OPERATION

OPERATION

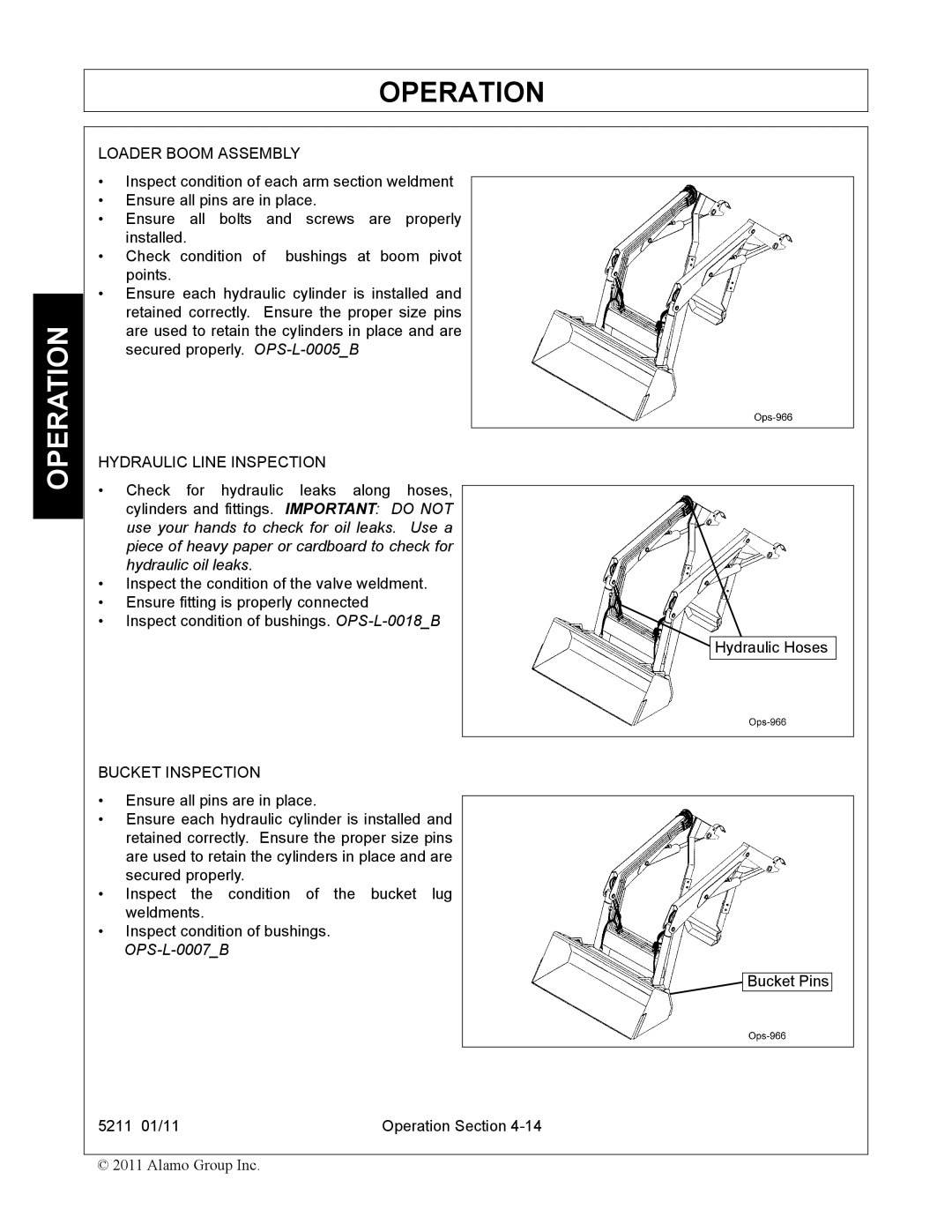

LOADER BOOM ASSEMBLY

•Inspect condition of each arm section weldment

•Ensure all pins are in place.

•Ensure all bolts and screws are properly installed.

•Check condition of bushings at boom pivot points.

•Ensure each hydraulic cylinder is installed and retained correctly. Ensure the proper size pins are used to retain the cylinders in place and are secured properly.

HYDRAULIC LINE INSPECTION

•Check for hydraulic leaks along hoses, cylinders and fittings. IMPORTANT: DO NOT use your hands to check for oil leaks. Use a piece of heavy paper or cardboard to check for hydraulic oil leaks.

•Inspect the condition of the valve weldment.

•Ensure fitting is properly connected

•Inspect condition of bushings.

BUCKET INSPECTION

•Ensure all pins are in place.

•Ensure each hydraulic cylinder is installed and retained correctly. Ensure the proper size pins are used to retain the cylinders in place and are secured properly.

•Inspect the condition of the bucket lug weldments.

•Inspect condition of bushings.

OPS-L-0007_B

![]() Hydraulic Hoses

Hydraulic Hoses

![]() Bucket Pins

Bucket Pins

5211 01/11 | Operation Section |

© 2011 Alamo Group Inc.