2330, 2957-01, 2957, A5500, 2955-01 specifications

Simer Pumps has established itself as a trusted name in the water pump industry, providing high-quality products that cater to various applications. Among their lineup, the Simer Pumps 3075SS, 2955-01, A5500, 2957, and 2957-01 models stand out for their performance, durability, and innovative technologies.The Simer 3075SS is a stainless steel submersible pump designed for heavy-duty applications. Its robust construction offers exceptional corrosion resistance, making it ideal for residential and commercial use in demanding environments. This pump features an efficient motor that can handle both clear and slightly contaminated water, boasting a maximum flow rate of up to 75 gallons per minute. The automatic float switch ensures hands-free operation, activating the pump when water reaches a predetermined level.

The Simer 2955-01 is another reliable option, perfect for draining basements, flooded areas, or swimming pools. This submersible utility pump is lightweight and easy to transport, yet it doesn't compromise on efficiency. With a maximum flow rate of 30 gallons per minute, the 2955-01 is equipped with a powerful motor that enables continuous operation. The built-in overload protection safeguards the pump from potential damage, extending its lifespan.

Next in the lineup is the Simer A5500, a versatile high-capacity utility pump designed for more demanding applications. With its durable construction, this pump can handle larger volumes of water, making it suitable for commercial and industrial settings. The A5500 boasts a maximum pumping capacity of 70 gallons per minute, and its rugged design enables it to operate effectively in both fresh and saltwater environments. This model also comes with a thermal overload switch that provides additional protection against overheating.

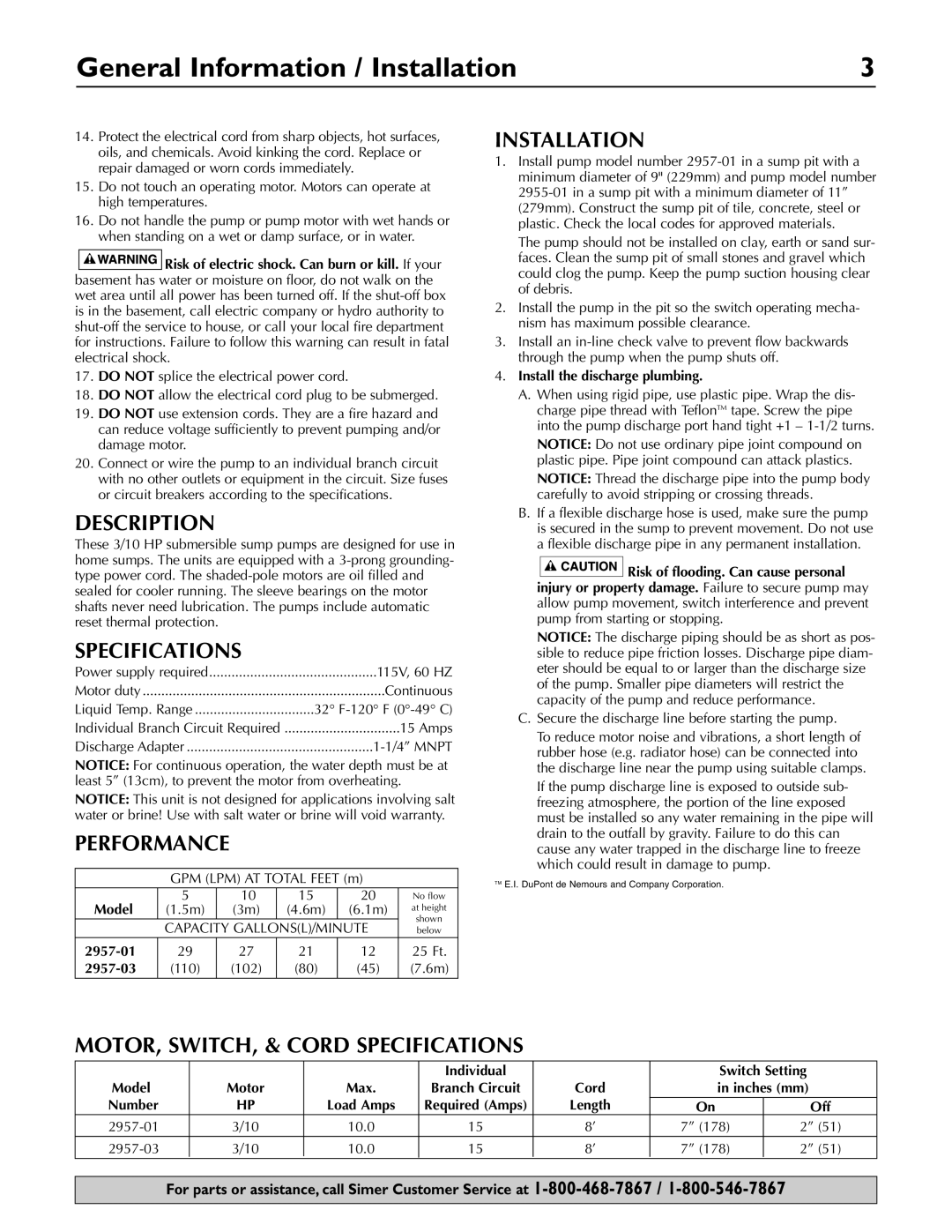

The Simer 2957 and 2957-01 models are designed with user convenience in mind. These submersible pumps guide water away from flooded areas efficiently. They provide a maximum flow rate of 30 gallons per minute and feature an adjustable float switch for customizable operation. The lightweight design makes them easy to transport, while the thermoplastic construction ensures longevity and resistance to corrosion.

In conclusion, Simer Pumps' models 3075SS, 2955-01, A5500, 2957, and 2957-01 exemplify the company’s commitment to quality and reliability. With their robust construction, intuitive features, and advanced technologies, these pumps meet the diverse needs of consumers and professionals alike, ensuring efficient water management across various applications.