8 |

|

smoke and dry soot formation in the fire box.

F.If smoke reading is satisfactory, but CO2 can not be increased to a satisfactory level (12%) or overfire draft of 0.02" W.C. can not be obtained, check for proper sealing between sections, between the hinged burner mounting door and front section, around burner blast tube and around flue collector and collar. If seal is not satisfactory, reseal with furnace putty or silicone with a temperature rat- ing of at least 400° F. (All safety precautions indicated on material package must be followed.)

G.Once burner and draft have been set up, then smoke, CO2

and stack temperature should be checked and recorded. If smoke is greater than trace, review the burner instructions and replace the nozzle if necessary. Normal smoke to be expected is zero to a trace.

H. Make sure that the observation port cover is closed and the screw is tightened.

CLEANING AND FILLING A NEW WATER BOILER

I.There are a number of commercial preparations available from your distributor for cleaning and for corrosion protection conditioning the internal (waterside) surfaces of boilers. Follow the preparation manufacturer’s instructions.

DANGER: Use CAUTION when handling chemicals and draining hot water from a boiler. Scalding water and/or chemicals can cause permanent injury to the skin, eyes and respiratory system.

II.Filling and venting the water boiler after cleaning

A.Refill the system with fresh water.

B.Bring water temperature to at least 180° F promptly.

C.Circulate water through entire system.

D.Vent the system, including the radiation.

E.The boiler is now ready to be put into service or on standby.

F.If brand name

be followed.

|

|

|

|

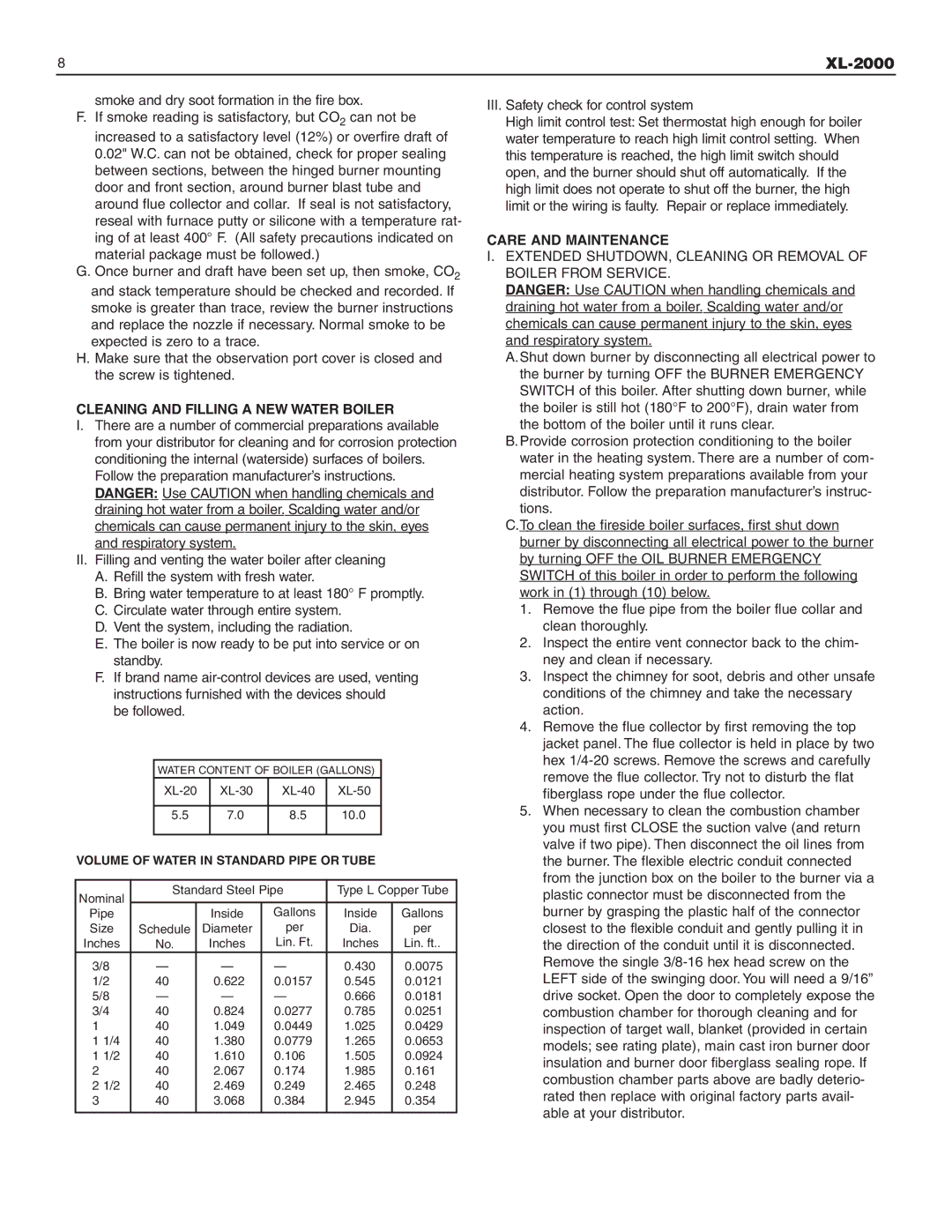

| WATER CONTENT OF BOILER (GALLONS) |

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

| 5.5 |

|

| 7.0 |

| 8.5 |

| 10.0 |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VOLUME OF WATER IN STANDARD PIPE OR TUBE |

|

|

|

|

|

| ||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

Nominal |

|

|

|

| Standard Steel Pipe |

|

| Type L Copper Tube |

| |||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

Pipe |

|

|

|

|

|

| Inside |

|

| Gallons |

|

| Inside |

|

|

| Gallons |

|

| |||

Size |

|

|

| Diameter |

|

| per |

|

| Dia. |

|

|

| per |

|

| ||||||

Schedule | ||||||||||||||||||||||

Inches |

|

| No. |

| Inches |

|

| Lin. Ft. |

|

| Inches |

|

|

| Lin. ft.. |

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3/8 |

|

|

| — |

| — |

|

| — |

| 0.430 |

|

| 0.0075 |

|

| ||||||

| 1/2 |

|

| 40 |

| 0.622 |

| 0.0157 |

| 0.545 |

|

| 0.0121 |

|

| |||||||

| 5/8 |

|

|

| — |

| — |

|

| — |

| 0.666 |

|

| 0.0181 |

|

| |||||

| 3/4 |

|

| 40 |

| 0.824 |

| 0.0277 |

| 0.785 |

|

| 0.0251 |

|

| |||||||

| 1 |

|

| 40 |

| 1.049 |

| 0.0449 |

| 1.025 |

|

| 0.0429 |

|

| |||||||

| 1 1/4 |

|

| 40 |

| 1.380 |

| 0.0779 |

| 1.265 |

|

| 0.0653 |

|

| |||||||

| 1 1/2 |

|

| 40 |

| 1.610 |

| 0.106 |

| 1.505 |

|

| 0.0924 |

|

| |||||||

| 2 |

|

| 40 |

| 2.067 |

| 0.174 |

| 1.985 |

|

| 0.161 |

|

| |||||||

| 2 1/2 |

|

| 40 |

| 2.469 |

| 0.249 |

| 2.465 |

|

| 0.248 |

|

| |||||||

| 3 |

|

| 40 |

| 3.068 |

| 0.384 |

| 2.945 |

|

| 0.354 |

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

III.Safety check for control system

High limit control test: Set thermostat high enough for boiler water temperature to reach high limit control setting. When this temperature is reached, the high limit switch should open, and the burner should shut off automatically. If the high limit does not operate to shut off the burner, the high limit or the wiring is faulty. Repair or replace immediately.

CARE AND MAINTENANCE

I.EXTENDED SHUTDOWN, CLEANING OR REMOVAL OF BOILER FROM SERVICE.

DANGER: Use CAUTION when handling chemicals and draining hot water from a boiler. Scalding water and/or chemicals can cause permanent injury to the skin, eyes and respiratory system.

A.Shut down burner by disconnecting all electrical power to the burner by turning OFF the BURNER EMERGENCY SWITCH of this boiler. After shutting down burner, while the boiler is still hot (180°F to 200°F), drain water from the bottom of the boiler until it runs clear.

B.Provide corrosion protection conditioning to the boiler water in the heating system. There are a number of com- mercial heating system preparations available from your distributor. Follow the preparation manufacturer’s instruc- tions.

C.To clean the fireside boiler surfaces, first shut down burner by disconnecting all electrical power to the burner by turning OFF the OIL BURNER EMERGENCY SWITCH of this boiler in order to perform the following work in (1) through (10) below.

1.Remove the flue pipe from the boiler flue collar and clean thoroughly.

2.Inspect the entire vent connector back to the chim- ney and clean if necessary.

3.Inspect the chimney for soot, debris and other unsafe conditions of the chimney and take the necessary action.

4.Remove the flue collector by first removing the top jacket panel. The flue collector is held in place by two hex

5.When necessary to clean the combustion chamber you must first CLOSE the suction valve (and return valve if two pipe). Then disconnect the oil lines from the burner. The flexible electric conduit connected from the junction box on the boiler to the burner via a plastic connector must be disconnected from the burner by grasping the plastic half of the connector closest to the flexible conduit and gently pulling it in the direction of the conduit until it is disconnected. Remove the single