Safety | 2 |

GENERAL SAFETY

Electrically powered utility pumps normally give many years of

1.Know the pump application, limitations, and poten- tial hazards.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Do not use in explosive atmospheres. Pump water only with this pump. Failure to follow this warning can result in personal injury and/or property damage.

Do not use in explosive atmospheres. Pump water only with this pump. Failure to follow this warning can result in personal injury and/or property damage.

2.Make certain power source conforms to requirements of your equipment.

3.Disconnect power before servicing.

4.Release all pressure within system before servicing any component.

5.Drain all water from system before servicing.

6.Secure discharge line before starting pump. An unse- cured discharge line will whip, possibly causing per- sonal injury and/or property damage.

7.Check hoses for weak or worn condition before each use, making certain all connections are secure.

8.Periodically inspect pump and system components. Keep pump and system free of debris and foreign objects. Perform routine maintenance as required.

9.Provide means of pressure relief on pumps whose dis- charge line can be

10.Personal Safety:

a.Wear safety glasses at all times when working with pumps.

b.Keep work area clean, uncluttered and properly lighted – replace all unused tools and equipment.

c.Keep visitors at a safe distance from the work area.

d.Make workshop

11.When wiring an electrically driven pump, follow all electrical and safety codes, as well as most recent National Electrical Code (NEC) and Occupational Safety and Health Act (OSHA).

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Pump motor is equipped with an auto- matic resetting thermal protector and may restart unexpectedly.

Pump motor is equipped with an auto- matic resetting thermal protector and may restart unexpectedly.

12.![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Risk of electric shock. This equipment is only for use on 115 volt (single phase) and is equipped with an approved

Risk of electric shock. This equipment is only for use on 115 volt (single phase) and is equipped with an approved

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() To reduce risk of electric shock, be cer- tain that it is connected to properly grounded,

To reduce risk of electric shock, be cer- tain that it is connected to properly grounded,

Where a

13.All wiring should be performed by a qualified electrician.

14.Protect electrical cord from sharp objects, hot sur- faces, oil, and chemicals. Avoid kinking cord. Replace or repair damaged or worn cords immediately.

15.Use wire of adequate size to minimize voltage drop at motor. Refer to most recent National Electrical Code.

16.Do not touch an operating motor. Modern motors can operate at high temperatures.

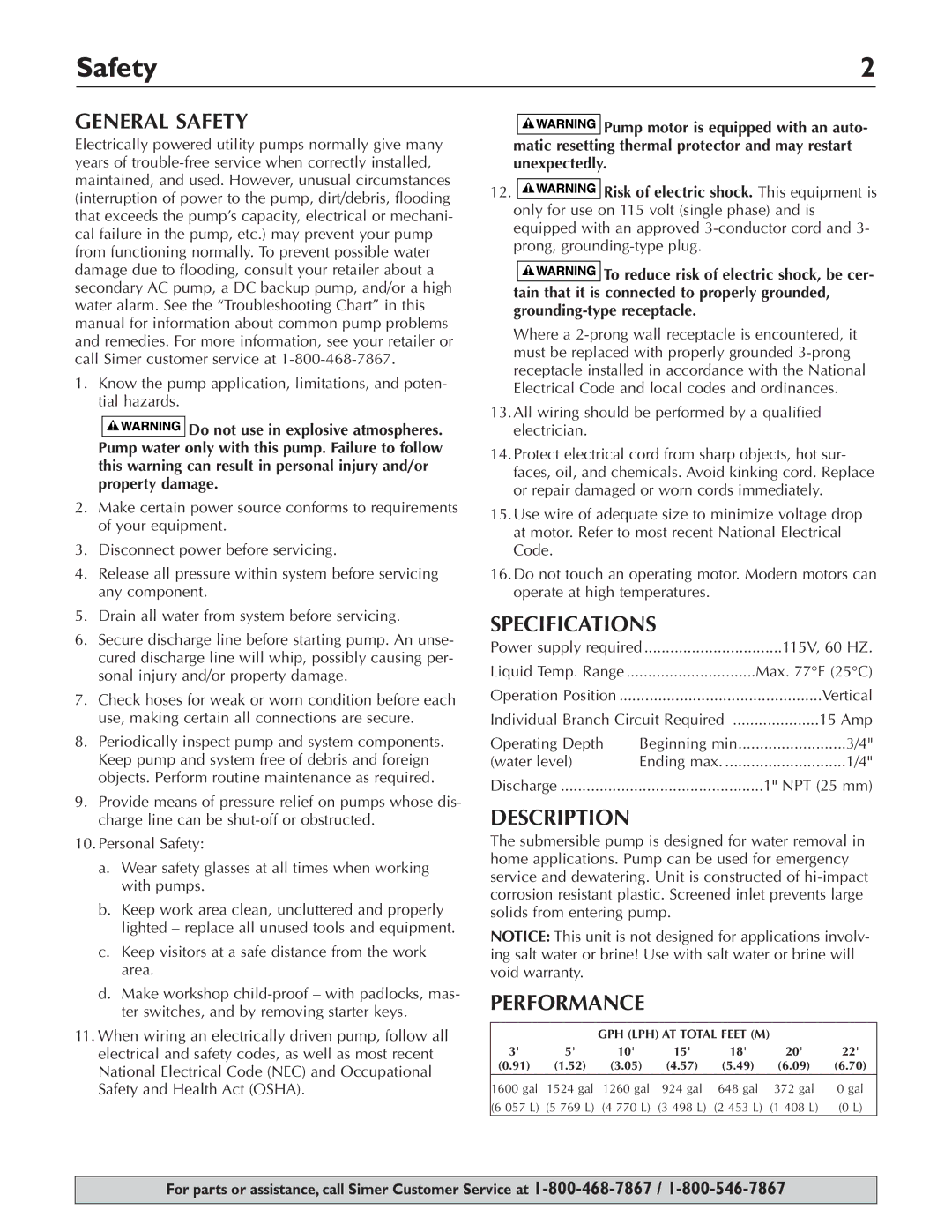

SPECIFICATIONS

Power supply required | 115V, 60 HZ. | |

Liquid Temp. Range | .............................. | Max. 77°F (25°C) |

Operation Position | Vertical | |

Individual Branch Circuit Required | 15 Amp | |

Operating Depth | Beginning min | 3/4" |

(water level) | Ending max | 1/4" |

Discharge | 1" NPT (25 mm) | |

DESCRIPTION

The submersible pump is designed for water removal in home applications. Pump can be used for emergency service and dewatering. Unit is constructed of

NOTICE: This unit is not designed for applications involv- ing salt water or brine! Use with salt water or brine will void warranty.

PERFORMANCE

|

| GPH (LPH) AT TOTAL FEET (M) |

|

| ||

3' | 5' | 10' | 15' | 18' | 20' | 22' |

(0.91) | (1.52) | (3.05) | (4.57) | (5.49) | (6.09) | (6.70) |

1600 gal | 1524 gal | 1260 gal | 924 gal | 648 gal | 372 gal | 0 gal |

(6 057 L) | (5 769 L) | (4 770 L) | (3 498 L) | (2 453 L) | (1 408 L) | (0 L) |

For parts or assistance, call Simer Customer Service at