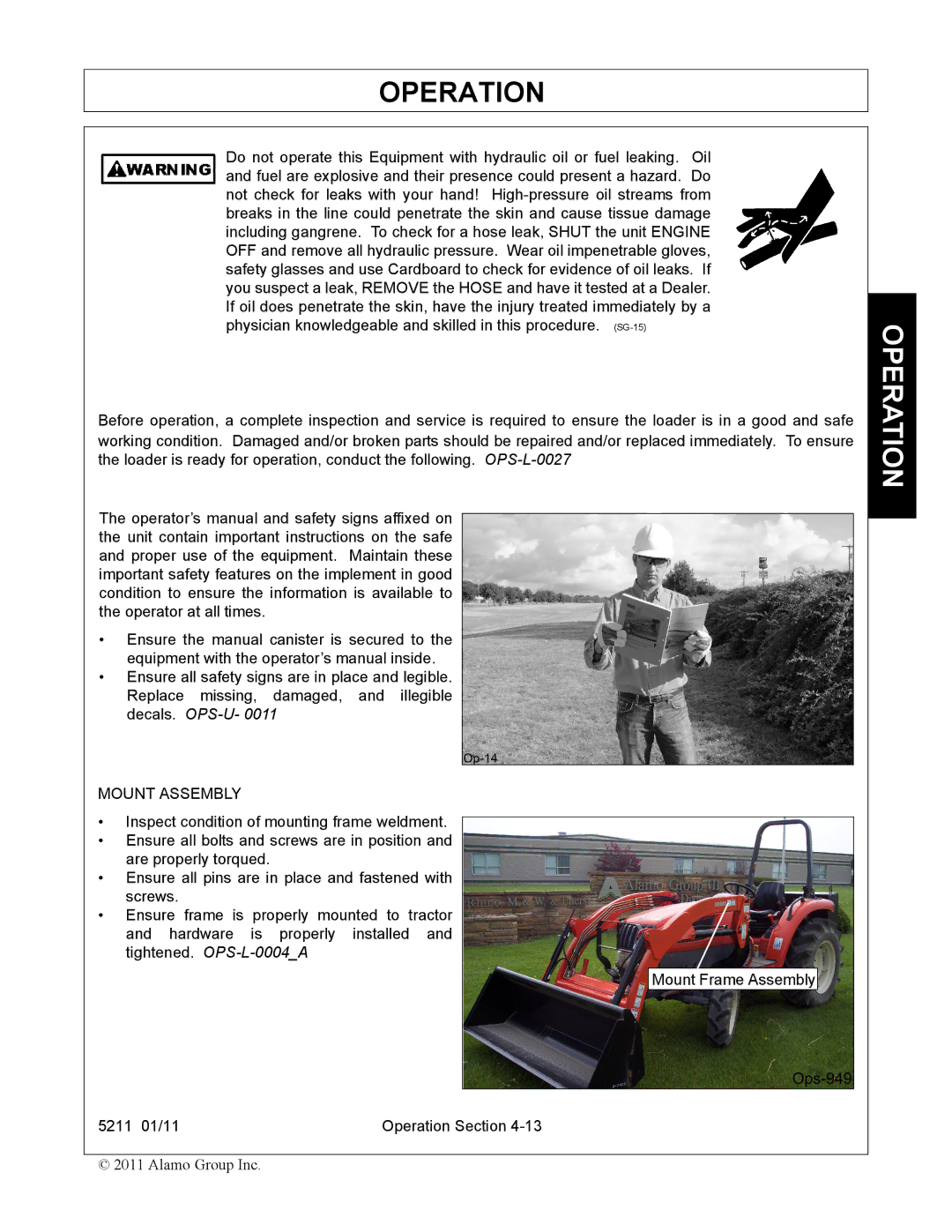

MOUNT ASSEMBLY

•Inspect condition of mounting frame weldment.

•Ensure all bolts and screws are in position and are properly torqued.

•Ensure all pins are in place and fastened with screws.

•Ensure frame is properly mounted to tractor and hardware is properly installed and tightened.

Mount Frame Assembly

5211 01/11 | Operation Section |

© 2011 Alamo Group Inc.