Maintenance & Care

Maintenance Schedule (Continued)

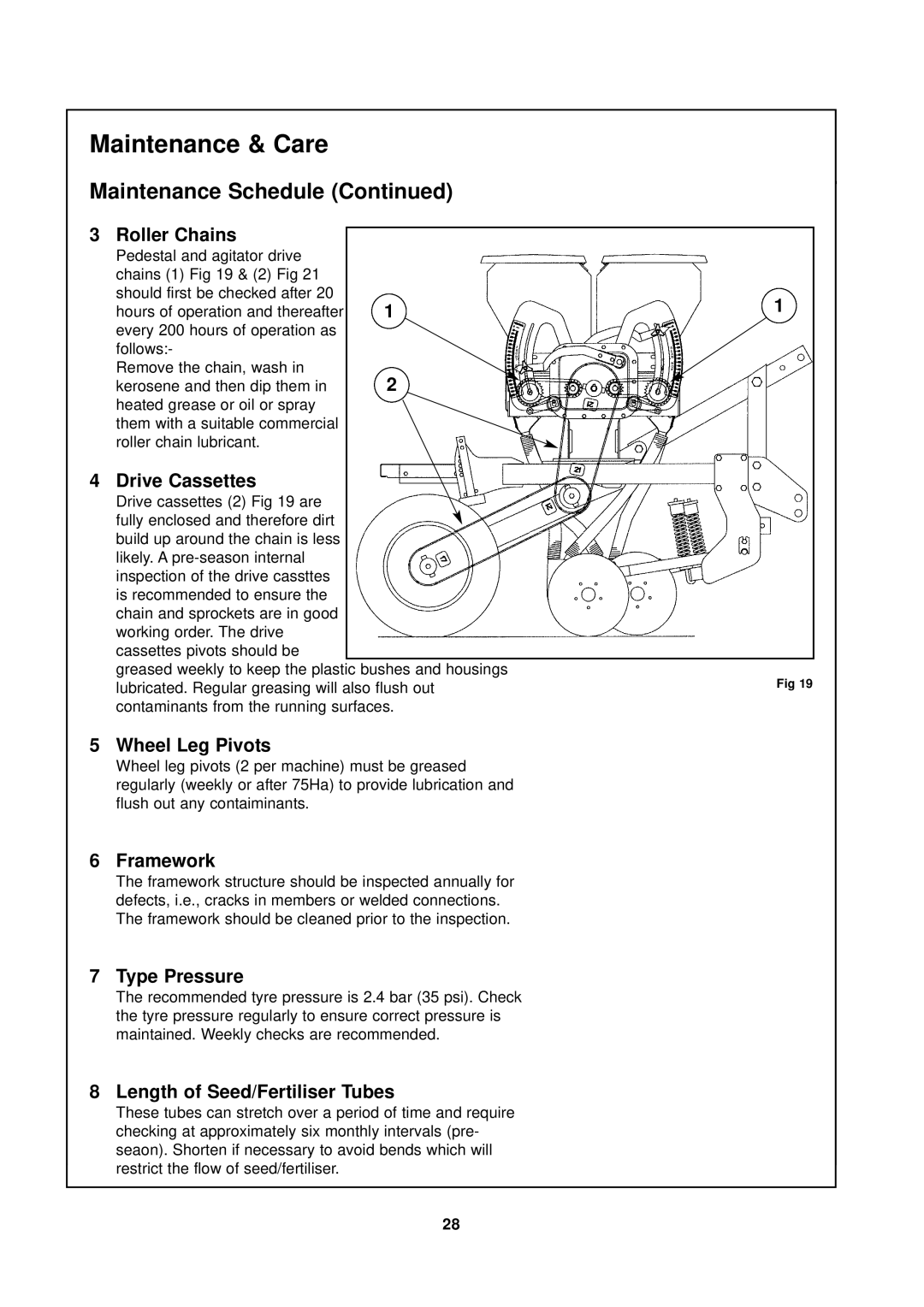

3 Roller Chains |

|

Pedestal and agitator drive |

|

chains (1) Fig 19 & (2) Fig 21 |

|

should first be checked after 20 | 1 |

hours of operation and thereafter | |

every 200 hours of operation as |

|

follows:- |

|

Remove the chain, wash in | 2 |

kerosene and then dip them in | |

heated grease or oil or spray |

|

them with a suitable commercial |

|

roller chain lubricant. |

|

4 Drive Cassettes

Drive cassettes (2) Fig 19 are fully enclosed and therefore dirt build up around the chain is less likely. A

greased weekly to keep the plastic bushes and housings lubricated. Regular greasing will also flush out contaminants from the running surfaces.

5 Wheel Leg Pivots

Wheel leg pivots (2 per machine) must be greased regularly (weekly or after 75Ha) to provide lubrication and flush out any contaiminants.

6 Framework

The framework structure should be inspected annually for defects, i.e., cracks in members or welded connections. The framework should be cleaned prior to the inspection.

7 Type Pressure

The recommended tyre pressure is 2.4 bar (35 psi). Check the tyre pressure regularly to ensure correct pressure is maintained. Weekly checks are recommended.

8 Length of Seed/Fertiliser Tubes

These tubes can stretch over a period of time and require checking at approximately six monthly intervals (pre- seaon). Shorten if necessary to avoid bends which will restrict the flow of seed/fertiliser.

1

Fig 19

28