6 |

|

The opening size recommendation just given is for guidance only. It is the installer’s responsibility to provide air for combus- tion and ventilation to all appliances, under all operating con- ditions, for each installation. See NFPA 31, latest edition for more specific details.

INSTALLING CONTROLS AND ACCESSORIES ON BOILER UNITS

Notes:Jacket must be installed on boiler units prior to installa- tion of trim.

WATER BOILER TRIM, see page 2, figures 1 and 2 for tap- ping locations.

WATER PIPING FOR HOT WATER HEATING BOILERS NOTE: On

I.CIRCULATING SYSTEM

A.FORCED CIRCULATION hot water heating system: Use the top tapping as supply tapping, and use the front or rear bottom tappings for the return.

B.A FLOW CONTROL VALVE will prevent gravity circula- tion and is required when an external tankless heater, an indirect water heater or multiple circulators are

installed.

II.AIR CONTROL SYSTEMS

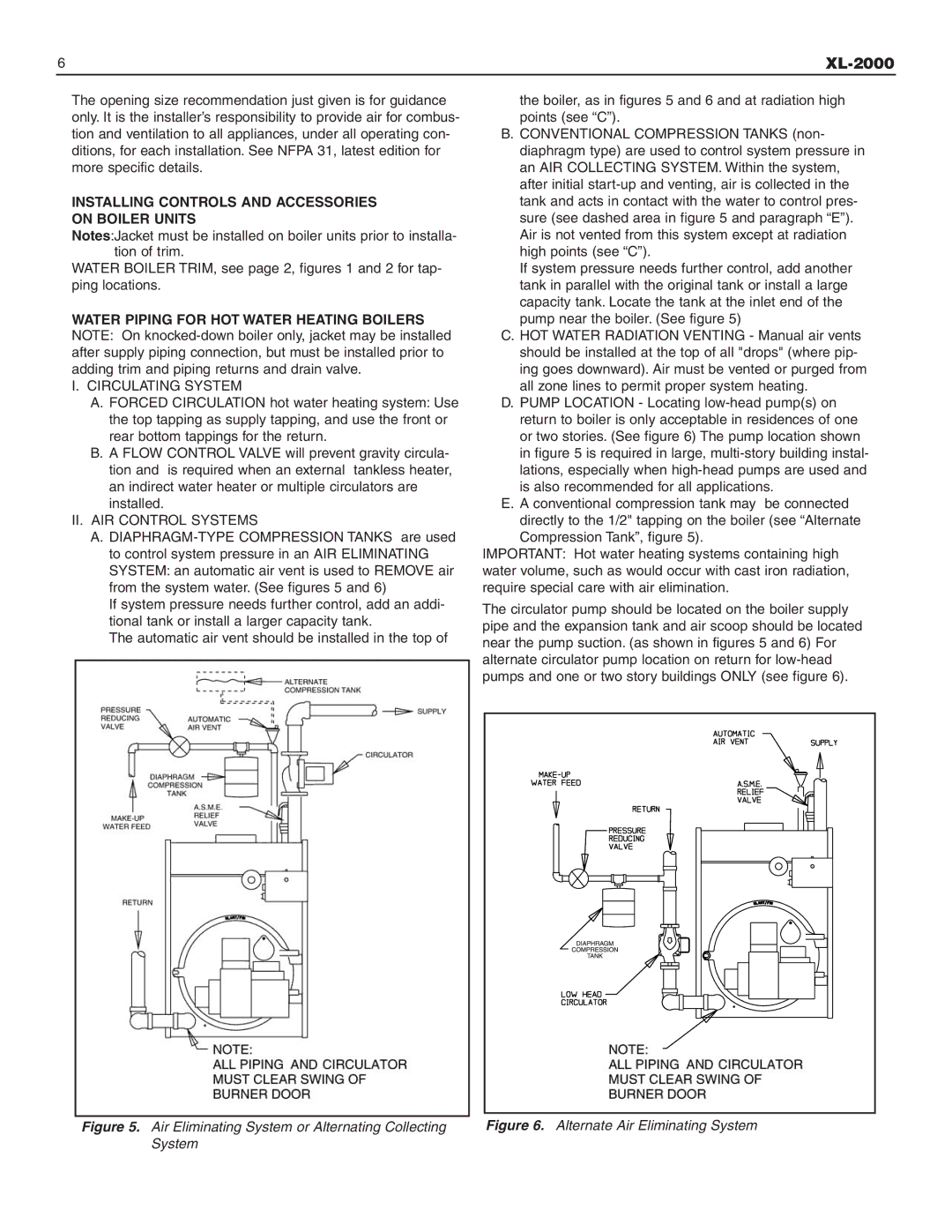

A.

If system pressure needs further control, add an addi- tional tank or install a larger capacity tank.

The automatic air vent should be installed in the top of

Figure 5. Air Eliminating System or Alternating Collecting System

the boiler, as in figures 5 and 6 and at radiation high points (see “C”).

B.CONVENTIONAL COMPRESSION TANKS (non- diaphragm type) are used to control system pressure in an AIR COLLECTING SYSTEM. Within the system, after initial

If system pressure needs further control, add another tank in parallel with the original tank or install a large capacity tank. Locate the tank at the inlet end of the pump near the boiler. (See figure 5)

C.HOT WATER RADIATION VENTING - Manual air vents should be installed at the top of all "drops" (where pip- ing goes downward). Air must be vented or purged from all zone lines to permit proper system heating.

D.PUMP LOCATION - Locating

E.A conventional compression tank may be connected

directly to the 1/2" tapping on the boiler (see “Alternate Compression Tank”, figure 5).

IMPORTANT: Hot water heating systems containing high water volume, such as would occur with cast iron radiation, require special care with air elimination.

The circulator pump should be located on the boiler supply pipe and the expansion tank and air scoop should be located near the pump suction. (as shown in figures 5 and 6) For alternate circulator pump location on return for

Figure 6. Alternate Air Eliminating System |