Instruction Manual

4.0ALARM CALIBRATION

4.1Factory Alarm Calibration

The module has been factory calibrated to alarm as indicated in Table 4.1 and as marked on the cali- bration label shipped with the module.

Model | Time | Gas | cc/min | |

100sec. 100 ppm NH3 |

| 50 | ||

60 sec. 500 ppm R11 |

| 50 | ||

|

| 500 ppm R12 |

| 50 |

|

| 50 ppm R22 |

| 50 |

|

| 100 ppm R113 | 50 | |

|

| 70 ppm R123 |

| 50 |

|

| 50 ppm R134a | 50 | |

|

| 40 ppm R141b | 50 | |

|

| 40 ppm R142b | 50 | |

|

| 40 ppm R500 |

| 50 |

|

| 70 ppm R502 |

| 50 |

Table 4.1

4.2 Frequency of Alarm Calibration Check

The manufacturer recommends that the calibration

of each gas sensor module be verified monthly dur- ing the first three months of operation and then quar- terly. More frequent checks are necessary during periods of extreme humidity and temperature changes. The monitor should have operated con- tinuously (uninterrupted) for at least 24 hours prior to calibration adjustment.

4.3Alarm Calibration Check Process

The output signal of the gas sensor module is calibrated using a calibration gas mixture containing a known concentration of the gas of interest and a balance of air, or using a substitute gas. The concentration of the span gas must be equal to the alarm point desired.

The equivalent substitute gas is 80 ppm Hydrogen (H2) for the Model 2050 and 150 ppm Carbon Monoxide (CO) for the Model 2060.

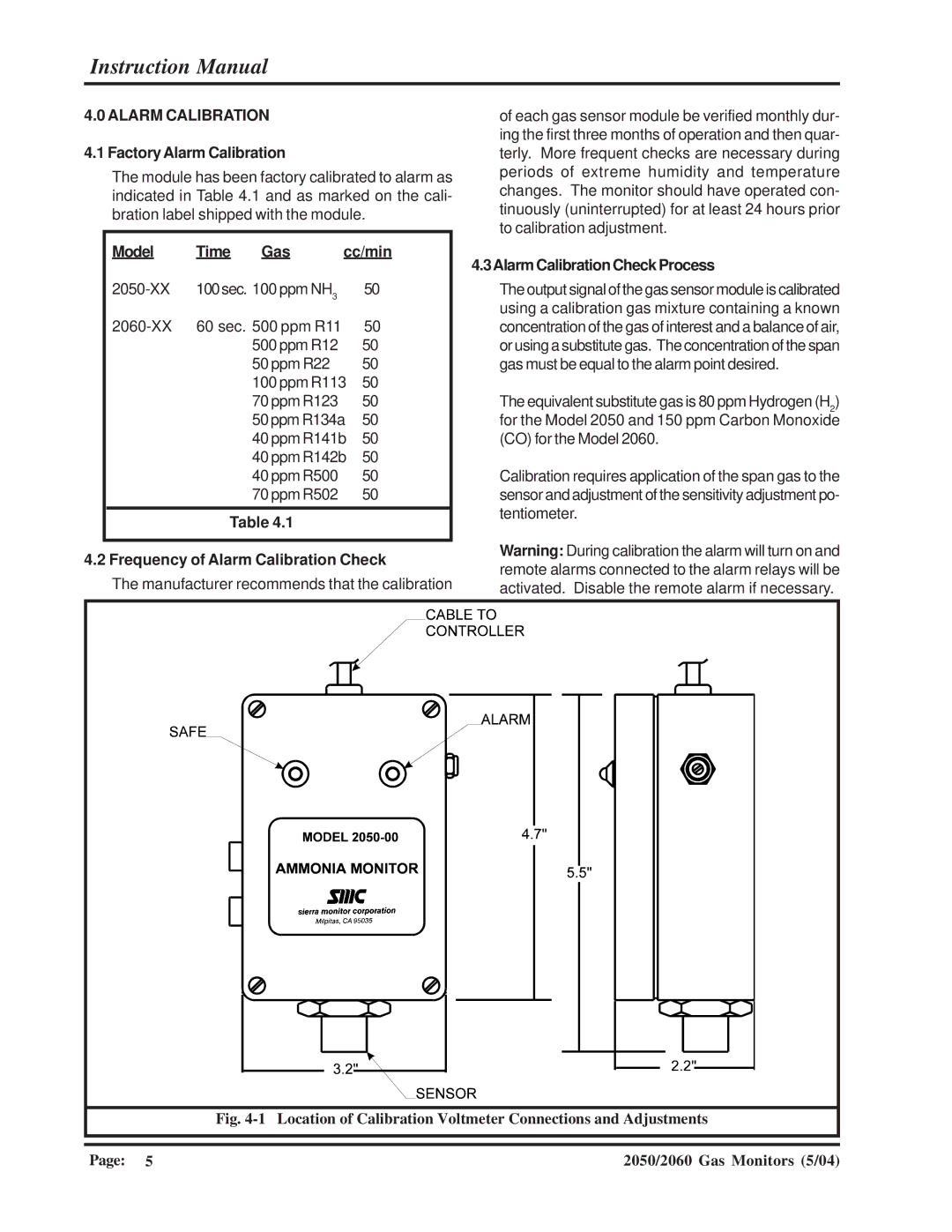

Calibration requires application of the span gas to the sensor and adjustment of the sensitivity adjustment po- tentiometer.

Warning: During calibration the alarm will turn on and remote alarms connected to the alarm relays will be activated. Disable the remote alarm if necessary.

|

| Fig. |

Page: | 5 | 2050/2060 Gas Monitors (5/04) |