Simatic

Industrial PC Simatic IPC427C

Legal information

Table of contents

Table of contents

105

Appendix

ESD guidelines

List of abbreviations

Index

Introduction

Preface

Contents format Table of Contents

Guideline to the Operating Instructions

Safety Instructions

General safety instructions

Repairs

System expansions

Battery

ESD directives

Description

Overview

Applications

Features

Basic data

Drives and storage media

Monitoring and safety functions

Basic data Ports

Software Operating systems

Windows Embedded Standard

Function Hard disk / SSD version Compact Flash card version

Activation of Horm and creation of a Hiber File

Design

External Design

Device components Pos Description

Ports and power supply

Connection components

On/Off switch

Position of on/off switch Description

Operator controls

Status displays

Status displays

Meaning

Application planning

Transport

Unpacking and checking the delivery unit

Unpacking the device

Noting the device identification data

COA Label Windows Embedded Standard

Ambient and Environmental Conditions

Installing/mounting

Horizontal preferred position Permitted temperatures

Vertical Power supply at the top

Permitted mounting positions

Upright mounting Permitted temperatures

Suspended

Mounting information

Mounting the device

Mounting methods

Mounting on DIN rails

Mounting the device on DIN rails

Steps for mounting on DIN rails

Installing/mounting 5.4 Mounting on DIN rails

Removing the device from the DIN rail

Installing brackets on the device

Steps for installing the mounting brackets

Mounting with mounting brackets

Removing mounting clamps from the device

Mounting/demounting the device

Mounting examples Material Bore diameter

Upright mounting

Mounting the vertical mounting bracket onto the device

Connecting

Connecting peripheral equipment

Connecting the 24 V DC power supply

Connecting

Steps for connecting the device to the 24 V DC power supply

To be noted before you connect the device

Protective ground connection

Protective earth terminal

Steps for connecting the USB strain-relief

USB strain-relief

Commissioning

Factory state

Connections before commissioning

Configuring the operating system

Commissioning Windows Embedded Standard

Basic commissioning initial startup

Requirements

Switch off the device

Commissioning Windows XP Professional

Switch off the device

Commissioning other operating systems

Commissioning guide

Additional information

Integration into an Automation System

Ethernet

RS232

Integration into an Automation System 8.1 Overview

Functions

Monitoring Functions

Simatic PC DiagBase software

Simatic PC DiagMonitor software

Temperature monitoring/display

Temperature monitoring

Watchdog WD

Function

Watchdog reactions

WD monitoring times

Function Command

Enhanced Write Filter EWF

Purpose and function

Set EWF

Special features for the use of Enhanced Write Filters EWF

Ewfmgr c -enable

Configuring Fbwf

File Based Write Filter Fbwf

Comparison between EWF and Fbwf

Functions

Sram buffer memory

Battery monitoring

Operation without monitor and keyboard

Expansions and Configurations

Open the device front panel

Tools

Preparation

Open the device

Steps in opening the device front panel

Installing the memory module

How to remove a memory module

Memory expansion

Memory expansion options

Installing a memory module

Display of the current memory configuration

How to install a memory module

Installing PCI-104 / PC/104 Plus modules

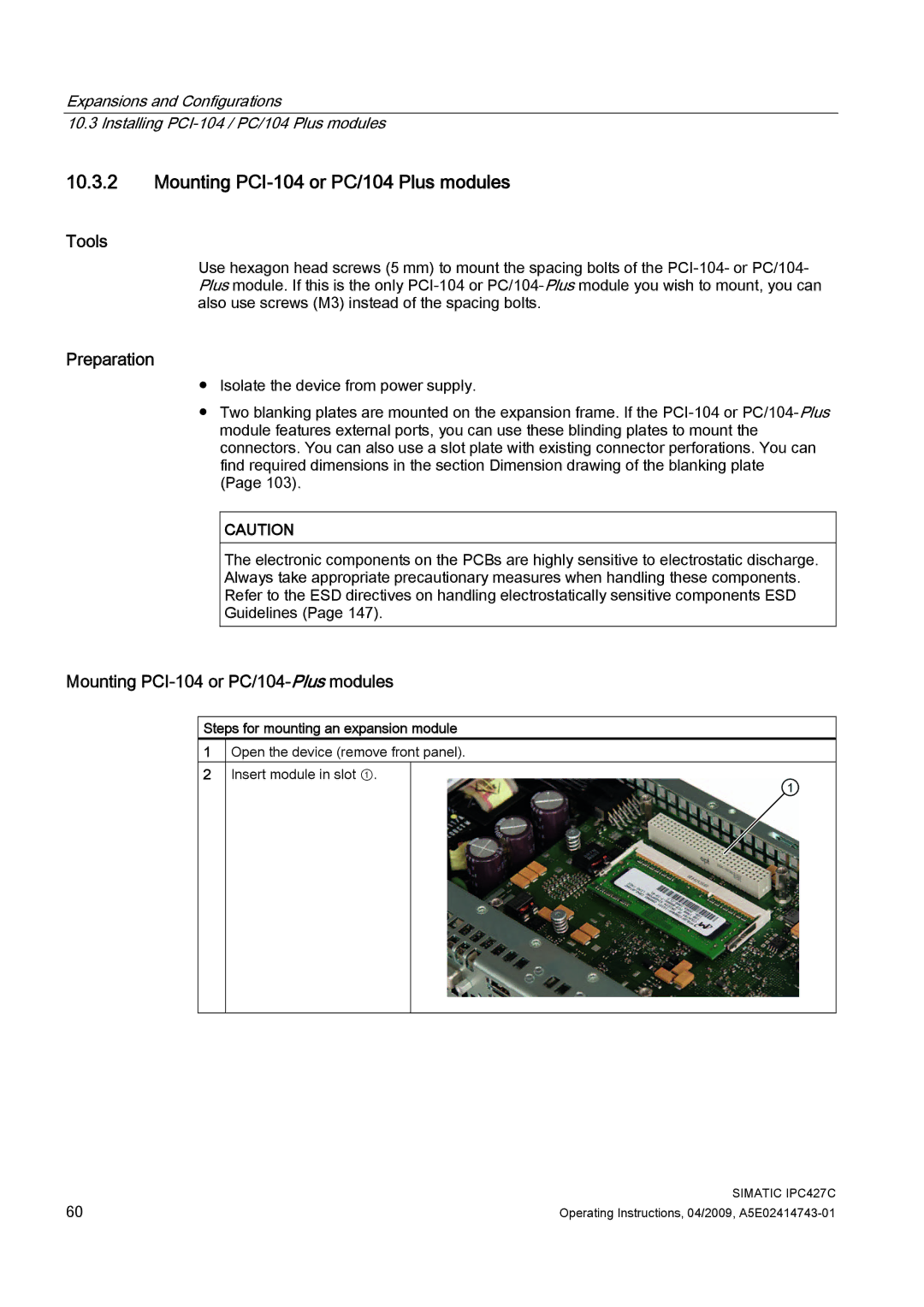

Mounting PCI-104 or PC/104 Plus modules

Mounting PCI-104 or PC/104-Plusmodules

Steps for mounting an expansion module

Configuring/installing a PCI-104 or PC/104-Plusmodule

Mounting additional PCI-104 or PC/104-Plusmodules

Installing/Removing Compact Flash Cards

Installation options for Compact Flash cards

Installing/removing an accessible Compact Flash card

Opening the module receptacle

Steps for opening the module receptacle

Installing the Compact Flash card

Steps for installing a Compact Flash card

Removing the Compact Flash card

Steps for removing a Compact Flash card

Installing/removing a built-in Compact Flash card

Steps for removing a built-in Compact Flash card

Maintenance and Service

Removing and Installing Hardware Components

Repairs

Carrying out repairs

Preventive maintenance

Component Exchange interval

How to remove a drive

Replacing hard disk or SSD drive

Removing drives

Installing a drive

Replace the backup battery

To be noted before you replace the battery

Disposal

Tool

Replacing the battery

Reconfiguring the Bios Setup

Steps for replacing the battery

Reinstalling the operating system

General installation procedure

Windows Embedded Standard

Restoring the factory state

Simatic IPC427C

Setting up the operating system with the Recovery CD

Windows XP Professional

Restoring the factory state

Maintenance and Service Reinstalling the operating system

Setting up the operating system via the Recovery CD/DVD

Booting with the Recovery CD/DVD

Partition setup

Installation of the operating system

CDDRIVE\MUI

Setting up the partitions under Windows Embedded Standard

Partitioning data media

Partitioning the Compact Flash card

Partitioning the hard disk

Setting up the partitions under Windows XP Professional

Partition Name Size File system

Installing drivers and software

Driver installation under Windows Embedded Standard

Installing drivers and software

Installing updates

Installing or updating application programs and drivers

Updating the operating system

Windows

Performing a Bios update

Download from Bios update

Data backup

Creating an image

Alarm, error and system messages

Boot error messages

On-screen error messages

On-screen error message Meaning / tip

Alarm, error and system messages 12.1 Boot error messages

Troubleshooting/FAQs

General problems

Problem Possible cause To correct or avoid error

Problems when using modules of third-party manufacturers

Technical specifications

General specifications

General specifications

Safety

General specifications Climatic Conditions

Horizontal mounting position

Vertical / portrait mounting position

General specifications Mech. Ambient conditions

Special Features

Motherboard

Drives / storage media

General specifications Ports

Status displays on the device

Power requirements of the components

Maximum power consumption of the auxiliary components

14.3 Integrated DC power supply

Technical specifications

Typical power consumption

Current consumption Power consumption At 24 V rated voltage

Dimension drawings

Overview of the dimensional drawings

Dimension drawings of the device

Dimensional drawing of the device Front view

Dimension drawings of the device with mounting brackets

100

101

Dimensional drawings of the device with expansion frames

Dimension drawing of the blanking plate

Dimensional drawing of the blinding plate

Dimension drawings Dimension drawing of the blanking plate

Detailed descriptions

Internal components

Overview of internal components

Technical features of the motherboard

Bios

Component Description Parameters Port

CPU

External ports

Overview

16.1.3.2 COM1/2

Port Position Description

DVI-I

16.1.3.5 USB

Ethernet RJ45 connection

Pin no Short description Description Input / output

USB port, 4 channel high current Pin no

Profibus

Can bus

Port Position Connector Description

Internal ports

16.1.4.2 Compact Flash card interface

PCI-104 or PC/104-Plus interface PCI part

PCI-104 or PCI part of the PC/104-Plus interface Pin no

Bios Setup

Bios Setup program

Changing the device configuration

Overview

Starting Bios Setup

Starting Bios Setup

Bios Setup menus

Menu layout

Menu Description

Settings in the main menu

Main menu

Field Meaning

By submenus

System time and date

Serial ATA Port 0, Serial ATA Port

Boot Options submenu

Keyboard Features submenu

Hardware Options submenu

Entry Meaning

PCI MPI / DP

Settings in the Advanced Menu

Advanced Menu

IO Device Configuration submenu

Sata Configuration submenu

Ahci

Security menu

Boot menu

12 Boot menu

Legacy

13 Legacy submenu

14 Boot Type Order field

129

Version menu

15 Version menu example

Exit Menu

Default Bios Setup entries

Documenting your device configuration

Bios Setup default settings

IO device configuration

Sata Configuration

Boot

Legacy Boot Type Order

Version

Simatic PC IPC427C Profibus

CPU ID

System resources

Currently allocated system resources

System resources used by the BIOS/DOS

PCI Interrupt Lines

Interrupt Interrupt type

16.4 I/O Address Areas

Overview of the internal module registers

Overview of the internal module registers

Addresses

Watchdog trigger register read only, address 066h

Meaning of the bits

Watchdog trigger register

Can base address register write only, address 066h

Output register LED 1 / 2 read/write, address 404Eh

Output register LED 1 / 2 read/write address 404Eh Bits

LED L2

Battery status tab read-only, address 50Fh

Sram address register

Sram address register

Connecting peripherals

Guidelines and declarations

EMC directive

Declaration of conformity

Approvals for the USA, Canada and Australia Product safety

Certificates and approvals

DIN ISO 9001 certificate

Software License Agreement

145

Service and support

Training center

Technical support

ESD Guidelines

Definition of ESD

Electrostatic charging

Basic protective measures against electrostatic discharge

Abbreviations

Abbreviation Term Meaning

FAQ

CRT

CSA

Dram

HDA

HDD

HMI

Html

NCQ

Nema

NMI

ODD

SO-DIMM

SOM

SPP

SSD

154

Glossary

Configuration files

Configuration software

CE marking

Chipset

Device configuration

Disc-at-once

Drivers

Dual Core CPU

ESD directive

File Based Write Filter EWF

Formatting

Gender changer

Image

Intel VT

InterfaceInterface

Interface, multi-point

License key

License key disk

Low-voltage directive

LPT interface

NEC Class

Operating system

Packet writing

PC card

PIC mode

PEG interface

Pixel

Plug&Play

Recovery CD

Reset

Restore DVD

PXE server

Setup Bios Setup

Troubleshooting

Scsi interface

Session at once

Warm restart

Wlan

166

Index

Can

Index

Simatic S7

170