4 |

|

tion, heavy sooting and health hazards. Any

DO NOT vent this boiler to the same chimney flue used by a fireplace or coal or wood burning furnace or boiler. The draft* produced by solid fueled devices varies tremendously between high fire and low fire:

In modern, weather stripped,

* Draft is negative or suction pressure

will create a downdraft in the

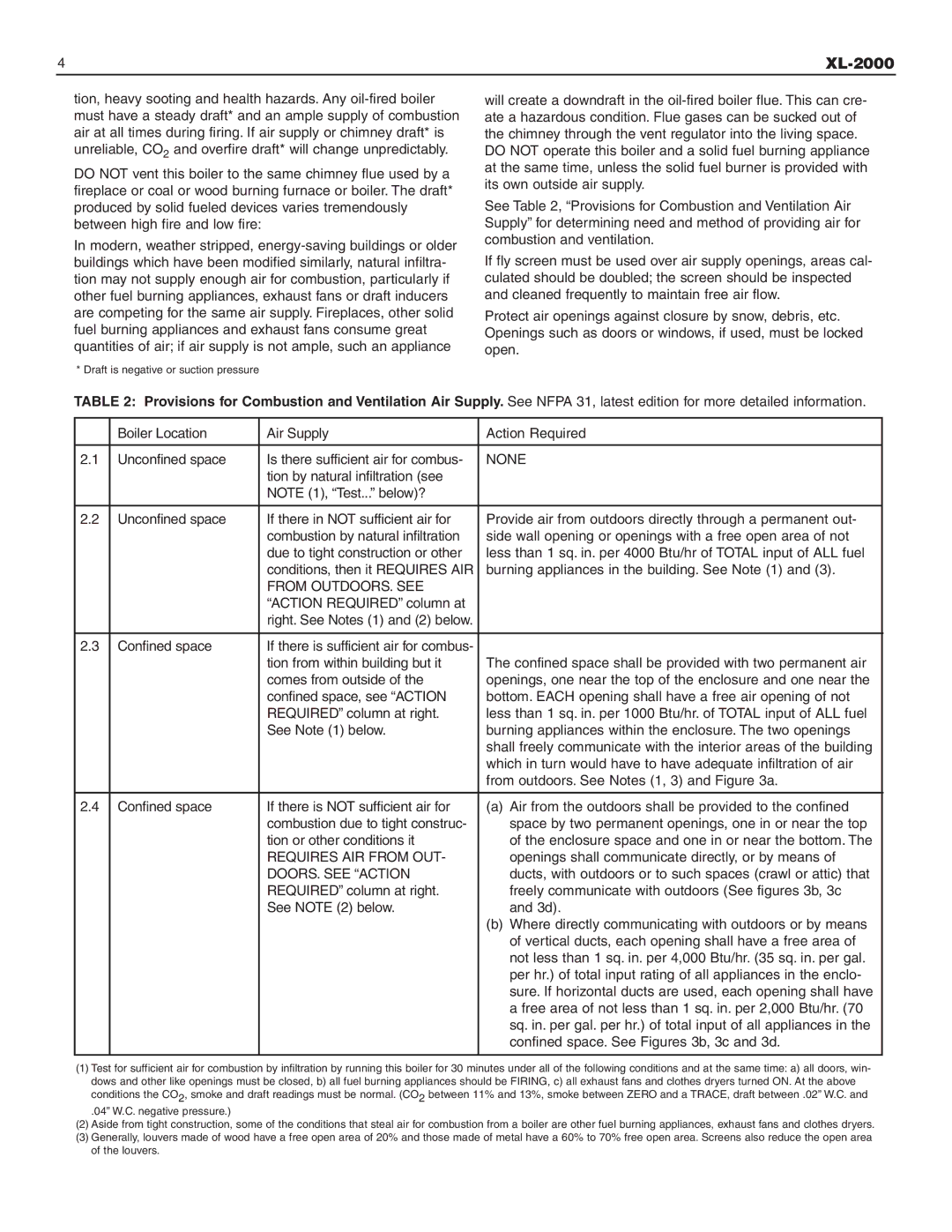

See Table 2, “Provisions for Combustion and Ventilation Air Supply” for determining need and method of providing air for combustion and ventilation.

If fly screen must be used over air supply openings, areas cal- culated should be doubled; the screen should be inspected and cleaned frequently to maintain free air flow.

Protect air openings against closure by snow, debris, etc. Openings such as doors or windows, if used, must be locked open.

TABLE 2: Provisions for Combustion and Ventilation Air Supply. See NFPA 31, latest edition for more detailed information.

|

|

|

|

|

|

|

|

|

| Boiler Location | Air Supply |

|

| Action Required |

|

|

|

|

|

|

|

|

|

| 2.1 | Unconfined space | Is there sufficient air for combus- |

|

| NONE |

|

|

|

| tion by natural infiltration (see |

|

|

|

|

|

|

| NOTE (1), “Test...” below)? |

|

|

|

|

|

|

|

|

|

|

|

|

| 2.2 | Unconfined space | If there in NOT sufficient air for |

|

| Provide air from outdoors directly through a permanent out- |

|

|

|

| combustion by natural infiltration |

|

| side wall opening or openings with a free open area of not |

|

|

|

| due to tight construction or other |

|

| less than 1 sq. in. per 4000 Btu/hr of TOTAL input of ALL fuel |

|

|

|

| conditions, then it REQUIRES AIR |

|

| burning appliances in the building. See Note (1) and (3). |

|

|

|

| FROM OUTDOORS. SEE |

|

|

|

|

|

|

| “ACTION REQUIRED” column at |

|

|

|

|

|

|

| right. See Notes (1) and (2) below. |

|

|

|

|

|

|

|

|

|

|

|

|

| 2.3 | Confined space | If there is sufficient air for combus- |

|

|

|

|

|

|

| tion from within building but it |

|

| The confined space shall be provided with two permanent air |

|

|

|

| comes from outside of the |

|

| openings, one near the top of the enclosure and one near the |

|

|

|

| confined space, see “ACTION |

|

| bottom. EACH opening shall have a free air opening of not |

|

|

|

| REQUIRED” column at right. |

|

| less than 1 sq. in. per 1000 Btu/hr. of TOTAL input of ALL fuel |

|

|

|

| See Note (1) below. |

|

| burning appliances within the enclosure. The two openings |

|

|

|

|

|

|

| shall freely communicate with the interior areas of the building |

|

|

|

|

|

|

| which in turn would have to have adequate infiltration of air |

|

|

|

|

|

|

| from outdoors. See Notes (1, 3) and Figure 3a. |

|

|

|

|

|

|

|

|

|

| 2.4 | Confined space | If there is NOT sufficient air for |

|

| (a) Air from the outdoors shall be provided to the confined |

|

|

|

| combustion due to tight construc- |

|

| space by two permanent openings, one in or near the top |

|

|

|

| tion or other conditions it |

|

| of the enclosure space and one in or near the bottom. The |

|

|

|

| REQUIRES AIR FROM OUT- |

|

| openings shall communicate directly, or by means of |

|

|

|

| DOORS. SEE “ACTION |

|

| ducts, with outdoors or to such spaces (crawl or attic) that |

|

|

|

| REQUIRED” column at right. |

|

| freely communicate with outdoors (See figures 3b, 3c |

|

|

|

| See NOTE (2) below. |

|

| and 3d). |

|

|

|

|

|

|

| (b) Where directly communicating with outdoors or by means |

|

|

|

|

|

|

| of vertical ducts, each opening shall have a free area of |

|

|

|

|

|

|

| not less than 1 sq. in. per 4,000 Btu/hr. (35 sq. in. per gal. |

|

|

|

|

|

|

| per hr.) of total input rating of all appliances in the enclo- |

|

|

|

|

|

|

| sure. If horizontal ducts are used, each opening shall have |

|

|

|

|

|

| |||

|

|

|

|

|

| a free area of not less than 1 sq. in. per 2,000 Btu/hr. (70 |

|

|

|

|

|

|

| sq. in. per gal. per hr.) of total input of all appliances in the |

|

|

|

|

|

|

| confined space. See Figures 3b, 3c and 3d. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(1)Test for sufficient air for combustion by infiltration by running this boiler for 30 minutes under all of the following conditions and at the same time: a) all doors, win- dows and other like openings must be closed, b) all fuel burning appliances should be FIRING, c) all exhaust fans and clothes dryers turned ON. At the above conditions the CO2, smoke and draft readings must be normal. (CO2 between 11% and 13%, smoke between ZERO and a TRACE, draft between .02” W.C. and

.04” W.C. negative pressure.)

(2)Aside from tight construction, some of the conditions that steal air for combustion from a boiler are other fuel burning appliances, exhaust fans and clothes dryers.

(3)Generally, louvers made of wood have a free open area of 20% and those made of metal have a 60% to 70% free open area. Screens also reduce the open area of the louvers.