Operation

WARNING!

■ Never permit bystanders or |

animals near the unit when |

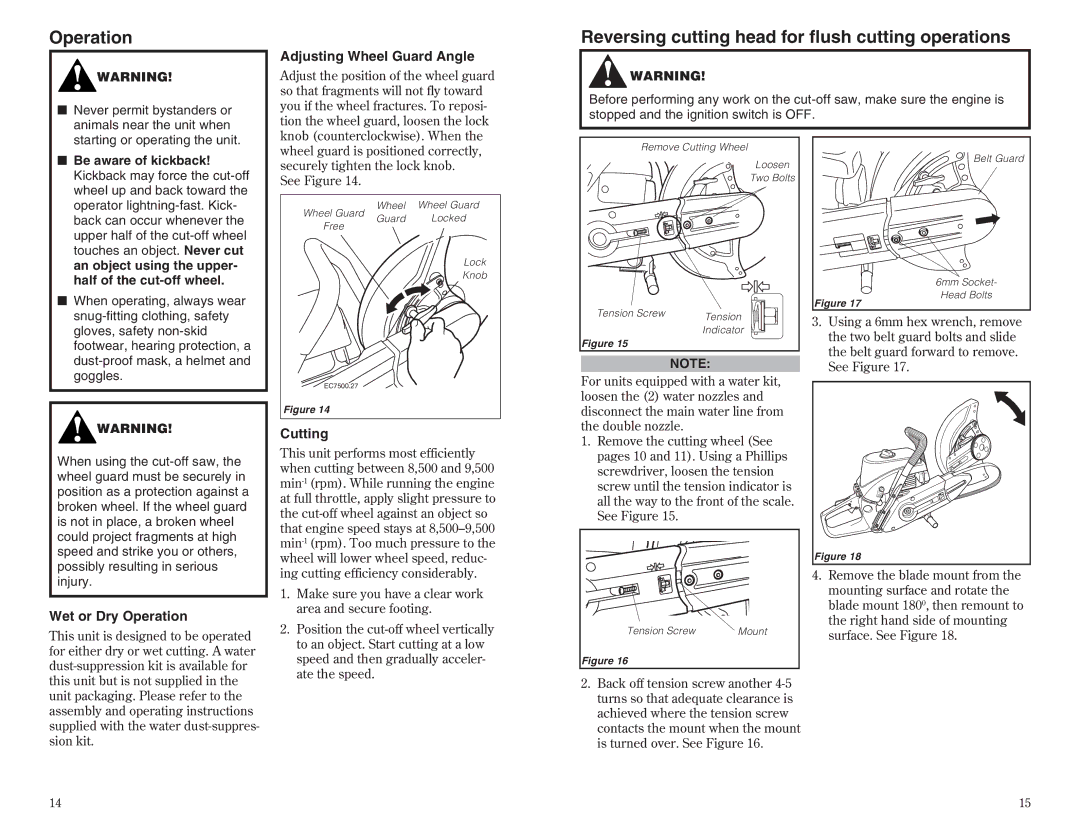

Adjusting Wheel Guard Angle

Adjust the position of the wheel guard so that fragments will not fly toward you if the wheel fractures. To reposi- tion the wheel guard, loosen the lock knob (counterclockwise). When the

Reversing cutting head for flush cutting operations

WARNING!

Before performing any work on the

starting or operating the unit. |

■ Be aware of kickback! |

Kickback may force the |

wheel up and back toward the |

operator |

back can occur whenever the |

upper half of the |

touches an object. Never cut |

an object using the upper- |

half of the |

■ When operating, always wear |

gloves, safety |

footwear, hearing protection, a |

goggles. |

WARNING!

When using the

Wet or Dry Operation

This unit is designed to be operated for either dry or wet cutting. A water

wheel guard is positioned correctly, securely tighten the lock knob. See Figure 14.

Wheel Guard | Wheel | Wheel Guard | |

Guard | Locked | ||

Free | |||

|

| ||

|

| Lock | |

|

| Knob | |

EC7500.27 |

|

| |

Figure 14 |

|

| |

Cutting |

|

|

This unit performs most efficiently when cutting between 8,500 and 9,500

1. | Make sure you have a clear work |

| area and secure footing. |

2. | Position the |

| to an object. Start cutting at a low |

| speed and then gradually acceler- |

| ate the speed. |

Remove Cutting Wheel | |

| Loosen |

| Two Bolts |

Tension Screw | Tension |

| |

| Indicator |

Figure 15 |

|

| NOTE: |

For units equipped with a water kit, loosen the (2) water nozzles and disconnect the main water line from the double nozzle.

1.Remove the cutting wheel (See pages 10 and 11). Using a Phillips screwdriver, loosen the tension screw until the tension indicator is all the way to the front of the scale. See Figure 15.

Tension Screw | Mount |

Figure 16 |

|

Belt Guard |

6mm Socket- |

Head Bolts |

Figure 17 |

3.Using a 6mm hex wrench, remove the two belt guard bolts and slide the belt guard forward to remove. See Figure 17.

Figure 18

4.Remove the blade mount from the mounting surface and rotate the blade mount 1800, then remount to the right hand side of mounting surface. See Figure 18.

this unit but is not supplied in the unit packaging. Please refer to the assembly and operating instructions supplied with the water

2.Back off tension screw another

14 | 15 |